- Core Customization Service

- Health Care

- Electronic Appliances and Instruments

- Maternal and Child Supplies Molds

- Recreational Sports

- Home Furnishing Art

- Auto Accessories

- Transportation and Warehousing

- Lighting Fixtures

- Construction Equipment

- Packaging Product

- Educational & Laboratories

- Clothing Luggage Accessories

- Care and Cleaning Products

- Agriculture & Forestry

- Mechanical Equipment

- Pet Supplies

- Kitchenware

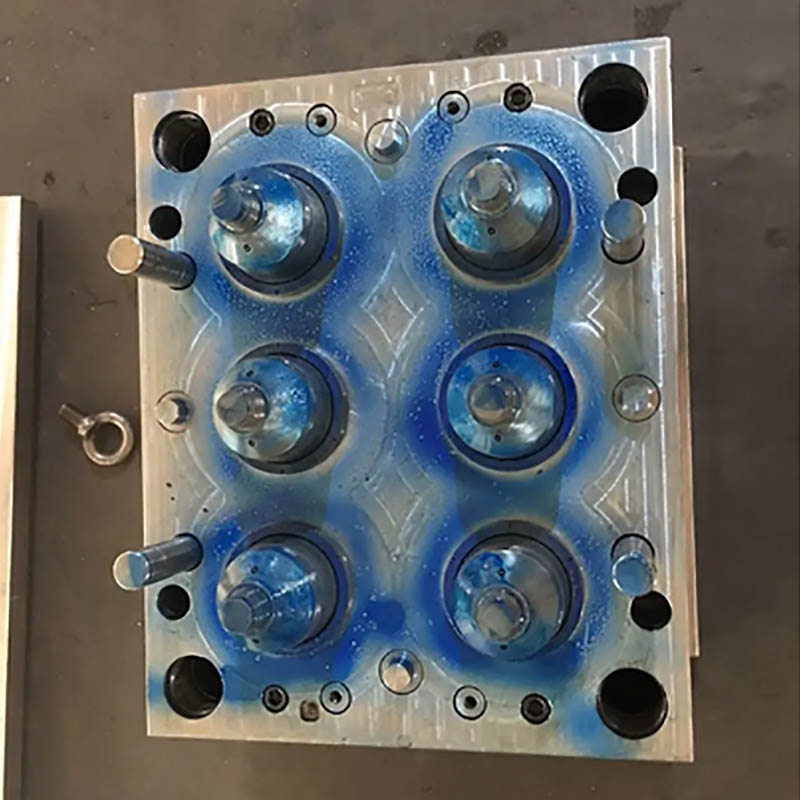

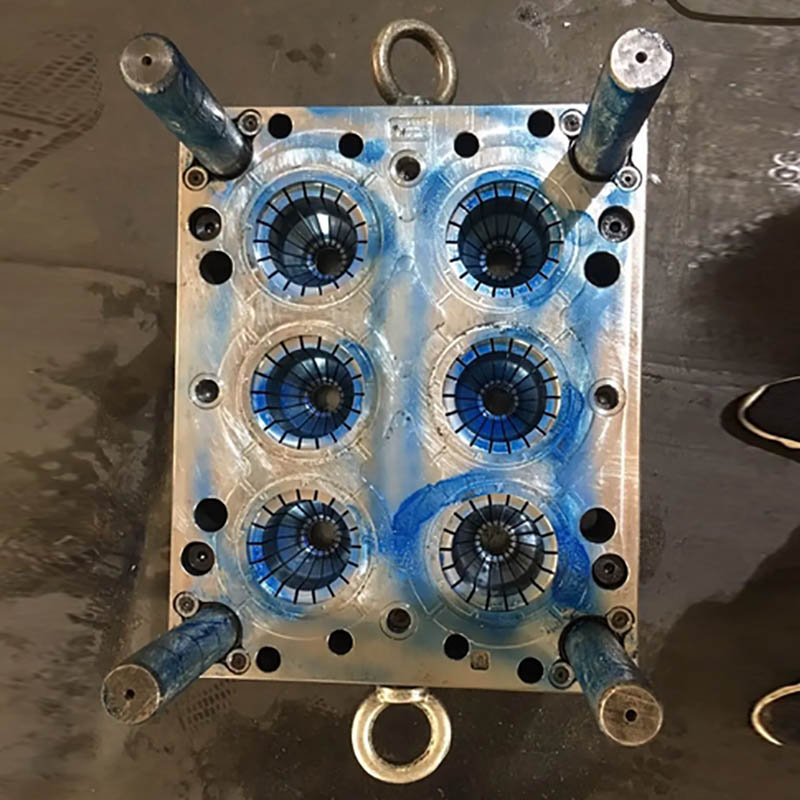

