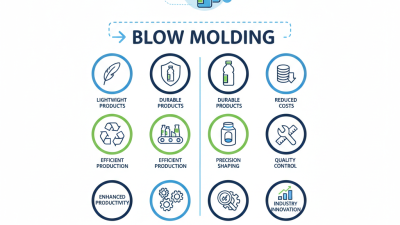

Blow molding is a widely used manufacturing process in the plastic industry. It creates hollow plastic parts by inflating heated plastic into a mold. This process is crucial for producing bottles, containers, and other products. Understanding the nuances of blow molding can significantly improve production efficiency and quality.

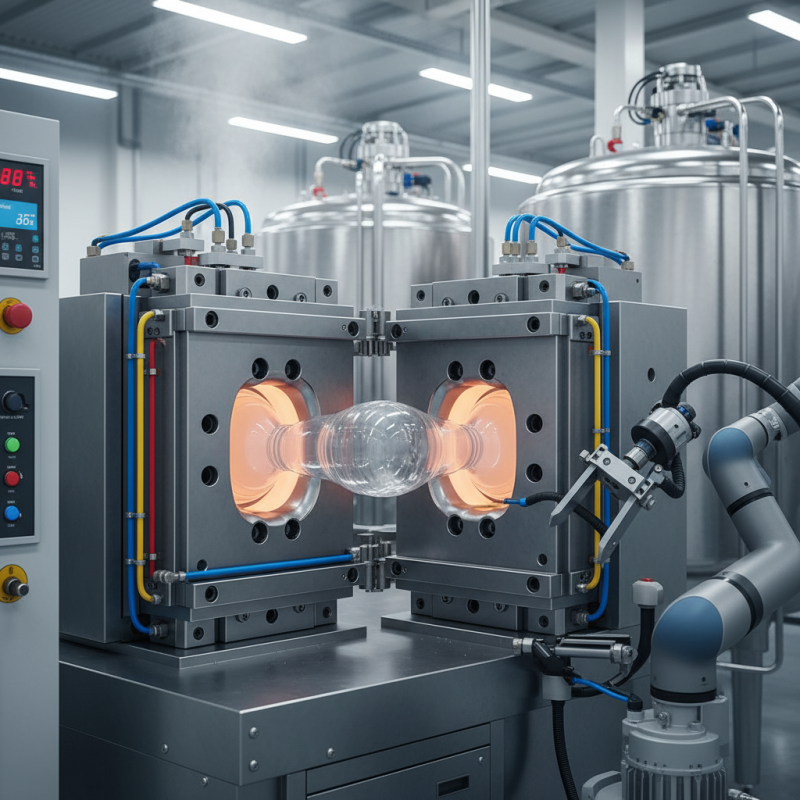

Mastering the blow molding process requires attention to various factors. For example, selecting the right material is vital. Each type of plastic behaves differently under heat and pressure. Moreover, the mold design plays a crucial role in achieving the desired shape. Small deviations can lead to defects, which will impact the final product's quality.

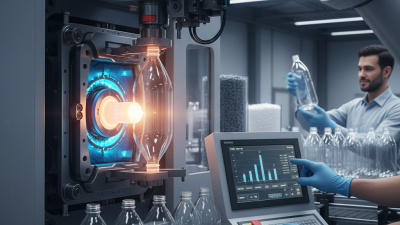

Manufacturers often overlook the importance of temperature control. Improper heating can cause inconsistencies in thickness and structural integrity. Additionally, while automation can enhance production rates, it may overlook minute details that require human oversight. Addressing these common pitfalls in blow molding will enhance process effectiveness and product quality.

Blow molding is a key technology in the production of plastic products. This process involves creating hollow plastic parts by inflating a heated plastic tube. The technique is widely used in packaging and manufacturing, producing items like bottles and containers. According to industry reports, the global blow molding market is projected to grow at a CAGR of 5.6% from 2022 to 2027. Understanding the basics of this technology is essential for optimizing production efficiency.

One crucial aspect of blow molding is selecting the right materials. Polyethylene and polypropylene are common choices. However, not all materials perform equally under different conditions. Misjudging material compatibility can lead to defects in finished products. Another element to consider is temperature control. Maintaining the right temperature can significantly impact the quality of the final product. Experts recommend a consistent temperature range to avoid common issues like uneven thickness.

Operators also need to pay attention to mold design. A poorly designed mold can cause problems during production. For instance, it might lead to uneven fill or air pockets. This can increase rejection rates and reduce overall efficiency. While many companies rely on standardized molds, customization may sometimes yield better results. Balancing cost and quality is a recurring challenge in the industry. Every decision made during the blow molding process can have lasting implications.

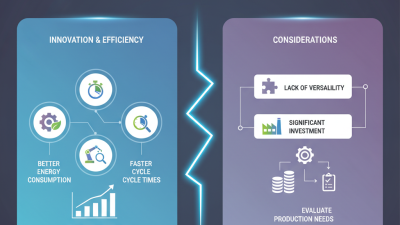

Blow molding is a crucial process in plastic manufacturing. The efficiency of this method largely depends on the equipment used. Essential machinery includes blow molding machines, mold sets, and downstream equipment. A survey by the Plastics Industry Association reveals that around 35% of manufacturers believe that outdated machinery impacts productivity. Upgrading to modern equipment can enhance precision and reduce waste.

