- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

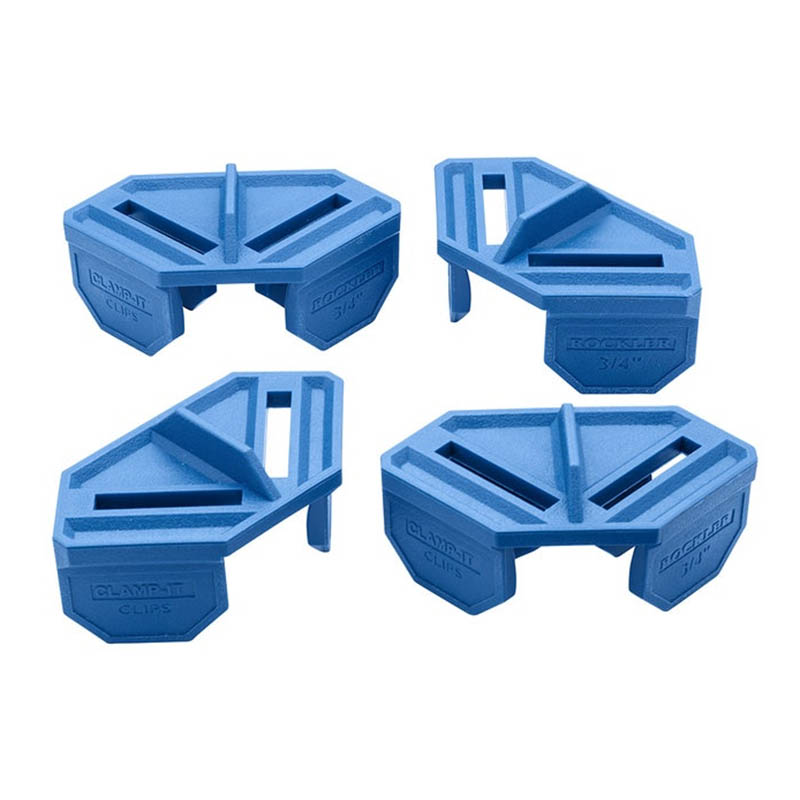

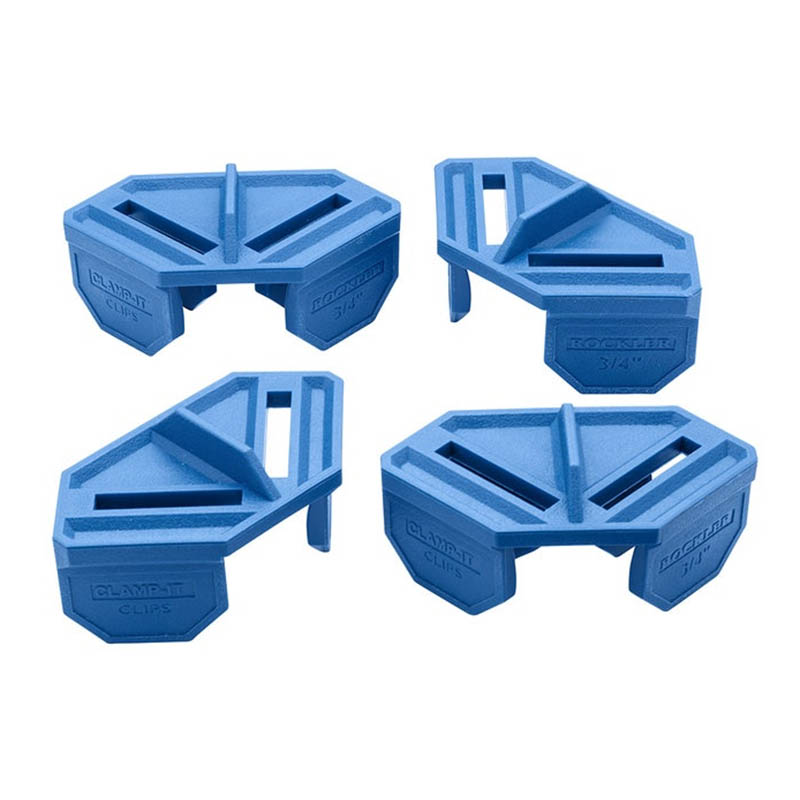

Plastic Clamps Molding

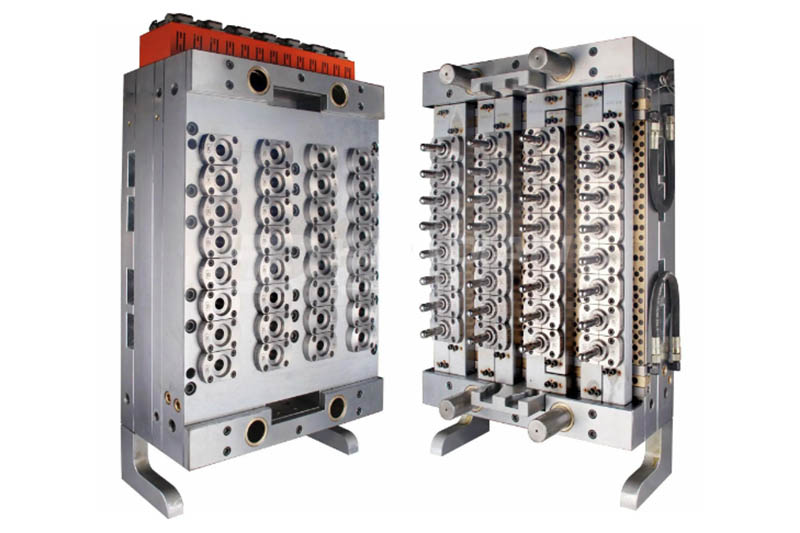

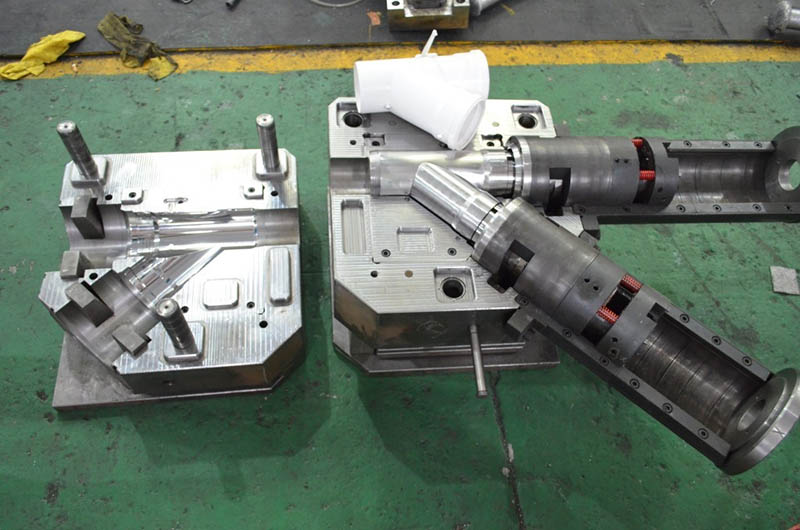

As the professional manufacturer, we would like to provide you Plastic Clamps Molding. Ningbo P&M specializes in the manufacturing of Plastic clamps and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic clamp solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic clamps sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic clamps. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.

Send Inquiry

We are a professional China Plastic Clamps Molding manufacturer and supplier. Plastic clamps are versatile fastening devices used in various industries for securing, holding, or attaching objects together. These clamps come in a wide range of types and designs, each tailored to specific applications and requirements. Plastic clamps provide a lightweight, durable, and cost-effective solution for holding items in place or joining components. Let's explore the types, applications, and significance of plastic clamps, followed by an overview of Ningbo P&M's expertise in manufacturing plastic clamps through injection molding and the advantages they offer in this specialized field.

