- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

Plastic Cup Molding

In the context of rapid technological development, plastic cup molding manufacturers are taking big strides towards cutting-edge technologies such as intelligence, precision, and greenness. The application of intelligent technology has brought revolutionary changes to injection mold manufacturing.

Send Inquiry

Precision manufacturing technology is also an important direction for future development. With the continuous improvement of precision requirements for plastic products in various industries, the manufacturing precision of plastic cup injection molds must also be improved accordingly.

The concept of green manufacturing is increasingly deeply rooted in people's hearts, and plastic cup injection mold manufacturers are also actively responding to this trend. In terms of raw material selection, more and more manufacturers are adopting environmentally friendly materials such as biodegradable plastics, recycled plastics, etc. to reduce environmental pollution.

For Plastic cup molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.

P&M Plastic cup molding Introduction

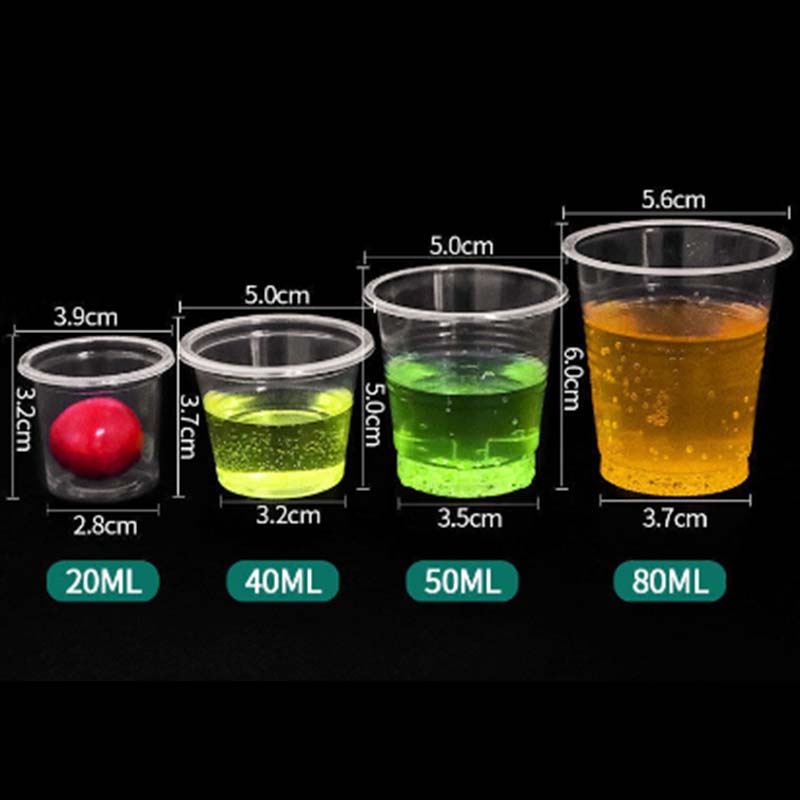

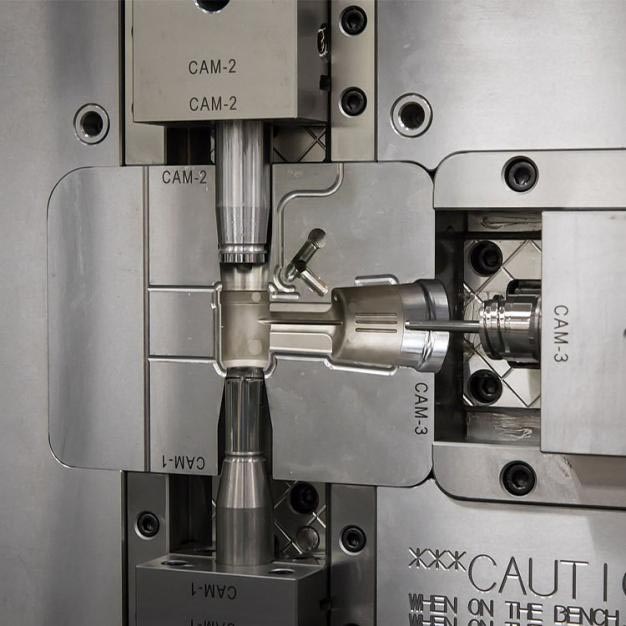

Mold design is the primary step in the manufacturing of plastic cup injection molds. The selection of materials is crucial in the design process. P&M will choose materials such as medium carbon steel and medium carbon alloy steel, which have good mechanical processing performance and can meet the high-precision processing requirements in the mold manufacturing process.