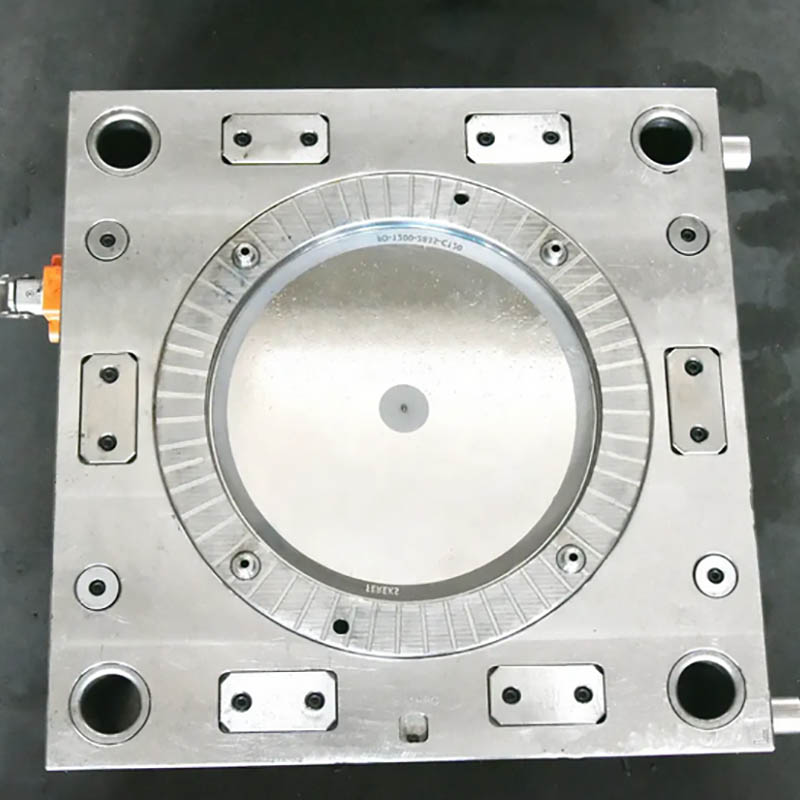

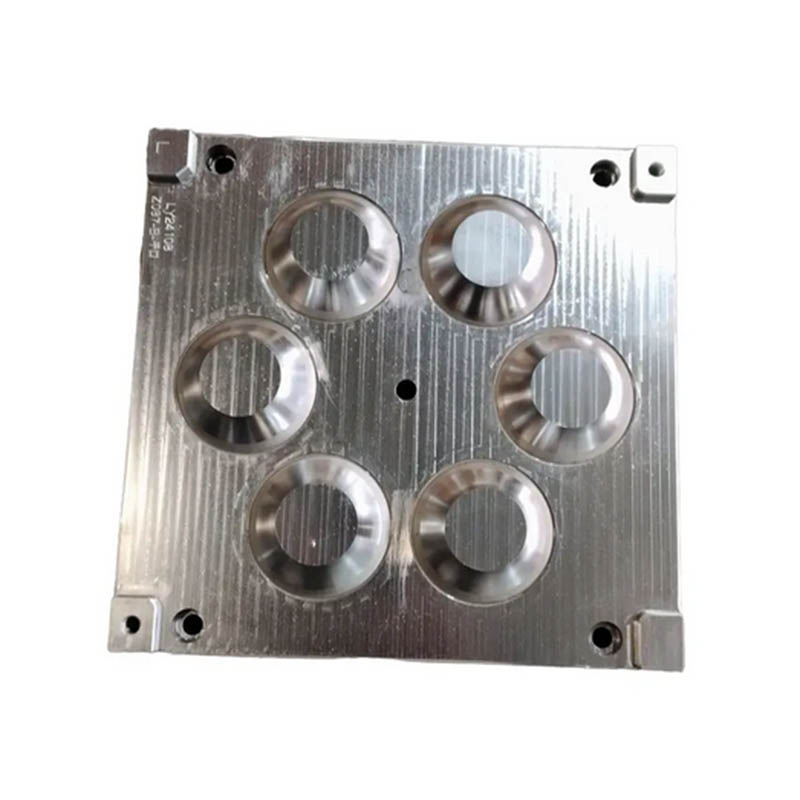

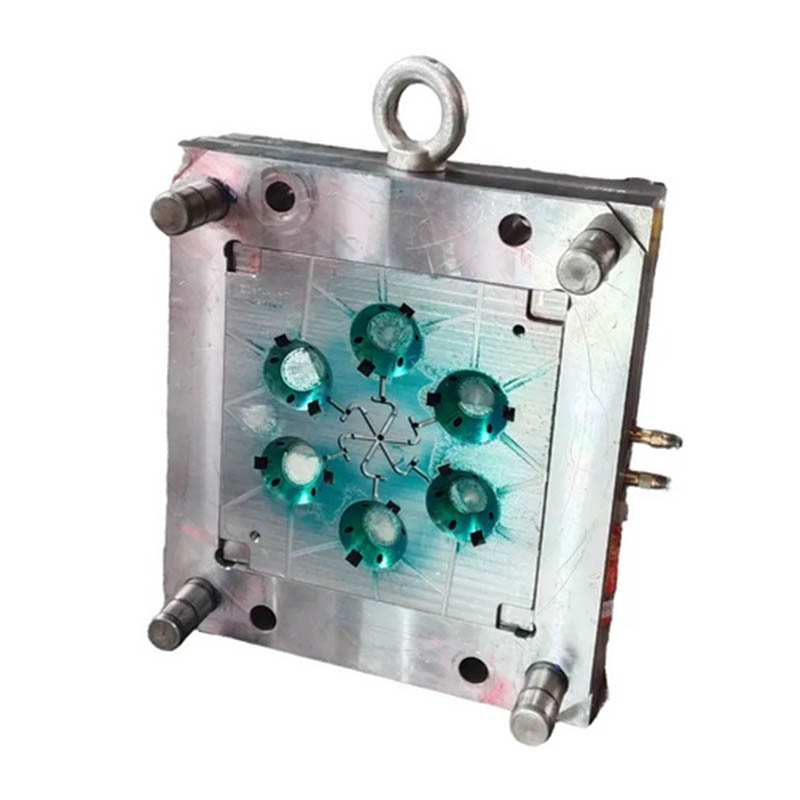

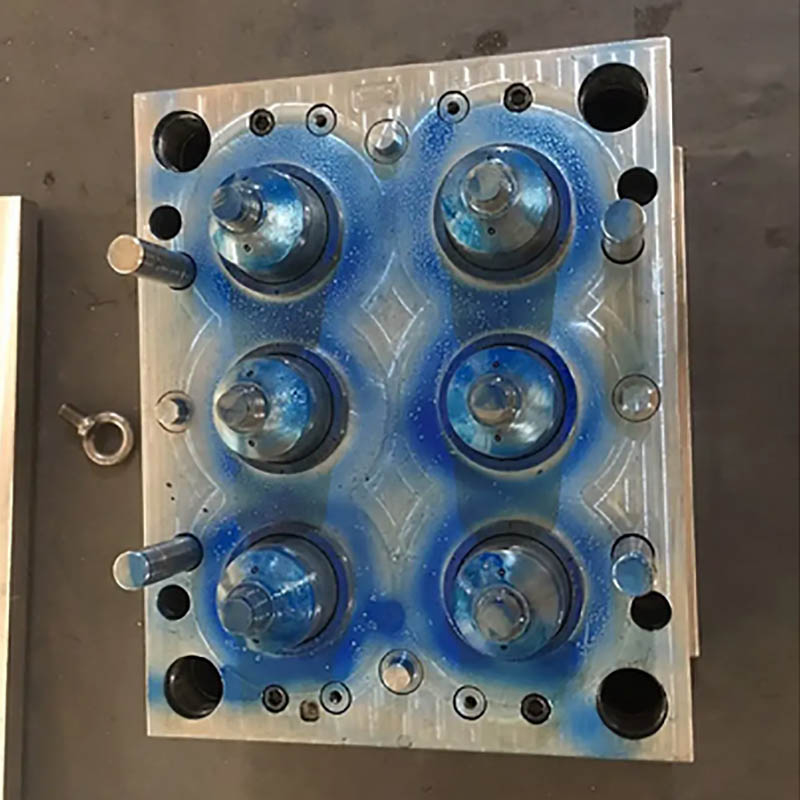

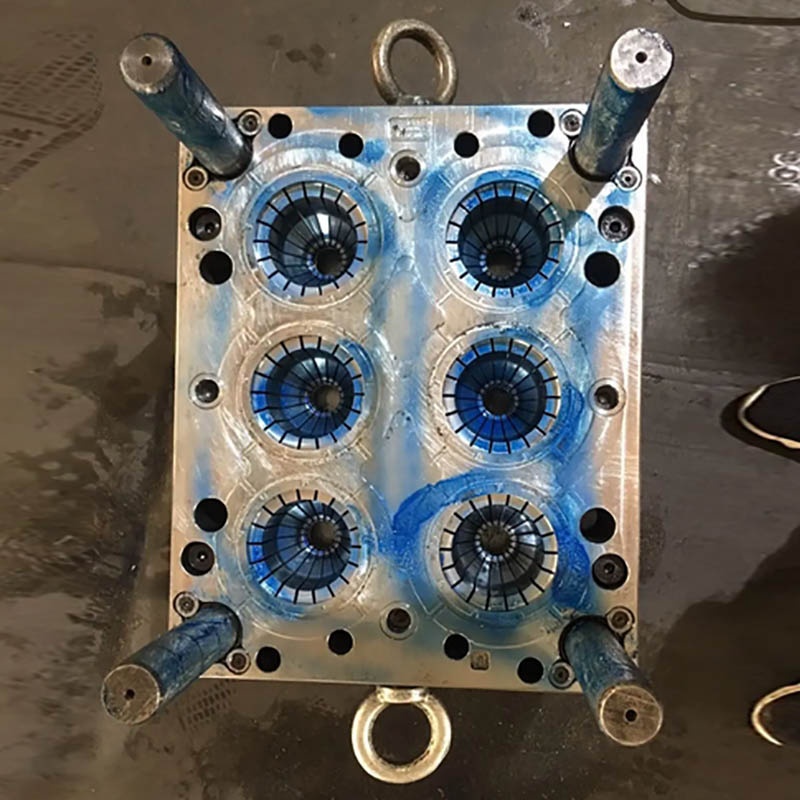

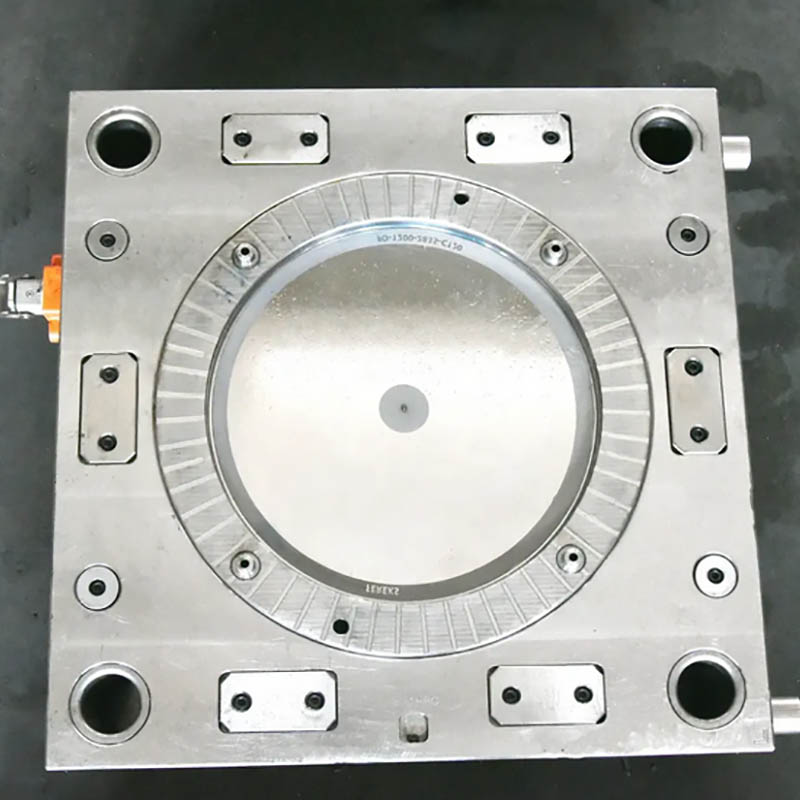

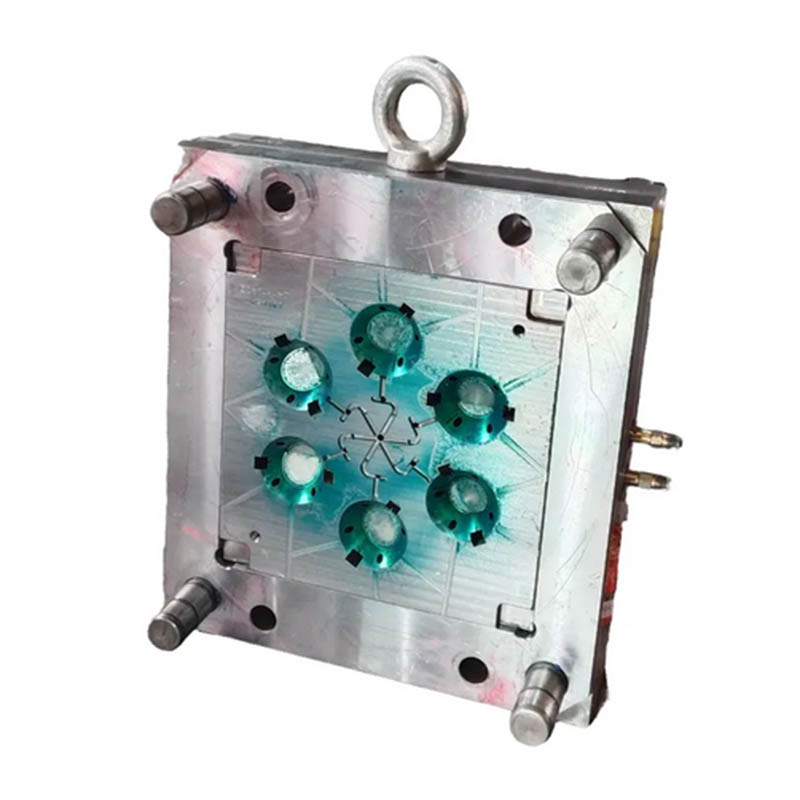

LED Downlight Molding

For LED downlight molding, Our company is a high-tech enterprise specializing in the research and development, design, production, and sales of LED downlight moulding. With years of industry experience, we are committed to providing efficient, energy-saving, high-quality, and durable LED lighting products. Our LED downlight moulding are widely used in commercial lighting, home lighting, hotel lighting, office spaces, exhibition halls, supermarkets, etc., and are highly trusted by domestic and foreign customers.

