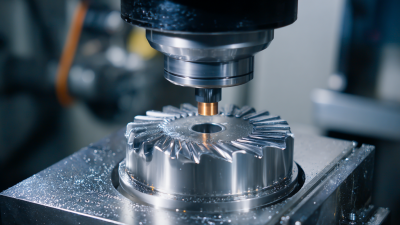

In the rapidly evolving landscape of manufacturing, companies are on a continuous quest for innovative techniques that streamline production while enhancing product quality. One such technique that has gained significant traction is rotational molding. As we look towards 2025, this manufacturing process is poised to revolutionize the production of top products across various industries. By allowing for the creation of complex shapes with uniform wall thickness and excellent structural integrity, rotational molding offers a versatile solution that meets the demanding needs of modern consumers.

The advent of advanced technologies and digital tools has further augmented the capabilities of rotational molding, enabling manufacturers to design and produce products with greater efficiency and precision. This transformation is not only beneficial for reducing waste and costs but also contributes to the sustainability goals that are becoming increasingly vital in today’s market. As we explore the potential of rotational molding techniques, this article will provide valuable tips and insights that can help businesses harness these innovations to stay ahead in the competitive manufacturing environment of 2025.

With the rise of innovative applications in manufacturing, rotational molding techniques are set to revolutionize the production of various top products by 2025. This method allows for the creation of complex shapes and large items with exceptional durability, making it an ideal choice for numerous industries, including automotive, consumer goods, and medical devices. By providing greater design flexibility and reducing material waste, rotational molding positions itself as a crucial technology for manufacturers looking to optimize their production processes.

Tip: Explore the use of copolymer linear low-density polyethylene (C6-LLDPE) in your rotational molding projects. This material offers excellent stress crack resistance and impact strength, making it suitable for products that require durability and longevity. As the market for C6-LLDPE continues to grow, projected to reach 25,094.28 metric tons by 2033, manufacturers can benefit from its enhanced properties for high-quality production.

Another advantage of rotational molding is its cost-effectiveness, especially for large-scale production runs. The process requires less energy and fewer resources compared to traditional manufacturing methods, allowing companies to streamline their operations. Embracing this technique not only fosters innovation but also paves the way for sustainable manufacturing practices in an increasingly competitive market.

The market for manufacturing is undergoing a significant transformation as companies increasingly adopt rotational molding techniques. This process, known for its efficiency and versatility, allows for the creation of complex shapes and lightweight products at reduced costs. As industries continue to innovate, the integration of rotational molding in product development is proving essential for meeting the diverse demands of consumers and enhancing competitiveness in the marketplace.

Rotational molding provides manufacturers with the ability to produce high-quality products that are not only durable but also customizable. This technique is particularly beneficial in sectors such as automotive, toys, and outdoor equipment, where the need for lightweight yet sturdy materials is paramount. The flexibility of rotational molding also supports rapid prototyping and short production runs, enabling companies to quickly adapt to changing market trends and consumer preferences.

As we look toward 2025, the pivotal role of rotational molding in driving product innovation and industry growth will become increasingly evident.

