Injection molding is a critical process in manufacturing, enabling the production of complex and precise parts across various industries. As highlighted by Dr. Emily Carson, a renowned expert in materials engineering, "The selection of the right injection molding materials can not only enhance product performance but also significantly reduce manufacturing costs." This statement underscores the importance of understanding the different materials available for injection molding, as the choice of material can directly influence the overall success of a project.

In this guide, we will explore the top ten injection molding materials that every project manager and engineer should be familiar with. Each material comes with its unique properties and applications, making it essential for professionals to consider their specific requirements when selecting materials for their projects. Whether it’s strength, flexibility, or thermal resistance, the right injection molding materials can profoundly impact the final product's quality and efficiency. Join us as we delve into the characteristics, benefits, and potential use cases of these materials, empowering you to make informed decisions for your future manufacturing projects.

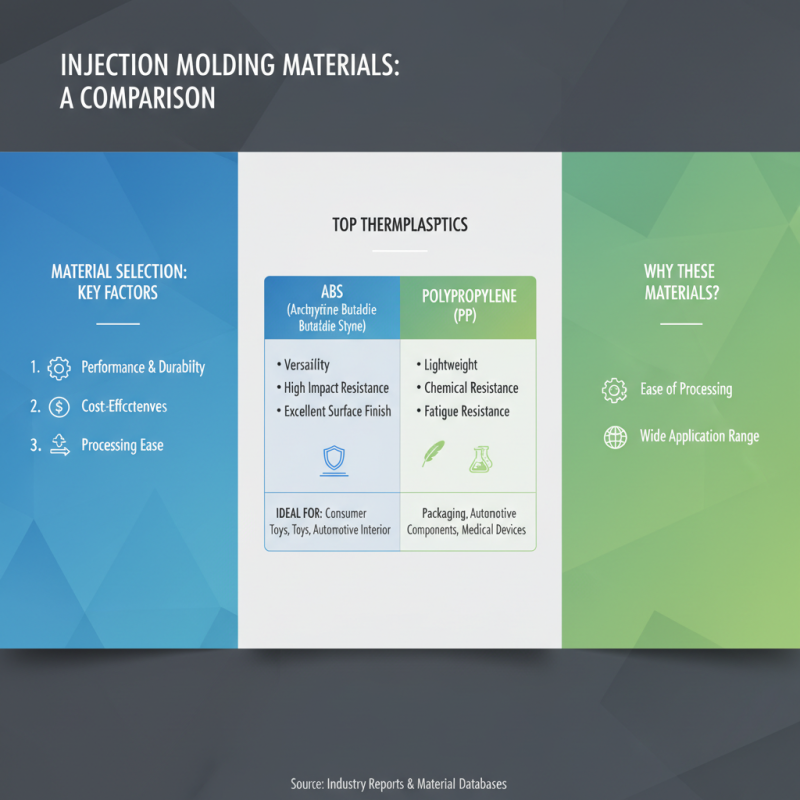

When embarking on an injection molding project, the choice of materials is critical to achieving the desired outcomes in terms of performance, durability, and cost-effectiveness. Among the top materials, thermoplastics like ABS and polypropylene are favored for their versatility and ease of processing. ABS, for instance, offers excellent impact resistance and surface finish, making it ideal for consumer products, while polypropylene is known for its lightweight nature and high chemical resistance, suitable for packaging and automotive components.

In addition to thermoplastics, engineering plastics such as polycarbonate and nylon play a significant role in more demanding applications. Polycarbonate is prized for its exceptional strength and transparency, which is ideal for applications requiring clarity and toughness, such as safety glasses and electronic housings. Nylon, on the other hand, provides superior wear resistance and strength, making it a choice material for industrial components and mechanical parts. Overall, understanding the properties and applications of these materials can greatly influence the success of injection molding projects, ensuring they meet both functional and aesthetic requirements.

Injection molding is a vital manufacturing process extensively used to create a variety of plastic components across countless industries. This technique involves injecting molten material into a mold to form intricate shapes and designs. The ability to produce high volumes of parts with consistent quality has made injection molding a cornerstone of mass production. It enables manufacturers to rapidly develop prototypes, ensuring efficiency in both time and cost, thus meeting market demands swiftly and effectively.

The importance of injection molding extends beyond mere production capabilities; it plays a significant role in material conservation and sustainability. Advanced injection molding techniques can minimize waste, making the process more environmentally friendly compared to traditional manufacturing methods. Additionally, with the improvement of material choices and technology, manufacturers can now utilize recycled materials, further enhancing the ecological benefits of this versatile process. Ultimately, mastery of injection molding techniques and materials is essential for engineers and designers, as it directly influences product performance, cost-effectiveness, and sustainability in manufacturing.

Polypropylene (PP) is one of the most widely used materials in injection molding applications, valued for its versatility and unique properties. With a melting point of approximately 160°C, PP exhibits excellent thermal stability, making it suitable for a variety of industrial applications. Its low density contributes to the lightweight nature of molded parts, while its high chemical resistance allows PP to withstand exposure to various chemicals and solvents. According to the Plastics Industry Association, PP accounts for about 21% of the global plastics market, reflecting its extensive utilization across numerous sectors, including automotive, consumer goods, and packaging.