Types of Plastic Clamps:

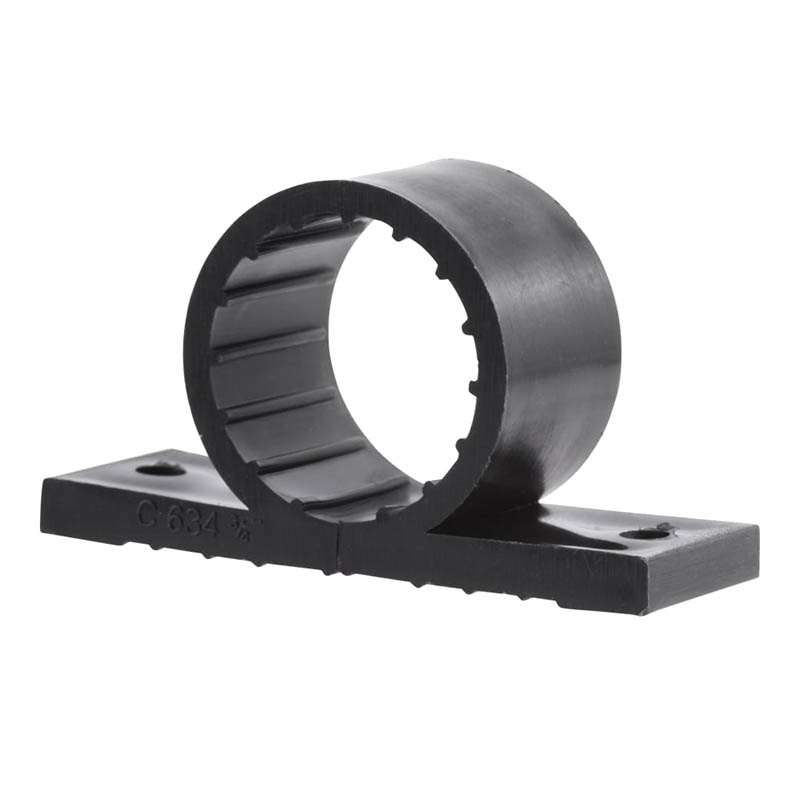

1.Cable Clamps: Used for securing cables or wires in place to prevent tangling or damage.

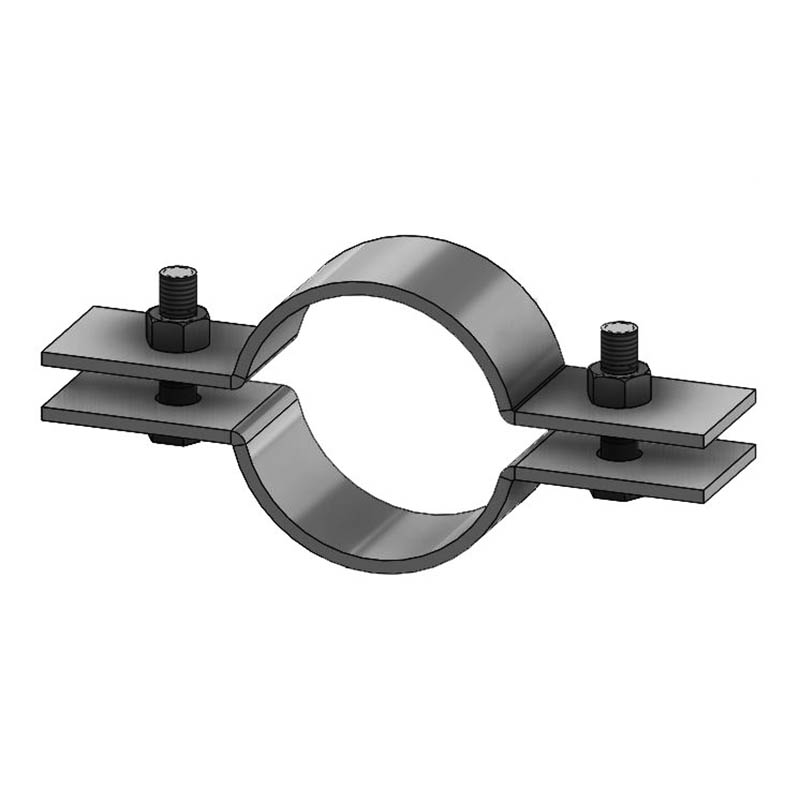

2.Pipe Clamps: Designed to hold pipes securely in position within a system.

3.Hose Clamps: Used to secure hoses onto fittings to prevent leaks or disconnections.

4.Spring Clamps: Feature a spring mechanism for quick and easy application.

5.Toggle Clamps: Provide a quick-release mechanism for fastening or releasing objects.

6.One-Piece Clamps: Consist of a single piece for easy installation and removal.

