Rotomolding has gained popularity in various industries due to its unique advantages. According to a report by Smithers Pira, the rotomolding market is projected to grow at a CAGR of 5.2% between 2023 and 2028. This growth highlights the increasing demand for high-quality, durable products made through this process.

As industry expert Jessica Hartman states, "Rotomolding offers unmatched flexibility and design potential." This method allows for the creation of complex shapes without the need for expensive molds. However, achieving consistency and quality can be challenging. Some manufacturers still struggle with defects that impact overall efficiency.

While rotomolding enables companies to produce innovative solutions, careful planning and execution are essential. Understanding material selection, wall thickness, and cooling time are critical for success. Mistakes in these areas can lead to wasted resources and increased costs. By recognizing these challenges, businesses can better harness the potential of rotomolding for their projects.

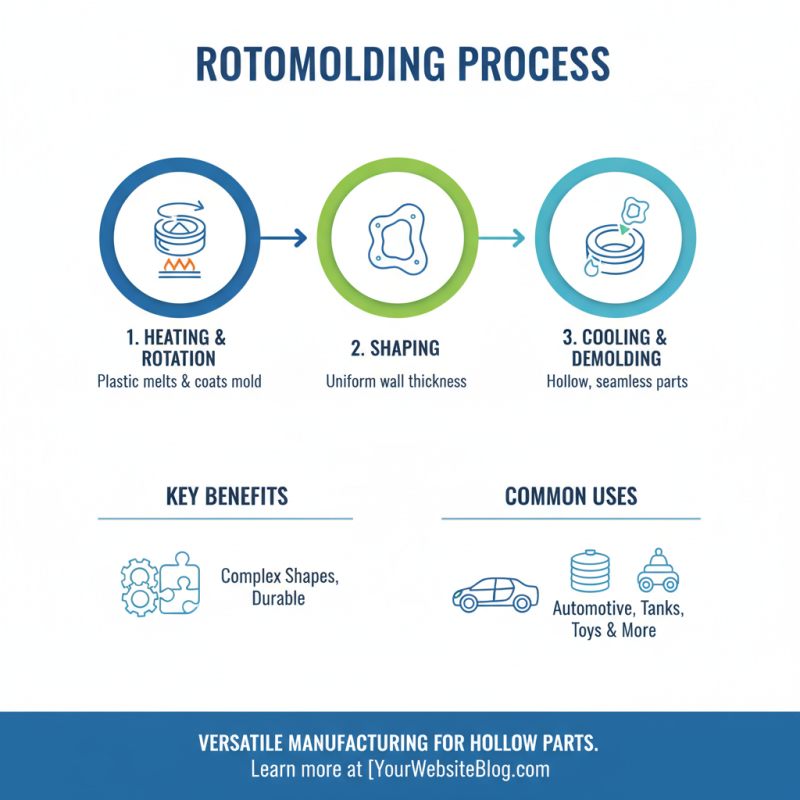

Rotomolding, or rotational molding, is a fascinating manufacturing technique. It is primarily used to create hollow plastic parts. This method uses a heated mold and plastic powder. As the mold rotates, the powder melts and coats the interior. The end result is a strong, seamless product.

One of the key advantages of rotomolding is design flexibility. It's possible to produce complex shapes with varying wall thicknesses. However, this doesn’t come without challenges. The cooling cycle can be inconsistent, which may lead to defects. Understanding temperature control is critical to achieving high-quality results.

Another consideration is the material choice. Various plastics like polyethylene and nylon can be used. Each material has unique properties that affect durability and finish. Experimenting with different formulations is vital but can be time-consuming. The learning curve can be steep, requiring experimentation to refine processes. This ongoing refinement is where many projects fall short. Balancing creativity and practicality is essential for success.

