Focus on advancements in mold materials and their impact

2025-01-20

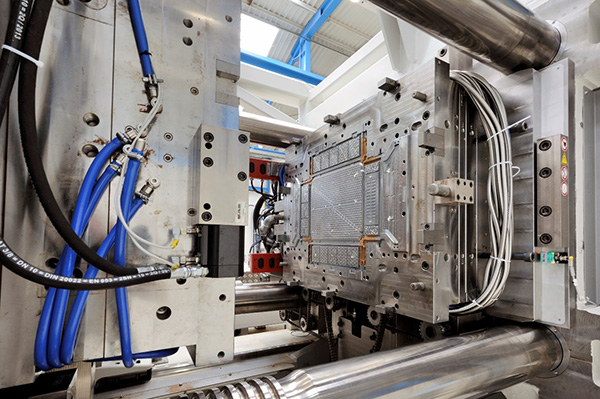

Advancements in mold materials are reshaping the injection molding industry, revolutionizing production processes, enhancing product quality, and driving efficiency. The continuous innovation in mold materials is crucial for meeting the increasing demands of modern manufacturing. Here are some recent developments and their impact on the injection molding industry:

1. High-Performance Tool Steels

High-performance tool steels, such as H13, P20, and S7, have long been staples in injection molding due to their excellent wear resistance, toughness, and thermal conductivity. Recent advancements in metallurgy have led to the development of even more durable and heat-resistant tool steels, allowing for extended mold life and improved part quality.

2. Advanced Ceramics

Ceramic mold materials, like alumina and zirconia, are gaining popularity in injection molding applications due to their exceptional hardness, wear resistance, and thermal stability. These materials enable the production of high-precision components with intricate details, making them ideal for industries requiring tight tolerances and complex geometries.

3. Metal Matrix Composites

Metal matrix composites (MMCs), which combine metal matrices with reinforcing materials like ceramics or carbon fibers, offer superior strength, stiffness, and thermal properties compared to traditional metals. In injection molding, MMC molds provide enhanced durability, thermal management, and dimensional stability, resulting in improved part quality and productivity.

4. Additive Manufacturing

The rise of additive manufacturing, particularly in 3D printing, has opened up new possibilities for mold production. Additive manufacturing allows for the rapid prototyping and fabrication of complex mold designs with intricate features that would be challenging or impossible to achieve using traditional methods. This flexibility in mold design enhances product customization and accelerates time-to-market.

5. Nanostructured Materials

Nanostructured materials, such as nano-coated steels and alloys, exhibit unique properties like increased hardness, reduced friction, and enhanced corrosion resistance. By incorporating nanotechnology into mold materials, manufacturers can improve mold durability, reduce maintenance requirements, and enhance part quality, ultimately leading to more efficient production processes.

Impact on the Industry:

· Enhanced Durability: Advanced mold materials offer increased wear resistance and longevity, reducing downtime and maintenance costs.

· Improved Part Quality: Superior thermal properties and dimensional stability result in higher precision and consistency in molded parts.

· Increased Efficiency: Enhanced material properties contribute to faster cycle times and improved productivity.

· Innovation in Design: The versatility of new materials allows for the creation of complex mold designs, expanding design possibilities for manufacturers.

In conclusion, the continuous advancements in mold materials are driving significant improvements in the injection molding industry, enabling manufacturers to produce high-quality parts more efficiently and cost-effectively. By leveraging these innovative materials, companies can stay competitive in an ever-evolving market and meet the demands of an increasingly diverse range of products and applications.