When working with polypropylene in injection molding, it is crucial to consider its flow characteristics, as PP has a relatively high melt flow index (MFI). This property allows for easy processing, particularly in complex molds. Additionally, optimizing the cooling rates is essential to minimize warping and achieve dimensional accuracy. Tips for successful PP molding include maintaining proper temperature control and utilizing a well-designed gate system to ensure even material distribution.

While polypropylene is an exceptional material, it is vital to acknowledge the importance of additives and modifiers that can enhance its performance. For example, incorporating glass fibers can significantly improve its strength and stiffness, expanding its application potential. As the industry continues to evolve, staying informed about the latest advancements in polypropylene formulations will help you achieve the best outcomes for your injection molding projects.

Polyethylene (PE) is rapidly becoming a favored choice in the injection molding industry, primarily due to its cost-effective nature and versatile properties. One of the key advantages of PE is its favorable balance between performance and cost. According to a report from Grand View Research, the global polyethylene market size is expected to reach approximately USD 300 billion by 2025, driven largely by its applications in various industries such as packaging, automotive, and consumer goods. This growth is indicative of the material's efficiency and popularity among manufacturers seeking affordable yet robust solutions for their projects.

Moreover, polyethylene's excellent chemical resistance and low density make it ideal for a plethora of molding applications. Data from the Plastics Industry Association suggests that PE can reduce manufacturing costs by up to 20% compared to other materials, especially when considering bulk production. It allows for durable product designs that can withstand rigorous usage, while minimizing material waste during production. The ability to be easily recycled further enhances its sustainability profile, making it not only a cost-effective choice but also an environmentally friendly option in modern manufacturing processes. This combo of economy and functionality is what places polyethylene high on the list of preferred materials for injection molding projects.

Acrylonitrile Butadiene Styrene (ABS) is an exceptionally versatile thermoplastic that has become a favorite in various industries due to its unique combination of properties. Its high impact resistance and strength make it an ideal choice for applications requiring durability, such as automotive parts, household appliances, and consumer electronics. ABS can withstand considerable stress and impact, allowing it to maintain structural integrity in demanding environments. This resilience makes it particularly suitable for lightweight products where strength is a critical factor.

In addition to its mechanical properties, ABS is valued for its ease of processing. Its thermoplastic nature allows for straightforward injection molding, enabling manufacturers to create complex shapes and designs with precision. This attribute is further enhanced by its excellent surface finish, which can be easily painted and modified, allowing for greater aesthetic versatility. Coupled with its resistance to chemicals and heat, ABS stands out as a material that balances functionality and artistry, making it a go-to choice for designers and engineers looking to innovate across multiple sectors.

| Material | Properties | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Acrylonitrile Butadiene Styrene (ABS) | Impact resistant, lightweight, good heat resistance | Consumer electronics, automotive components, toys | Easy to machine, good surface finish | Not UV resistant, can warp under high temperatures |

| Polycarbonate (PC) | High strength, transparent, good heat resistance | Safety goggles, light covers, automotive parts | High impact resistance | Scratches easily without coating |

| Polypropylene (PP) | Chemical resistance, low density, flexible | Packaging, automotive parts, textiles | Recyclable, good resistance to stress and fatigue | Low UV resistance, can become brittle over time |

| Polystyrene (PS) | Brittle, good electrical insulator, cost-effective | Disposable cutlery, containers, insulation | Easy to mold, low cost | Low strength, not suitable for high-impact applications |

| Polyethylene (PE) | Flexible, tough, chemical resistant | Bottles, toys, plastic bags | Good moisture barrier, easy to process | Limited temperature resistance |

| Nylon (PA) | Strong, wear-resistant, good elasticity | Textiles, automotive components, industrial applications | High tensile strength, good fatigue resistance | Moisture absorption, can be expensive |

| Polyvinyl Chloride (PVC) | Durable, chemical resistant, versatile | Pipes, fittings, medical devices | Cost-effective, good fire resistance | Can become brittle over time |

| Polyethylene Terephthalate (PET) | Strong, lightweight, recyclable | Beverage bottles, food containers, textiles | Good barrier to moisture, strong | High melting point, can be more expensive |

| Thermoplastic Elastomer (TPE) | Flexible, rubber-like, good impact resistance | Automotive seals, consumer products, medical devices | Good flexibility and recovery | Higher cost compared to standard plastics |

| Polyurethane (PU) | Versatile, good abrasion resistance, flexible | Foams, automotive parts, coatings | Excellent durability, wide range of properties | Can be expensive, sensitivity to moisture |

Injection molding is a crucial manufacturing process that utilizes a variety of materials to create parts with precision and efficiency. Understanding the top injection molding materials can significantly impact project success. This article discusses the characteristics and advantages of several key materials, including Polypropylene (PP), which offers excellent chemical resistance and flexibility; Polyethylene (PE), known for its cost-effectiveness; and Acrylonitrile Butadiene Styrene (ABS), which is celebrated for its toughness and aesthetic appeal. Additionally, the role of Nylon (PA) in producing high-performance parts demonstrates how different injection molding materials can meet diverse project requirements, ensuring quality and functionality.