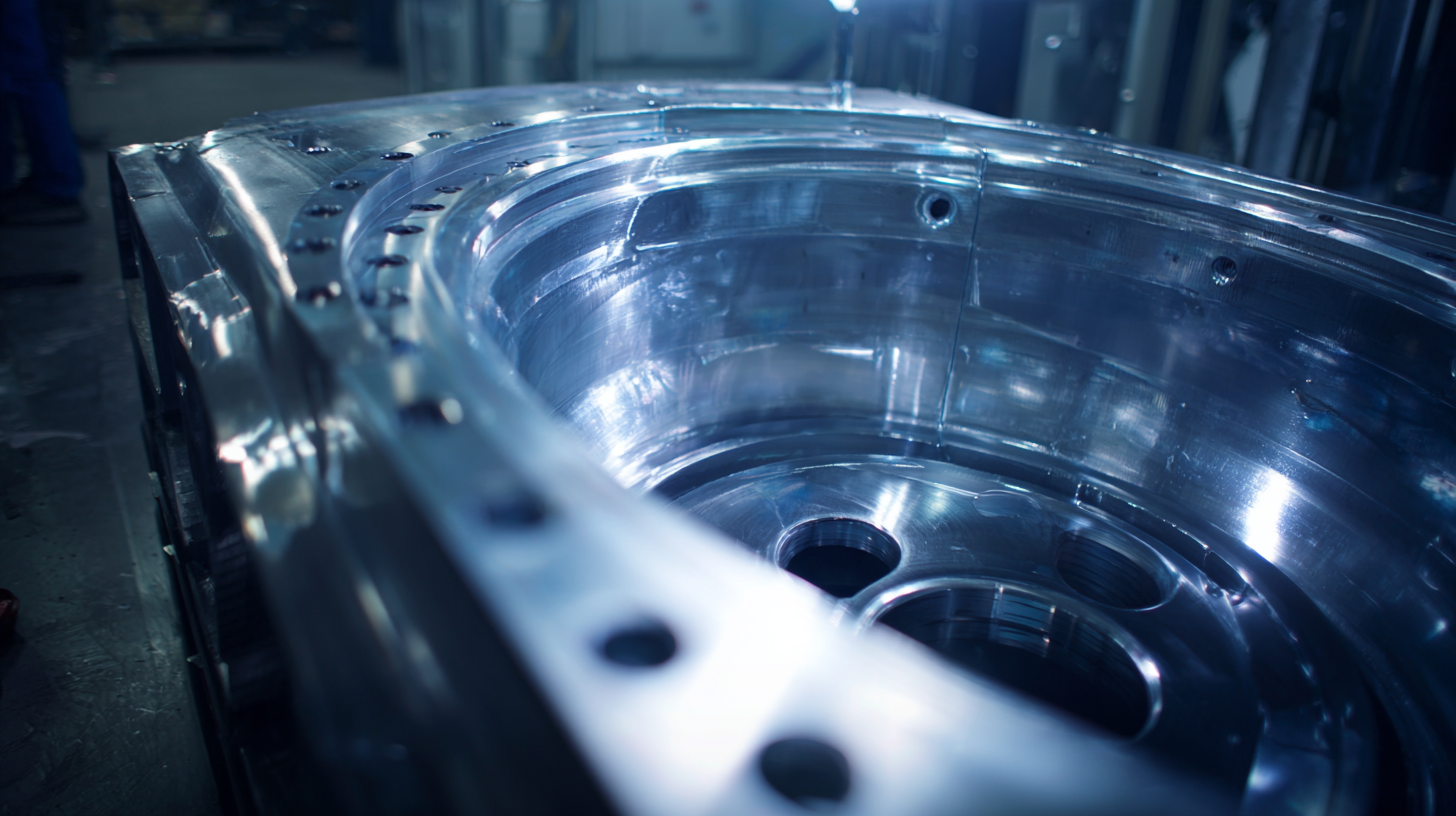

Rotational molding techniques are paving the way for a new era in manufacturing, particularly with a strong emphasis on cost efficiency and sustainability. This method allows for the creation of intricate shapes and large products without the need for expensive molds, significantly reducing production costs. By utilizing fewer materials and minimizing waste during the manufacturing process, rotational molding presents a practical solution for businesses looking to optimize their budget while maintaining high-quality outcomes.

Moreover, the sustainability aspect of rotational molding cannot be overlooked. The process enables manufacturers to utilize eco-friendly materials, including recyclable resins, which contribute to a reduced carbon footprint. Additionally, the energy-efficient nature of rotational molding means lower energy consumption compared to other methods like injection molding. As industries increasingly prioritize sustainable practices, rotational molding stands out as a forward-thinking technique that aligns with environmental goals, making it an attractive option for producing the top products of 2025.

Emerging trends in rotational molding are set to reshape the manufacturing landscape for 2025, fostering a wave of innovative products across various industries. As businesses look for sustainable solutions, the adoption of rotational molding techniques offers a unique advantage. This method enables the production of complex shapes with lower material waste, which results in a more eco-friendly process. Reports suggest that the rotational molding market is expected to grow at a CAGR of 5.6% from 2023 to 2030, highlighting its increasing significance in manufacturing.

One key trend is the customization capabilities offered by rotational molding, allowing manufacturers to tailor products precisely to consumer needs. This trend parallels the direct-to-consumer (D2C) approach seen in the beauty industry, where consumer preferences drive product innovation. Just as D2C brands have cultivated diversity and inclusion, rotational molding is facilitating the development of uniquely designed products that cater to demographic shifts and diverse market demands.

**Tips:** When considering rotational molding for your production needs, focus on sustainability by selecting eco-friendly materials. Additionally, invest in research to understand consumer trends and preferences, ensuring your products resonate with the target market. Lastly, collaborate with experts in rotational molding to leverage their knowledge and optimize your manufacturing processes for maximum efficiency.

| Product Category | Material Used | Applications | Benefits of Rotational Molding | Projected Growth Rate (2023-2025) |

|---|---|---|---|---|

| Storage Tanks | Polyethylene | Chemical Storage, Water Treatment | Durability, Corrosion Resistant | 5% |

| Playground Equipment | Polypropylene | Outdoor Recreation | Safety, Custom Shapes | 7% |

| Automotive Parts | PVC | Interior Components, Bumpers | Lightweight, Complex Designs | 6% |

| Containers | LDPE | Shipping, Storage | Seamless, Impact-Resistant | 4% |

| Home Goods | Polyethylene | Furniture, Decorative Items | Versatile Designs, Cost-Effective | 8% |

As the manufacturing industry evolves,

rotational molding emerges as a game-changer,

maximizing design flexibility and opening new avenues for product development.

This advanced molding process allows manufacturers to produce complex shapes and large components

with consistent wall thickness, which is essential for items like automotive parts and consumer goods.

A report from TechNavio indicates that the global rotational molding market is projected to grow by

7.5% annually, reaching approximately $3 billion by

2025. This significant growth underscores the increasing demand for versatile manufacturing techniques

that can adapt to changing consumer needs.

One of the key advantages of rotational molding is

its ability to accommodate a wide array of materials, including polymers that are both

lightweight and durable. The process facilitates the production of intricate designs

without sacrificing structural integrity, offering significant advantages in industries such as

aerospace and healthcare. According to a study by Smithers Pira, products crafted

through rotational molding can achieve cost efficiencies of up to

30% compared to traditional molding methods, enabling manufacturers to innovate

while keeping expenses in check. As we approach 2025, it's clear

that rotational molding will play a crucial role in redefining manufacturing capabilities

and fostering creativity across various sectors.