Plastic molding is a pivotal process in various industries, playing a crucial role in the design and manufacture of countless products. According to the Harvard Business Review, the global plastic molding market is expected to reach $500 billion by 2026, demonstrating the remarkable growth and demand for efficient manufacturing techniques. As businesses strive to streamline production while maintaining quality, mastering plastic molding techniques has become essential.

Plastic molding is a pivotal process in various industries, playing a crucial role in the design and manufacture of countless products. According to the Harvard Business Review, the global plastic molding market is expected to reach $500 billion by 2026, demonstrating the remarkable growth and demand for efficient manufacturing techniques. As businesses strive to streamline production while maintaining quality, mastering plastic molding techniques has become essential.

This guide delves into the fundamental aspects of plastic molding, offering valuable tips and best practices designed to optimize production processes. Whether you're a seasoned professional or a newcomer to the industry, understanding the intricacies of plastic molding will empower you to enhance your manufacturing capabilities, reduce waste, and meet the evolving demands of consumers.

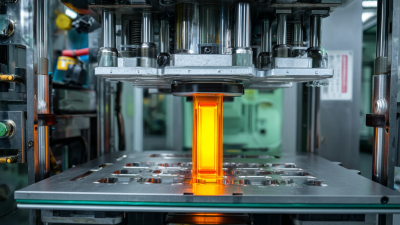

In the rapidly advancing landscape of plastic molding, understanding key techniques is essential for manufacturers aiming to enhance production efficiency and product quality. Injection molding, a predominant method in the industry, is projected to significantly grow, driven by applications across various sectors including consumer products and medical devices. Reports indicate that the plastic granules market is set to expand considerably, reflecting the increased necessity for advanced materials in the production of orthopedic implants and dental devices, which are critical in addressing the rising incidence of orthopedic diseases.

Furthermore, Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) injection molding technologies are gaining traction. As of 2023, the LIM and LSR injection machine market is valued at approximately $148.41 million, with forecasts suggesting a rise to $159.5 million by 2024. This growth highlights the demand for versatile molding techniques that cater to complex and high-performance applications, such as automotive components and medical devices. Manufacturers must stay informed about these evolving technologies and market trends to maintain their competitive edge and ensure they meet the increasing demands of various industries.