7.Adjustable Clamps: Allow for varying sizes of objects to be clamped securely.

8.C-Clamps: Shaped like the letter "C" and used for holding objects in place during work.

9.Clips and Grips: Offer quick and temporary fastening solutions for various applications.

10.Mounting Clamps: Used for attaching objects to surfaces or structures securely.

Applications of Plastic Clamps:

•Automotive Industry: Plastic clamps are used for securing wiring harnesses, hoses, and other components in vehicles.

•Electronics: Cable clamps are essential for organizing and securing cables in electronic devices and systems.

•Plumbing Systems: Pipe and hose clamps are utilized in plumbing installations to secure pipes and hoses in place.

•HVAC Systems: Clamps are used in heating, ventilation, and air conditioning systems to secure ductwork and components.

•Manufacturing: Plastic clamps find applications in manufacturing processes for holding workpieces or parts in place.

•DIY and Home Improvement: Clamps are used in woodworking, metalworking, and various DIY projects for holding materials together.

•Medical Devices: Plastic clamps are used in medical equipment and devices for securing tubes and cables.

•Agriculture: Hose clamps are used in irrigation systems and agricultural machinery for securing hoses and pipes.

•Marine Industry: Plastic clamps are used in marine applications for securing cables, hoses, and equipment on boats and ships.

•Construction: Clamps find applications in construction projects for holding materials in place during assembly or installation.

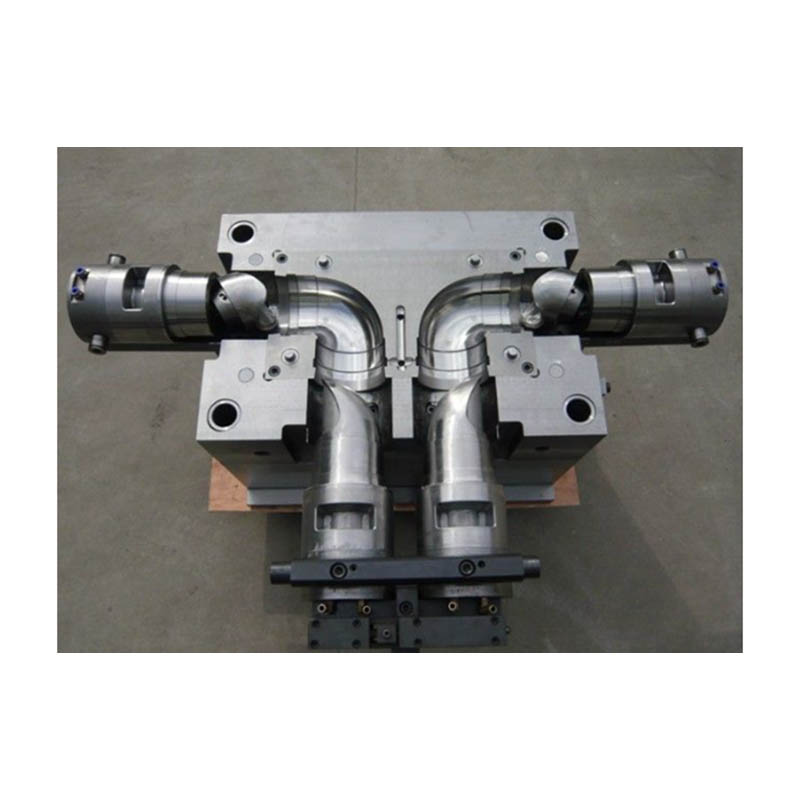

Ningbo P&M's Expertise in Injection Molding of Plastic Clamps:

Ningbo P&M is a reputable manufacturer known for its precision engineering and dedication to quality in producing plastic clamps through injection molding. Their expertise and advantages in this field demonstrate their ability to deliver high-quality and customized solutions that meet the specific needs of diverse industries.

Advantages in Plastic Clamps Manufacturing:

1.Customization Capabilities: Ningbo P&M offers a wide range of customization options for plastic clamps, allowing for tailored designs, sizes, and specifications to meet specific application requirements effectively.

2.Advanced Injection Molding Technology: By utilizing advanced injection molding technology, Ningbo P&M ensures the production of plastic clamps with precise dimensions, consistent quality, and reliable performance.