Send Inquiry

Our advantages

✅ Rich industry experience: With years of deep cultivation in the LED downlight moulding, we have accumulated mature R&D and production experience.

✅ Professional R&D team: With engineers in the fields of optical design, power drive, and heat management, we continuously innovate and optimize our products.

✅ High quality LED chips: using internationally renowned brand LED chips (such as Cree, Samsung, Osram, Philips) to ensure high brightness, high finger count, and long lifespan.

✅ Efficient and stable driving power supply: independently developed constant current drive, supporting dimming and intelligent control to enhance product stability.

✅ Excellent heat dissipation design: using aluminum alloy heat sink and nano heat dissipation coating, effectively reducing light decay and extending service life.

✅ Strict quality control: All products have passed aging testing, light efficiency testing, EMC testing, and comply with international certification standards such as CE, RoHS, FCC, UL, etc.

Success cases

📌 Five star hotel LED downlight moulding project

📌 Large shopping mall&supermarket LED downlight moulding project

📌 LED downlight moulding for office buildings and exhibition halls

📌 Smart Home LED downlight moulding Customization Project

Collaboration and Customization

We support OEM/ODM customization and provide a one-stop LED downlight moulding solution from product design, mold development, manufacturing to brand outsourcing. Whether it's bulk procurement or customized to specific needs, we can provide you with high-quality and cost-effective LED downlight moulding products.

Welcome to consult and cooperate!

If you are looking for a professional LED downlight moulding manufacturer, please contact us and we will provide you with high-quality products and professional technical support!

LED downlight molding

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and LED downlight moulding. We have our own engineer and factory, so that we can customer any plastic and metal products for our customer.

The production of LED downlight moulding involves multiple stages, from design and development to final packaging and delivery, each step needs to be strictly controlled to ensure product quality and performance.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

Contact us

If you are looking for a high-quality LED downlight moulding manufacturer, please feel free to contact us. We will wholeheartedly provide you with professional, efficient, and reliable mold solutions!

LED downlight moulding

|

Pls provide |

2D, 3D, samples, or the size of the multi-angle pictures |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Mould precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main technology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Quality system |

ISO9001:2008 |

|

Establish time |

20days |

|

Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcase mould zhe jiang |

1. Requirement analysis and design

Customer requirement confirmation: Determine the size, appearance, material, function, and other requirements for LED downlight moulding.

Product design: Use CAD (such as SolidWorks, UG, Pro/E) for product appearance and structural design.

Manufacturability Analysis (DFM): Evaluate whether product design is suitable for mold manufacturing, optimize structure to avoid production defects.

