- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

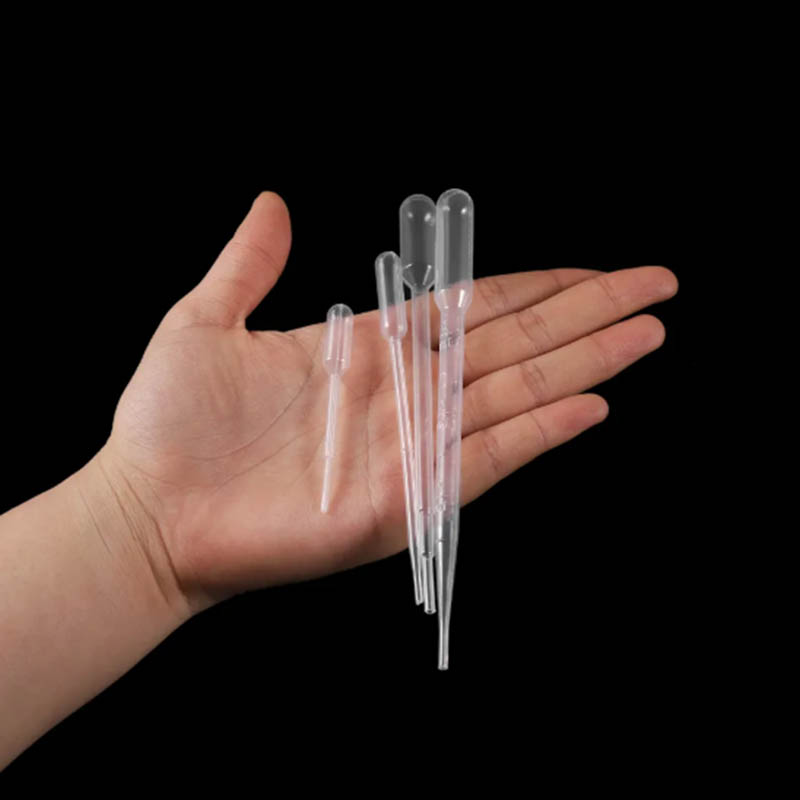

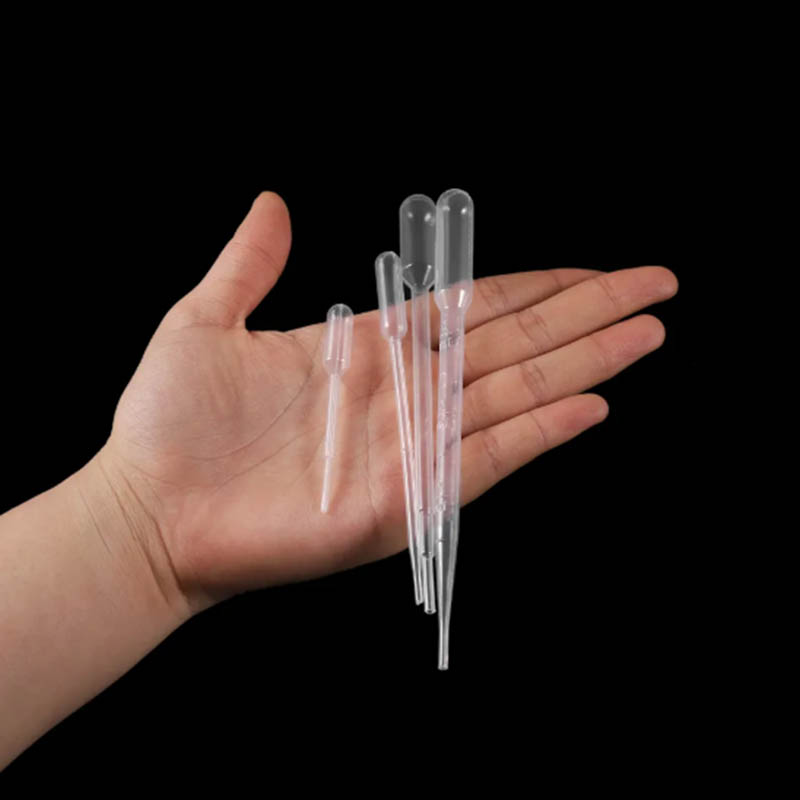

Plastic Pipettes

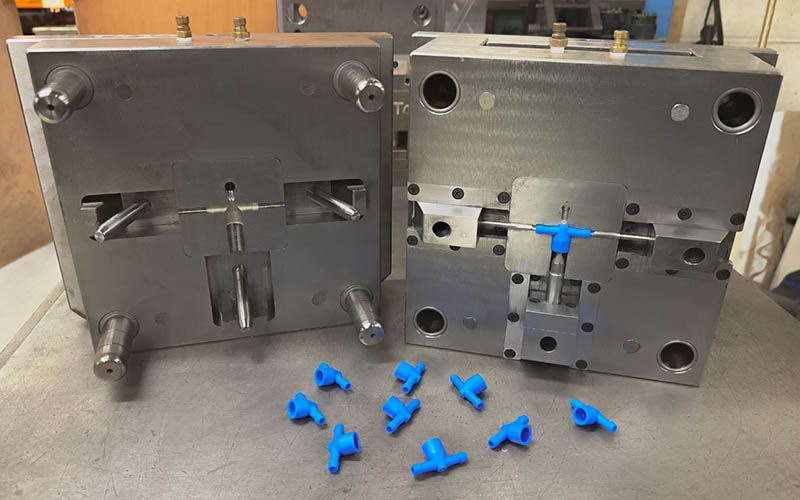

Ningbo P&M specializes in the manufacturing of Plastic pipettes and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic pipette solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic pipettes sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic pipettes. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.

Send Inquiry

Types and Applications of Plastic Pipettes

Plastic pipettes are essential laboratory tools used for precise liquid handling, transfer, and dispensing in scientific research, medical diagnostics, and other laboratory procedures. These pipettes come in various types and designs, each tailored for specific applications based on their features and capabilities. Let's explore the types, applications, and significance of plastic pipettes, followed by an overview of Ningbo P&M's strengths and advantages in injection molding plastic pipettes.

Types of Plastic Pipettes:

1.Transfer Pipettes: Disposable pipettes for transferring small volumes of liquids accurately.

2.Graduated Pipettes: Pipettes with volume markings for precise measurement and dispensing.

3.Serological Pipettes: Long, slender pipettes used in cell culture and microbiology applications.

4.Micropipettes: Precision pipettes for handling microliter volumes with high accuracy.

5.Pasteur Pipettes: Fine-tipped pipettes for transferring small quantities of liquids.

6.Filter Pipettes: Pipettes with built-in filters for protecting against liquid carryover.

7.Positive Displacement Pipettes: Pipettes suitable for viscous or volatile liquids with low surface tension.

8.Multichannel Pipettes: Pipettes with multiple channels for simultaneous dispensing of multiple samples.

9.Electronic Pipettes: Battery-operated pipettes with electronic controls for accurate and repetitive dispensing.

10.Variable Volume Pipettes: Pipettes with adjustable volume settings for flexibility in liquid handling.

Applications of Plastic Pipettes:

Sample Transfer: Used for transferring samples, reagents, and solutions in various laboratory procedures.

Cell Culture: Essential for cell seeding, media changes, and other cell culture applications.

Titration: Utilized for titrating solutions and dispensing precise volumes during chemical analyses.