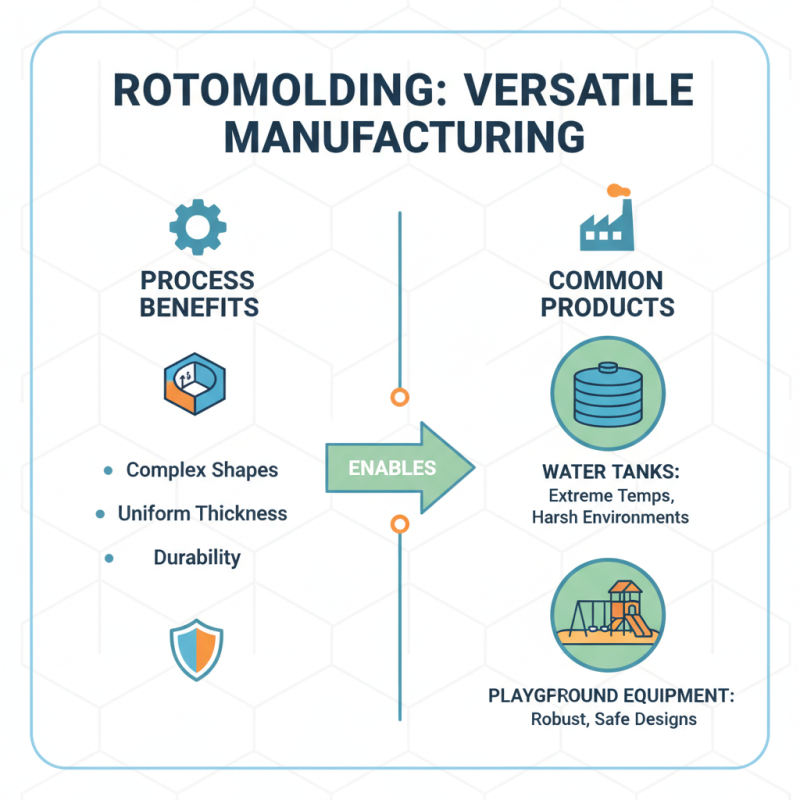

Rotomolding is an innovative manufacturing process with unique advantages. One key benefit is its ability to create complex shapes. The process allows for even wall thickness, which enhances durability. This feature is vital for products that need to withstand harsh conditions. Additionally, rotomolding accommodates a variety of materials, including plastics and composites.

When considering rotomolding for your next project, think about the design. Keep it simple at first. Complex designs can lead to unexpected challenges. Test small prototypes before scaling up. This approach saves time and resources. It also provides valuable insights into potential issues.

Another advantage of rotomolding is cost-effectiveness. The initial investment can be lower than other manufacturing methods. However, production times can be longer. Be prepared for this aspect. Efficient scheduling can mitigate delays. Lastly, explore custom color options. They can enhance visual appeal but may require extra planning. Embrace the learning curve, as it can lead to remarkable outcomes.

Rotomolding is a versatile manufacturing process that creates hollow parts. It involves rotating a mold while heating it, allowing the plastic to coat the interior surface. This method is great for creating complex shapes with uniform wall thickness. It’s widely used in various industries, from automotive to consumer goods.

The step-by-step rotomolding process starts with mold preparation. Clean your mold thoroughly. Any residue can affect the quality of the final product. After preparing the mold, add the right amount of powdered plastic. The amount depends on the desired thickness of the finished part.

Next, heat the mold. This phase requires close attention. Monitor the temperature to avoid overheating. Overheating can lead to imperfections. After reaching the desired heat level, rotate the mold. This continuous movement helps distribute the plastic evenly. Once cooled, remove the part and inspect it. Look for any flaws or uneven spots that may have developed.

Tips: Always double-check measurements before starting. A small error can lead to waste. Also, keep an eye on your mold during heating. If it warps, your product will be affected. Don’t rush the cooling process. Patience is key to achieving the best results.

When designing rotomolded products, several key factors come into play. Material choice is critical. Polyethylene is often favored due to its durability. A 2021 industry report highlighted that over 70% of rotomolded objects utilize polyethylene, thanks to its versatile properties. Designers must also consider wall thickness. Thicker walls offer strength but increase weight. The right balance is essential for functionality.

Another vital aspect is the design's complexity. Rotomolding allows for intricate shapes but may complicate the manufacturing process. According to surveys, 30% of designers reported challenges in achieving details like grooves or recesses. This can lead to additional costs and delays. The production cycle might take longer than expected, requiring careful planning.

Lastly, anticipate challenges like shrinkage or distortion. Proper cooling time is necessary to avoid these issues. A study revealed that improperly cooled items could lead to rejection rates of up to 15%. Addressing these concerns in your design phase can ensure a smoother production process.

Rotomolding is a versatile manufacturing process. It is widely used across various industries. It allows for creating complex shapes with uniform thickness. This makes it ideal for products like storage tanks and playground equipment. For instance, water tanks benefit from rotomolding's durability. They can withstand extreme temperatures and harsh environments.

In the automotive sector, rotomolding is gaining traction. Companies are making fuel tanks and components with this method. It reduces weight while maintaining strength. However, challenges arise in achieving the desired finish. Some parts may not meet visual standards. This requires careful planning and quality control.

The consumer goods sector utilizes rotomolding too. Items like coolers and large containers are common examples. However, the process can be wasteful. Scrap material can accumulate during production. This aspect raises concerns about sustainability. Improving recycling methods could enhance the rotomolding industry's eco-friendliness. Addressing such issues is crucial for future advancements.