3.Quality Assurance: Stringent quality control measures are implemented throughout the manufacturing process to ensure that each plastic clamp meets industry standards for durability, strength, and functionality.

4.Efficient Production Processes: Through optimized workflows and efficient manufacturing practices, Ningbo P&M minimizes lead times and ensures timely delivery of plastic clamps without compromising on quality or performance.

5.Innovative Design Solutions: With a team of experienced engineers and designers, Ningbo P&M develops innovative design solutions for plastic clamps, enhancing functionality, ease of use, and durability in various applications.

6.Cost-Effective Manufacturing: By implementing cost-effective production practices and resource management strategies, Ningbo P&M offers competitive pricing for plastic clamps without sacrificing quality, providing value to customers across industries.

In conclusion, Ningbo P&M's proficiency in injection molding and manufacturing plastic clamps showcases their expertise, innovation, and commitment to quality in producing essential components for diverse industries. Their advantages in producing plastic clamps highlight their leadership in the industry and their capability to deliver customized solutions that meet the stringent requirements of various applications.

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

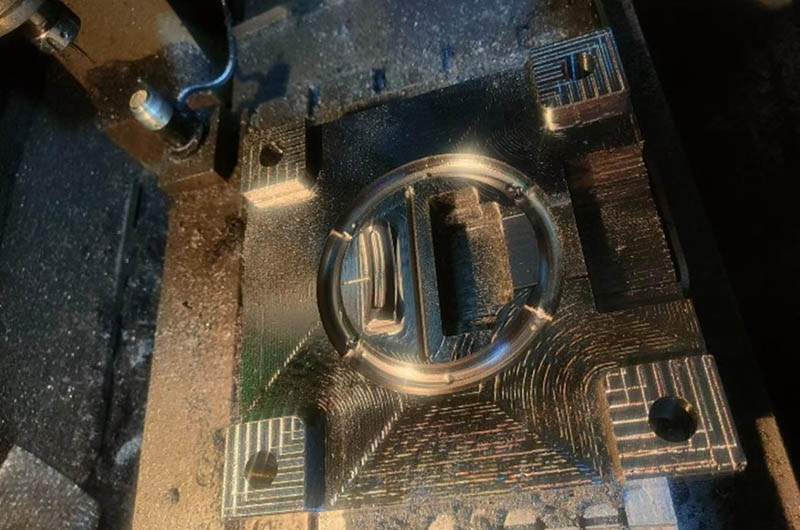

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

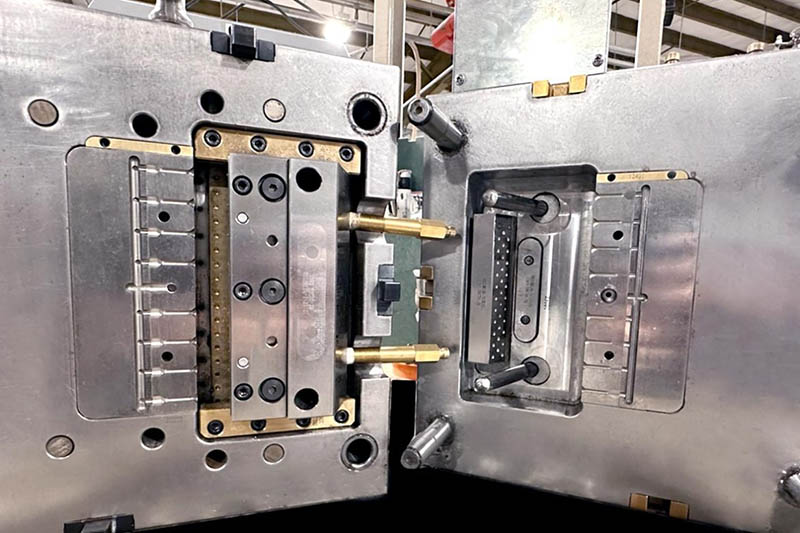

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

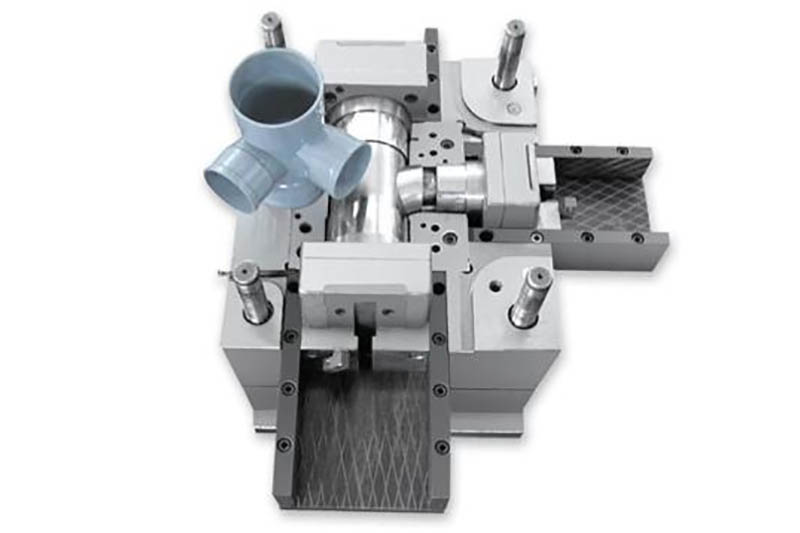

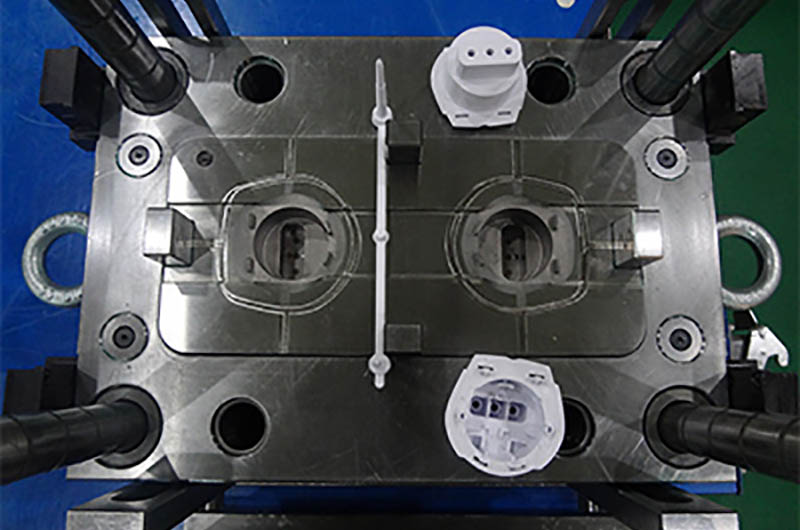

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

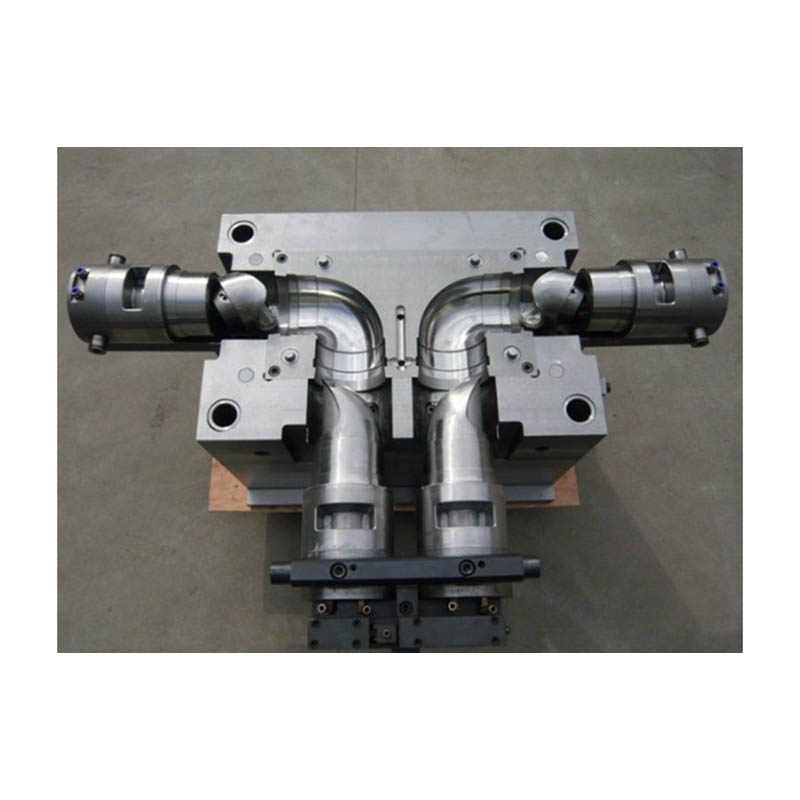

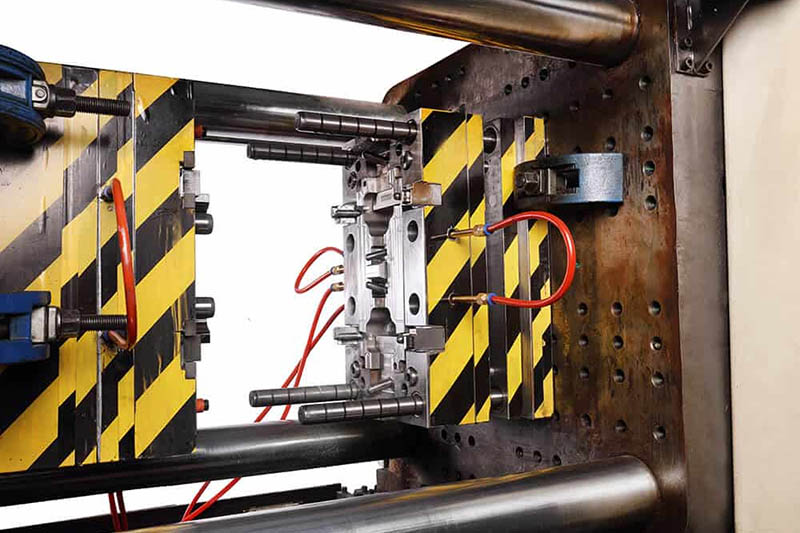

Plastic Injection Mould making

1.Samples/Drawing &Requirement from you.

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3. Material Purchase:Steel cutting and Mould base tooling.

4. Assembling.

5. Inspection of mould : following and controlling the tooling processing.

6. Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7. Your instruction &confirmation for shipment. 8.Ready made mould before packing. 9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Mold base :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Transaction process:

Mold testing:

Once the mold is complete, I do a mold test. It usually takes about 3-5 days to complete. We need to assemble the mold, adjust the pressure data of the machine, and try production. We need to check whether there are problems during the normal production of the mold and make modifications.

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

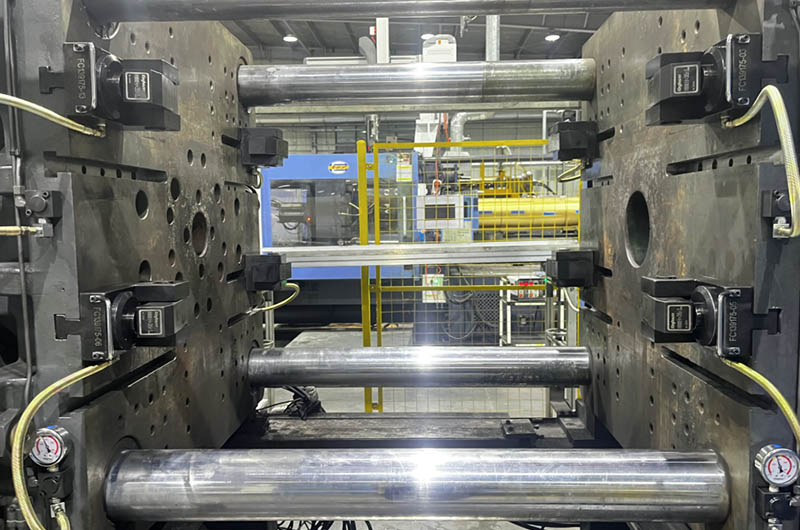

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 15 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We are plastic iniection mold maker, we have High-quality mold manufacturing, our main feature is Custom injection mold, we focus on Plastic mold design and manufacturing. We provide Custom injection mold service.We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.