The blow molding machine is the heart of the process. This device shapes molten plastic into desired forms. The right machine must match the production volume and product complexity. According to industry reports, companies using automated systems experience a 20% increase in efficiency. However, many businesses still rely on manual operations, resulting in inconsistent quality.

Molds are equally important. High-quality molds ensure accuracy and reduce defects. Regular maintenance is vital. Ignoring mold upkeep can lead to delays and increased costs. A study by the American Plastics Council indicates that 27% of production issues stem from poor mold conditions. This is an area often overlooked, yet it can greatly affect overall output.

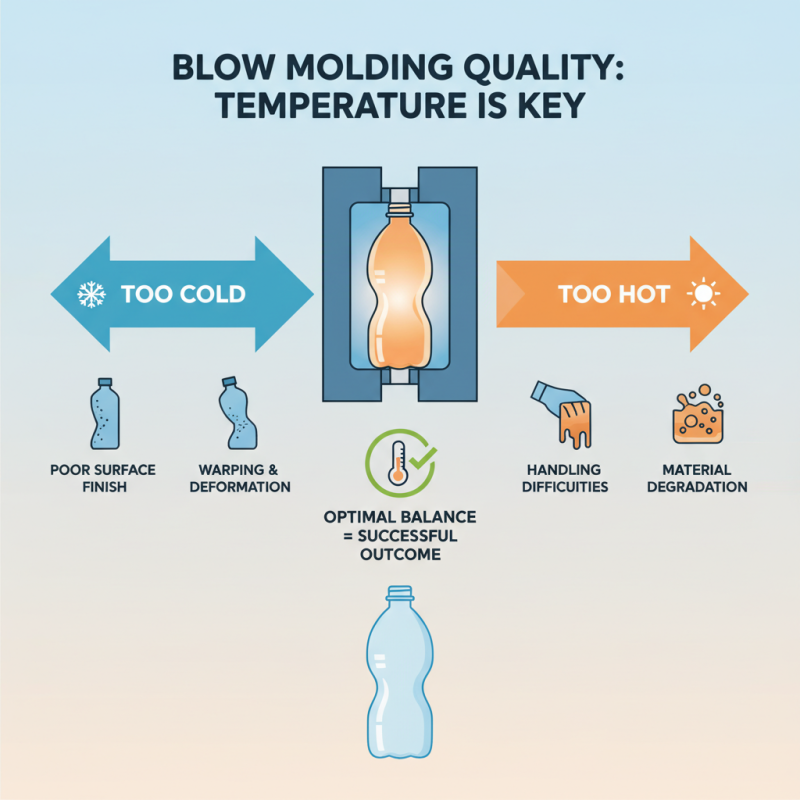

The blow molding process greatly relies on several key factors impacting its quality. Temperature control is crucial. If the mold or material is too cold, it can cause issues like poor finish or warping. On the other hand, excessive heat can make the material difficult to handle. Achieving the right balance is essential for a successful outcome.

Material selection also plays a significant role. Different materials have unique properties. Understanding these properties helps in choosing the right type for specific applications. For instance, some materials may lack strength, leading to premature failures. Testing materials before use can highlight possible shortcomings.

Pressure settings during the molding process should not be overlooked. If the pressure is too high, it may lead to defects. Conversely, low pressure can result in incomplete molds. Regularly checking and adjusting pressure settings ensures more consistent quality. Identifying mistakes in the process helps in refining future batches, which is necessary for continuous improvement.

Blow molding is an intricate process that comes with its own set of challenges. One common issue is maintaining consistent wall thickness in the final product. Variations can lead to weak spots and defects. Monitoring the temperature and pressure throughout the molding cycle is crucial. If the material isn't properly heated, it won't flow evenly, resulting in uneven walls.

Another challenge involves cycle time. If it's too long, production slows down. This can lead to increased costs and inefficiencies. Regularly assessing the machinery can help identify any issues. Adjusting the cooling times can also help enhance the overall efficiency.

Additionally, mold maintenance is essential. Over time, molds can wear down, affecting the quality of products. Regular cleaning and inspection are necessary. Small flaws can lead to larger problems down the line. Reflecting on these challenges can provide valuable insights. Continuous learning from past experiences is vital for meaningful progress in blow molding.

Maintaining blow molding machines and tools is crucial for efficiency and product quality. According to industry reports, proper maintenance can reduce downtime by up to 30%. However, many manufacturers overlook routine checks. This oversight can lead to increased repair costs and production delays. Regular maintenance should focus on critical components, such as the mold and cooling systems.

Ensure that your molds are free of debris and contaminants. A clean mold can reduce defects and improve cycle times. Lubricate moving parts to prevent wear and tear. Neglecting lubrication might result in machine failures and costly repairs. It’s essential to create a maintenance schedule and stick to it.

Training operators is another key aspect. Operators should be aware of the common signs of wear. They should notify supervisors when issues arise. This proactive approach leads to fewer breakdowns and more consistent production quality. Investing in training can be time-consuming, but the benefits are evident. A well-trained team is less likely to make avoidable errors during the blow molding process.