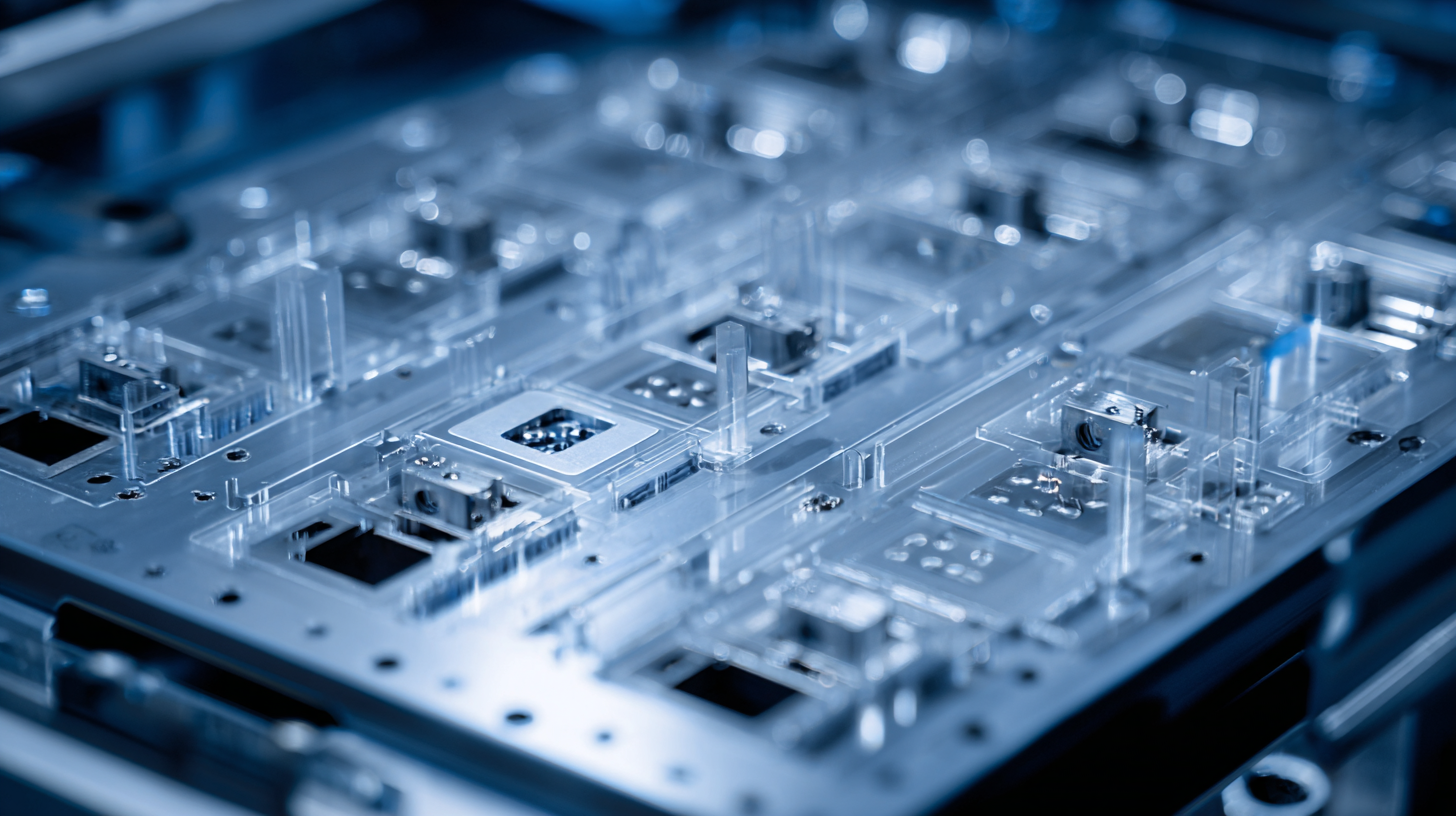

When undertaking plastic molding projects, several key factors can significantly influence success, particularly in the face of evolving industry demands. One of the top considerations is the capability of the molding equipment. As highlighted by a recent project in the industry, an increase in press size has opened new opportunities for molders, allowing for the production of larger parts with enhanced detail and precision. According to industry reports, companies that invest in advanced machinery can boost efficiency and reduce defect rates by up to 30%, thus directly impacting their bottom line.

Another critical factor is material selection. The choice of resin can affect the molding process, end product performance, and overall cost. For instance, using high-performance polymers may present initial financial challenges, but the long-term benefits often justify the investment, especially in applications demanding high durability or temperature resistance. Data suggests that more than 60% of molding failures can be traced back to inappropriate material use, underscoring the importance of thorough material analysis and testing prior to project initiation.

Additionally, mold design plays a pivotal role in project success. An optimized mold can enhance cooling efficiency and minimize cycle times, resulting in significant production gains. Reports indicate that effective mold design can improve cycle times by as much as 50%, thus providing a competitive edge in time-to-market strategies. By focusing on these critical elements—equipment capability, material choice, and mold design—manufacturers can elevate their plastic molding projects to new levels of effectiveness.

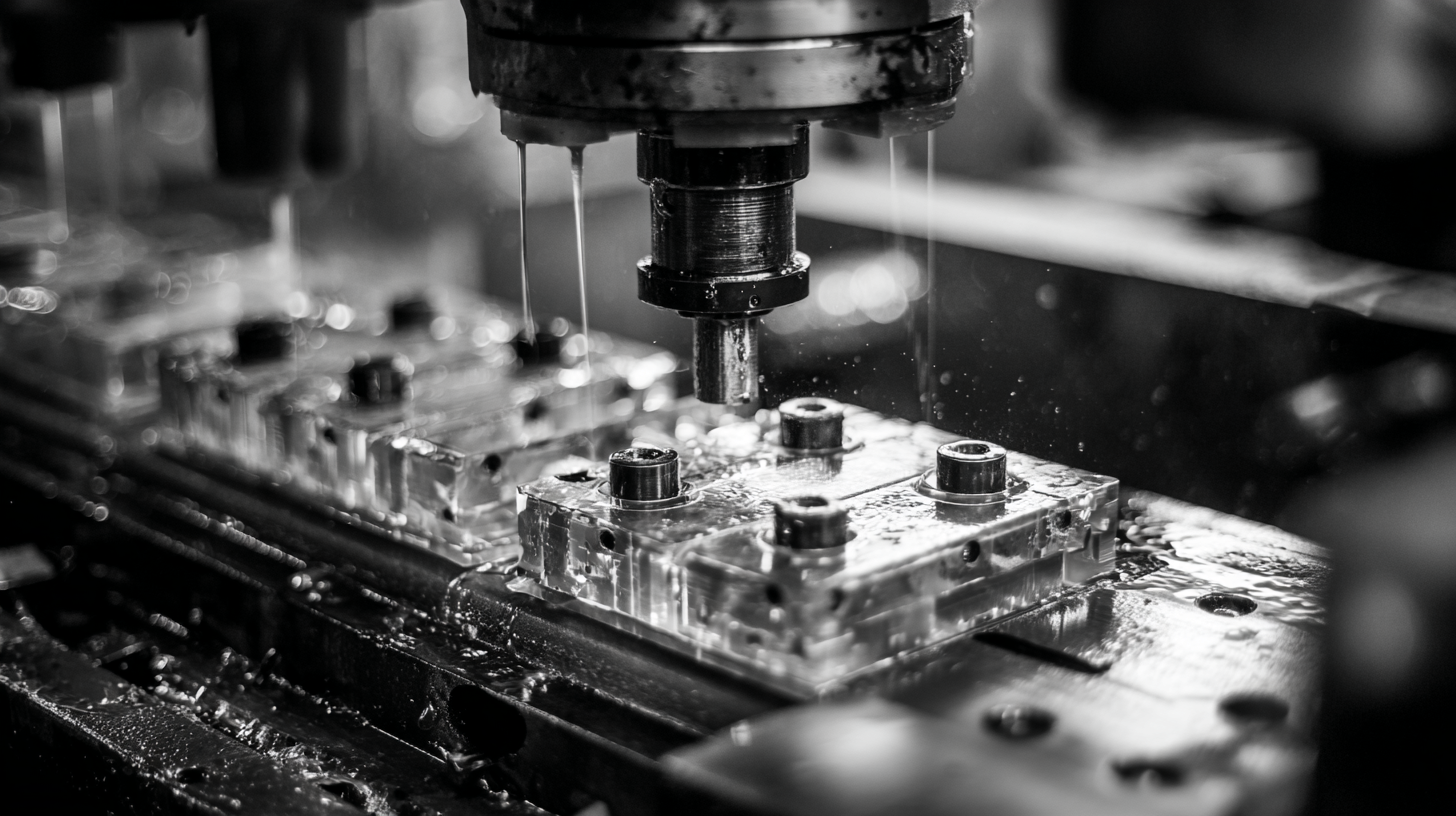

When it comes to efficient plastic molding operations, having the right equipment is crucial. Investing in high-quality injection molding machines can significantly enhance production speed and precision. Look for machines that offer adjustable settings for temperature, pressure, and speed to cater to various plastic materials and ensure consistent results. Additionally, consider the size and capacity of the machines, ensuring they align with your production needs to prevent bottlenecks.

Another essential piece of equipment is the mold itself. Choosing the right mold design can drastically impact the final product’s quality. Opt for molds made from durable materials to withstand repeated use, and pay attention to the mold cavities and cooling channels for optimal heat distribution. This enhances cycle time efficiency.

Moreover, regular maintenance of both machines and molds is vital. Create a maintenance schedule to inspect and clean your equipment, which helps prevent unexpected downtimes and prolongs their lifespan. Always keep an inventory of spare parts to minimize delays in case of repairs. By focusing on these essential elements, you can streamline your plastic molding operations effectively.

When it comes to plastic molding, minimizing defects is crucial for maintaining product quality and operational efficiency. According to a report by the American Society of Plastic Engineers, defects can cost manufacturers up to 20% of their total production expenses. Therefore, implementing effective best practices is essential to reduce these issues.

One effective tip is to optimize the cooling process. Proper temperature control is vital in ensuring that the plastic solidifies uniformly, reducing warping and surface blemishes. A study by the Society of Plastics Engineers highlights that an optimized cooling strategy can decrease cycle times by up to 20%, significantly enhancing productivity while minimizing defects.

Another important practice involves regular maintenance of molding equipment. Ensuring that machines are calibrated correctly and that molds are free from contaminants can drastically improve the quality of the final product. As per industry reports, manufacturers can reduce defect rates by as much as 30% through routine inspections and timely repairs. By focusing on these key areas, companies can achieve more reliable production and greater customer satisfaction.

Selecting the right materials for plastic molding is crucial for achieving optimal results in performance and cost-efficiency. According to a recent report by the Plastics Industry Association, nearly 80% of manufacturers cite material selection as a pivotal factor that influences product quality and sustainability. To aid in this process, here are some essential tips for choosing the ideal materials for your molding needs.

First, consider the application of the final product. Different applications require materials with specific properties. For instance, if you're producing components that need to withstand high temperatures or aggressive chemicals, high-performance polymers like PEEK or PTFE should be on your radar. Additionally, always evaluate the mechanical properties, such as tensile strength and impact resistance, to ensure the material can handle the stresses it will face.

Another critical tip is to factor in recyclability and environmental impact. The changing landscape of consumer preferences towards sustainable products means that selecting recyclable plastics can provide a competitive edge. The American Chemistry Council reported that about 30% of consumers are more likely to choose products made from recycled materials. Thus, opting for materials that incorporate recycled content not only supports sustainability but also enhances marketability.