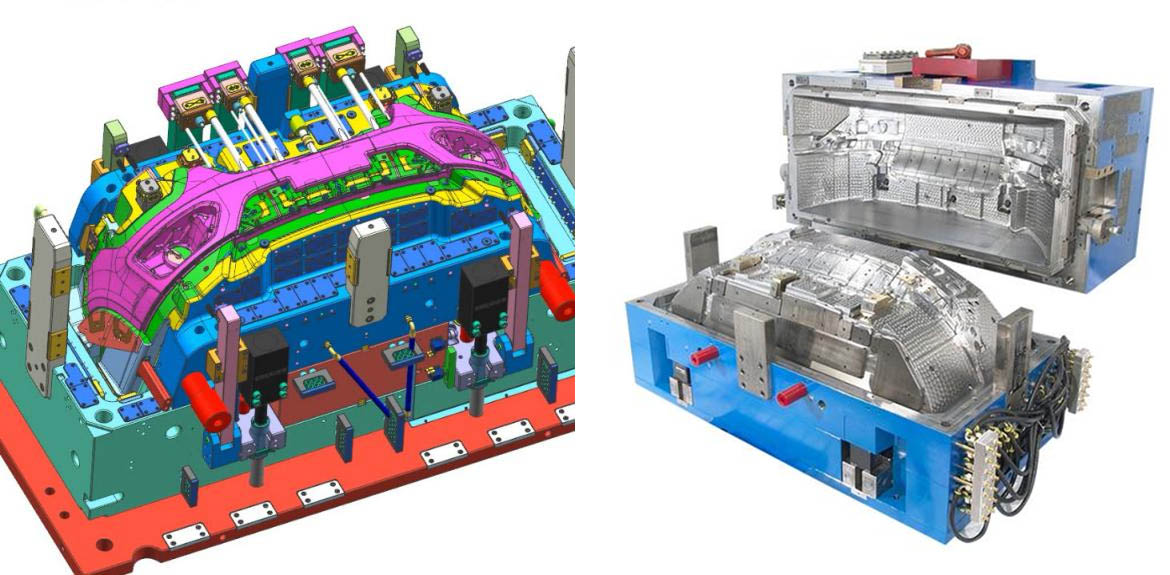

2. Mold design

Mold scheme formulation: Determine the type of mold (such as hot runner mold, cold runner mold), gate position, parting surface, ejection method, etc.

Mold 3D design: Detailed design using software such as UG, Moldflow, AutoCAD, etc., and flow analysis to optimize injection performance.

Material selection: Choose appropriate mold steel (such as P20, 718H, S136, NAK80) to ensure mold durability and molding quality.

We focus on the research and manufacturing of plastic molds for LED downlight moulding, with years of industry experience and advanced production equipment. With a professional design team, precision machining technology, and strict quality control system, we provide customers with efficient and durable mold solutions, ensuring stable product quality, high production efficiency, and controllable costs.

3.Our advantages:

✅ Rich experience - years of mold manufacturing experience, familiar with various LED downlight moulding and forming processes.

✅ Precision design - optimized design using UG, Moldflow, and AutoCAD to ensure superior mold performance.

✅ High end equipment - equipped with CNC machining centers, electric discharge machines, wire cutting and other precision machining equipment to ensure mold accuracy.

✅ Strict quality control - implementing full process quality inspection from material selection, processing, mold testing to delivery.

✅ Fast delivery - efficient production process ensures timely delivery of molds, helping customers seize market opportunities.

✅ Improve after-sales service - provide mold maintenance guidance and technical support to ensure customers can produce with peace of mind.

We are committed to providing customers with high-quality, high-precision, and durable plastic molds for LED downlight moulding, helping them enhance their product competitiveness. If you have mold customization needs, please feel free to contact us!

Injection Mould making

1. Samples/drawings and requirements from you.

2. Mold design: After you place an order, we will communicate with you and exchange opinions.

3. Material procurement: steel cutting and mold basic tools.

4. Assembly.

5. Mold inspection: Track and control mold processing.

6. Mold testing: We will notify you of the date. Then the sample inspection report and injection parameters will be sent to you together with the sample!

7. Your shipping instructions and confirmation.

8. Make the mold before packaging.

9. We provide various plastic injection molds, blow molds, silicone molds, and die-casting mold services.

Plastic molding specifications

1. Professional manufacturing, design and production of injection molds and stamping mold quality control

2. Have rich experience in exporting injection molds and stamping molds

3. Design molds at reasonable prices

4. Cavity: single cavity or as per your requirement

5. Treatment: S45C pretreatment >25Hrc, and nitriding

6. Mold steel: section steel, core steel, slider steel: P20, 2738, 2136 optional

7. Standard: Democratic, Husky, Available

8. Hot runner: according to your needs

9. Lifespan:>300,000 times

10. Packing: plywood box, coated with anti-rust paint

Transaction process

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

We are plastic iniection mold maker, we have High-quality mold manufacturing, our main feature is Custom injection mold, we focus on Plastic mold design and manufacturing. We provide Custom injection mold service.We always adhere to the principle of quality first and time first. While providing customers with the best quality products, we try to improve production efficiency and shorten production time. We are proud to tell every customer that our company has not lost a single customer since its inception. If there is a problem with the product, we will actively seek solutions and take responsibility to the end. Please choose us and let us become a long-term cooperation partner.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product, Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.