PCR and Molecular Biology: Integral in DNA amplification, PCR setups, and other molecular biology techniques.

Microbiology: Employed for microbial inoculation, dilution series, and other microbiological tasks.

Biochemistry: Used for enzyme assays, protein quantification, and other biochemical analyses.

Drug Discovery: Commonly used in drug screening, compound dispensing, and assay development.

Quality Control: Essential for quality assurance processes in industries such as pharmaceuticals and biotechnology.

Clinical Diagnostics: Utilized in medical laboratories for sample handling, testing, and diagnostics.

Research and Development: Integral in research labs for various scientific investigations and experiments.

Ningbo P&M's Advantages in Injection Molding Plastic Pipettes:

Ningbo P&M is a leading manufacturer specializing in injection molding and the production of high-quality plastic laboratory equipment, including plastic pipettes. The company's expertise in plastic pipette manufacturing is supported by several key advantages that set them apart in the industry.

Advantages in Plastic Pipette Manufacturing:

1.Customization Capabilities: Ningbo P&M offers extensive customization options for plastic pipettes, including volume capacities, tip designs, graduations, and material selection, to meet specific customer requirements.

2.Advanced Injection Molding Technology: Leveraging state-of-the-art injection molding technology, Ningbo P&M ensures the production of precise, reliable, and high-performance plastic pipettes with consistent quality.

3.Material Expertise: With in-depth knowledge of plastic materials and their properties, Ningbo P&M selects the most suitable materials for each plastic pipette application, considering factors such as clarity, chemical resistance, and durability.

4.Quality Assurance: Implementing stringent quality control measures throughout the manufacturing process, Ningbo P&M guarantees that each plastic pipette meets industry standards for accuracy, reliability, and safety.

5.Cost-Effective Solutions: By optimizing production processes and efficiency, Ningbo P&M delivers cost-effective plastic pipette solutions without compromising on quality or functionality.

6.Innovative Designs: With a team of experienced engineers and designers, Ningbo P&M focuses on developing innovative plastic pipette designs that enhance accuracy, usability, and performance in laboratory settings.

|

Product Name |

Plastic pipettes |

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |