As we look towards 2025, the landscape of injection molding materials is rapidly evolving, driven by technological advancements and shifting market demands. According to a report by Research and Markets, the global injection molding market is expected to reach a staggering $460 billion by 2025, showcasing a compound annual growth rate (CAGR) of 5.5%. This growth is largely fueled by the rising demand for lightweight and durable materials across various sectors, including automotive, medical, and consumer goods.

Dr. Emily Carter, a leading expert in polymer science, notes, "The future of injection molding materials lies in the integration of sustainable practices and innovative materials that enhance performance while minimizing environmental impact." Her insight underscores the importance of adapting to both consumer preferences and regulatory changes that favor eco-friendly solutions.

With the push towards more sustainable manufacturing processes, engineers and designers are increasingly turning to advanced thermoplastics and bioplastics as viable alternatives. This guide aims to explore the top injection molding materials trending in 2025, their applications, and the innovations setting the stage for a more resilient and sustainable future in the industry. By understanding these trends, stakeholders can make informed decisions that align with both market demands and environmental responsibilities.

The landscape of injection molding materials is evolving rapidly, driven by advancements in technology and shifting market demands. As we look ahead to 2025, several key trends are set to shape the future of these materials. One notable trend is the increasing demand for sustainability. Manufacturers are actively seeking bioplastics and recycled materials that reduce environmental impact while still providing the durability and efficiency needed for production. This shift not only aligns with global sustainability goals but also caters to consumers' growing preference for eco-friendly products.

Another significant trend is the rise of high-performance polymers, which are being developed to withstand more extreme conditions and applications. These advanced materials offer enhanced strength, heat resistance, and chemical stability, making them suitable for industries such as automotive, aerospace, and medical devices. Moreover, lightweight materials are becoming increasingly important as manufacturers strive to improve energy efficiency and reduce emissions in transportation. The integration of smart materials, which can respond to environmental changes or stress, is also on the rise, paving the way for innovative applications in various fields.

In summary, the key trends in injection molding materials for 2025 are centered around sustainability, performance enhancement, and adaptability to new technological advancements. As these materials continue to evolve, they will play a crucial role in meeting the demands of a changing market and pushing the boundaries of design and functionality.

| Material Type | Properties | Applications | Trends |

|---|---|---|---|

| Polypropylene (PP) | Lightweight, chemical resistant, good fatigue resistance | Automotive parts, consumer goods, packaging | Increasing use in sustainable applications |

| Acrylonitrile Butadiene Styrene (ABS) | Impact resistant, good surface finish, easy to paint | Consumer electronics, toys, automotive interiors | Growing demand in 3D printing and prototyping |

| Polyethylene Terephthalate (PET) | High strength, excellent moisture barrier, recyclable | Bottles, food containers, textiles | Rising focus on recycling and circular economy |

| Polycarbonate (PC) | High impact resistance, transparency, heat resistant | Safety goggles, electronic housings, eyewear lenses | Emerging trends in smart materials and electronics |

| Thermoplastic Elastomers (TPE) | Flexible, rubber-like properties, good UV resistance | Soft touch applications, seals, gaskets | Increase in demand for durable goods and components |

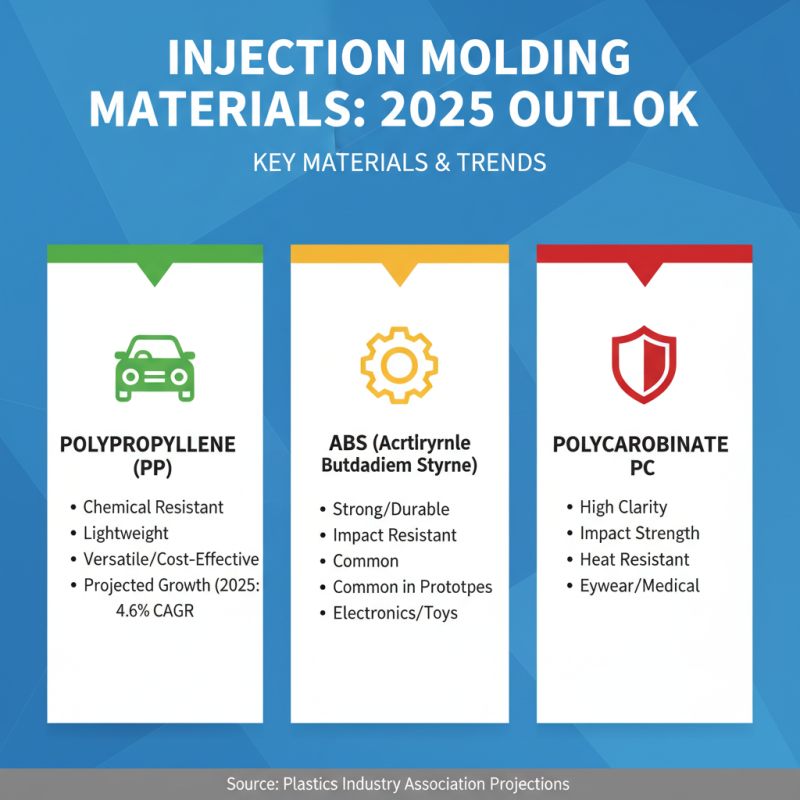

Injection molding is a critical manufacturing process, and the choice of materials is fundamental to the success of any project. As we look towards 2025, common injection molding materials such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC) continue to hold significant importance due to their unique properties. For instance, polypropylene is celebrated for its excellent chemical resistance and lightweight characteristics, which make it ideal for applications ranging from automotive components to consumer goods. According to the Plastics Industry Association, the demand for polypropylene is projected to grow at a compound annual growth rate (CAGR) of 4.6% through 2025, driven by its versatility and cost-effectiveness.

Meanwhile, ABS offers a balance of strength and impact resistance, making it a preferred choice for electronic housings and automotive interiors. Recent studies indicate that the global ABS market is expected to reach approximately $22.5 billion by 2025, illustrating the material's integral role in various sectors. Polycarbonate, known for its high strength and transparency, is also gaining traction, particularly in products requiring durability without compromising aesthetic qualities. As industries evolve, the selection of these materials should be guided by their specific properties, applications, and sustainability considerations, ensuring alignment with the emerging trends of 2025.

The injection molding industry is on the cusp of a transformative shift, driven increasingly by the demand for sustainable practices. Emerging biodegradable materials are at the forefront of this change, providing manufacturers with innovative options that reduce environmental impact. These materials, derived from renewable sources such as plant-based polymers, not only meet performance standards similar to traditional plastics but also offer the ability to break down naturally after use. This advancement aligns with global trends towards eco-friendliness, making biodegradable options a compelling choice for businesses looking to improve their sustainability profiles.

Incorporating these biodegradable materials into injection molding processes allows for the production of a wide range of applications, from packaging to consumer goods. Their versatility is enhanced by ongoing research and development aimed at improving the mechanical properties and processing characteristics of these materials. As the industry prepares for 2025, there is a growing focus on integrating these eco-friendly solutions into mainstream applications. This shift not only addresses consumer demand for sustainable products but also helps manufacturers comply with increasingly stringent environmental regulations, ensuring a balance between innovation and responsibility in the production landscape.

The landscape of advanced polymers continues to evolve, influencing a range of industries from automotive to medical devices. These materials are now engineered to meet specific demands, such as enhanced durability, reduced weight, and improved chemical resistance. For instance, in the automotive sector, lightweight and high-strength polymers are increasingly replacing metals, contributing to better fuel efficiency and lower emissions. Similarly, in the medical field, biocompatible polymers are vital for creating devices and implants that interact safely with the human body.

Tips: When considering the selection of polymers for your project, evaluate the specific performance requirements needed, such as temperature tolerance and mechanical properties. Collaborating with material scientists can also lead to innovative solutions tailored to meet evolving industry standards.

Furthermore, advanced polymers are making significant strides in the consumer electronics market. The demand for sleek, lightweight devices has led manufacturers to adopt high-performance plastics that not only provide aesthetic appeal but also enhance functionality. These materials are crucial in producing components that resist wear and tear while maintaining a lightweight profile, proving essential in a world where portability is key.

Tips: Stay informed on the latest advancements in polymer technology by attending trade shows and workshops. Engaging with industry experts can provide valuable insights that may give your projects a competitive edge in rapidly changing markets.

The realm of injection molding is poised for significant innovations as we approach 2025, with a focus on materials that enhance performance, sustainability, and efficiency. Advanced polymers and composites are leading the charge, offering improved mechanical properties and tailor-made characteristics for specific applications. For instance, bio-based materials are gaining traction, presenting a sustainable alternative that does not compromise on functionality or durability. This shift towards greener options is not merely a trend but a critical response to the growing demand for environmentally friendly manufacturing solutions.

In addition to material advancements, innovations in injection molding technologies are transforming production processes. Enhanced automation and smart manufacturing techniques incorporating artificial intelligence are streamlining operations, reducing waste, and improving precision. These technological improvements allow for greater customization and faster turnaround times, aligning with the market's need for both high-quality output and adaptive manufacturing. As businesses seek to remain competitive, embracing these future innovations will be vital in defining the next generation of injection molding applications, catering to diverse industries from automotive to consumer goods.