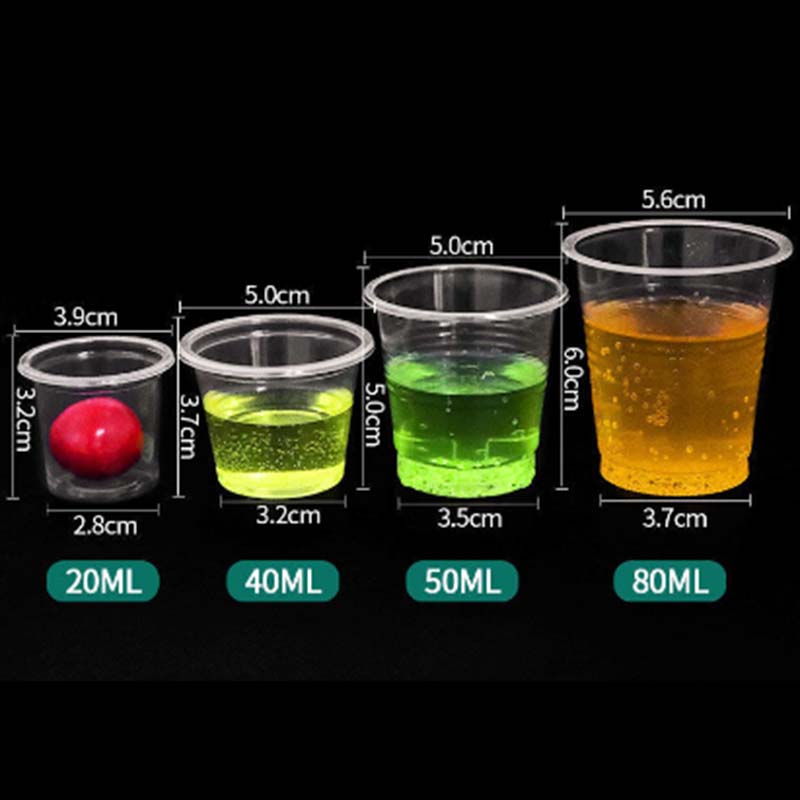

The size and shape design of the mold should be closely determined based on the specific requirements of the plastic cup. The size parameters such as capacity, height, and diameter of the cup directly determine the size and shape of the mold cavity. The appearance design of the cup, such as whether it has patterns, curvature, etc., will also affect the structural design of the mold. In the design process of P&M, factors such as the parting surface and demolding method of the mold should be fully considered to ensure that the mold can be opened and closed smoothly during the production process, and plastic products can be demolded smoothly.

P&M Plastic cup molding Parameter (Specification)

|

Mould Name |

Plastic cup molding |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Moud precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

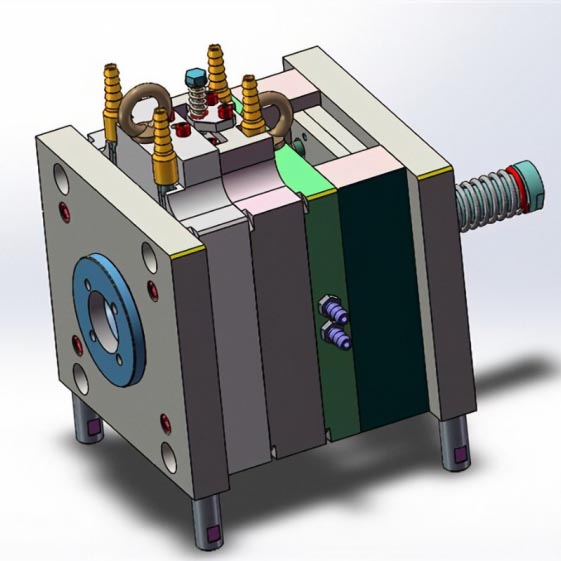

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Origin |

Made in China |

|

Runner |

Cold runner and hot runner |

|

Package |

Carton |

P&M Plastic cup molding Feature And Application

Plastic cups, as a common item in daily life, have a wide range of functions. In terms of beverage storage, it can meet people's needs for various hot and cold drinks. Whether it's a steaming cup of coffee in the morning, it provides energy to start a day full of vitality; During the scorching summer, a glass of fruit juice with ice can bring a cool and refreshing feeling, and even plastic cups can perfectly handle it. Its material has good thermal insulation performance, which can effectively prevent the rapid loss of heat and maintain the temperature of hot drinks; For cold drinks, it can reduce the condensation of water droplets on the cup wall and avoid wetting the tabletop.

In terms of portability, plastic cups exhibit unique advantages. Its material is lightweight, and its weight is lighter compared to glass cups, making it convenient for people to carry around. Whether traveling, commuting to work, or exercising outdoors, plastic cups can be easily placed in backpacks or pockets to meet drinking needs anytime, anywhere. Plastic cups also have a certain degree of drop resistance, and even if accidentally dropped, they are not easily broken like glass cups, greatly reducing the risk of wear and tear during use.

Plastic cups can be seen everywhere in office settings. It provides a convenient way for busy office workers to drink water at any time during work breaks, keeping their bodies hydrated and improving work efficiency. In the conference room, disposable plastic cups provide convenient drinking options for conference participants, avoiding the risk of cross infection. At school, students use plastic cups to conveniently replenish water and meet their physiological needs during learning and exercise, whether in the classroom, library, or playground.

In the catering industry, plastic cups are also widely used. Restaurants, cafes, fast food restaurants, and other places often use plastic cups to serve drinks to customers. These cups can not only be customized in different shapes, colors, and logos according to the needs of merchants to promote and advertise, but also provide customers with a better user experience by matching different cup lids, straws, and other accessories.

P&M Plastic cup molding Details

Customization Process

Factory&About US

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

Product packaging

Packaging according to your needs

1. By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS.

2. By sea ,the delivery time is based on your port.

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

P&M Children's Bowl, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

The path of a child's growth is paved with bricks and tiles.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.What can you buy from us?

Mould,Plastic Product,Metal Product,Dental Product,CNC machining.

4.Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6.What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.