In today's competitive manufacturing landscape, mastering the art of plastic injection molding is essential for creating superior product designs that meet both functionality and aesthetic demands. This advanced technique not only allows for the efficient production of intricate components but also enables designers to leverage the versatility of various plastic materials. By understanding the principles and processes involved in plastic injection molding, innovators can enhance product performance, reduce waste, and ensure scalability in production. This guide will delve into the key elements of plastic injection molding, providing valuable insights and practical tips for designers and engineers alike, aiming to refine their skills and improve the overall quality of their products. Whether you are a novice or looking to fine-tune your expertise, mastering this process is vital for achieving excellence in product design.

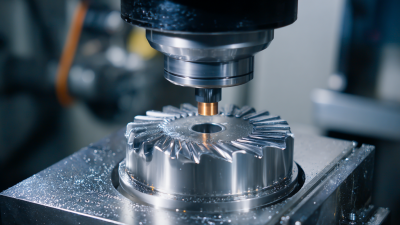

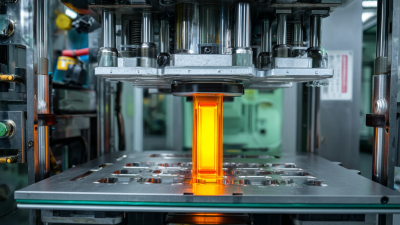

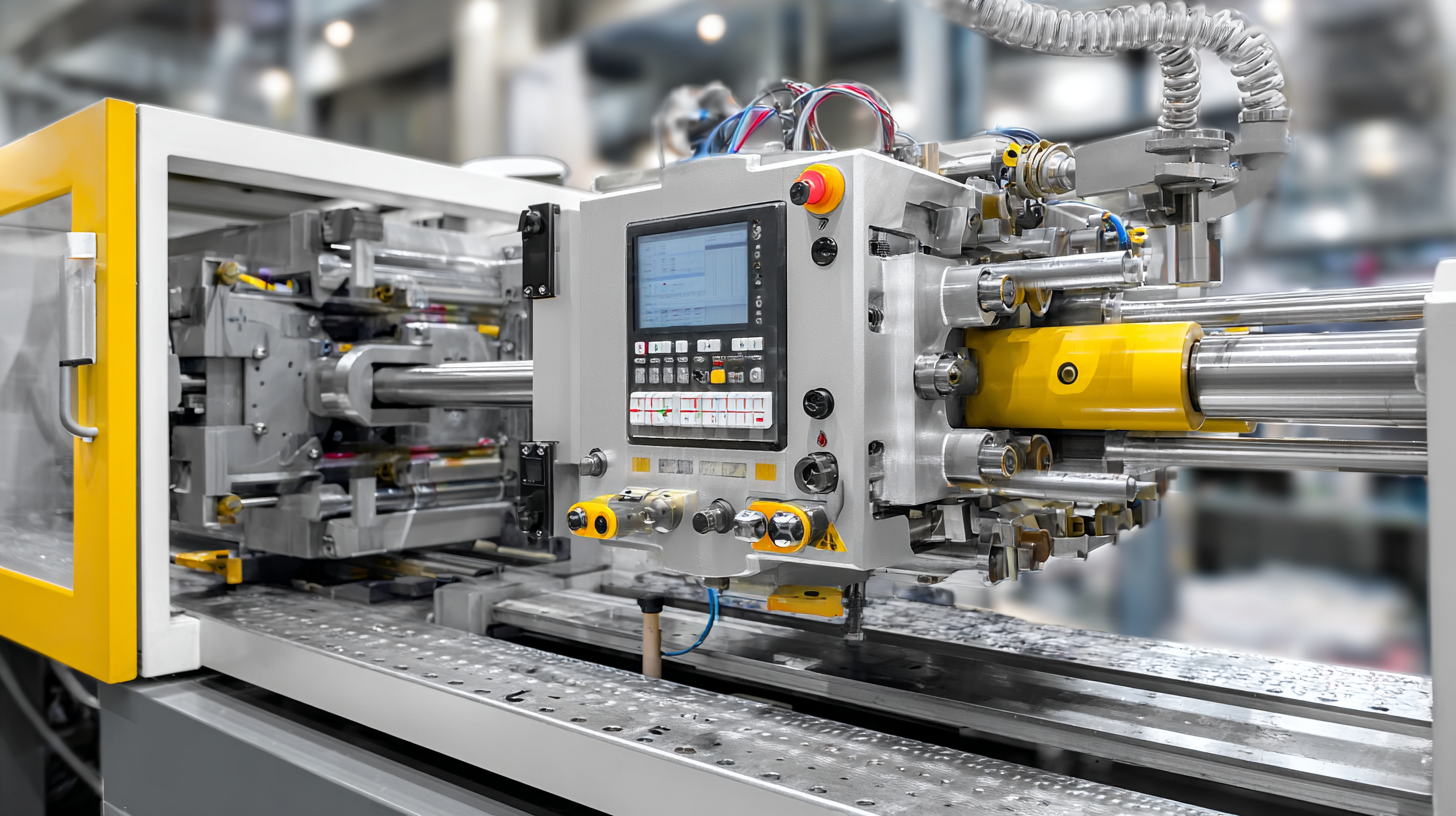

Plastic injection molding is a manufacturing process that allows for the creation of complex parts with high precision and efficiency. For beginners, understanding the fundamentals of this technique is crucial to mastering its intricacies. At its core, the process involves melting plastic pellets and injecting the molten material into a mold. This mold is designed to the specifications of the desired part, allowing for intricate shapes and fine details that are difficult to achieve using other manufacturing methods.

Key concepts in plastic injection molding include material selection, mold design, and process parameters. Beginners should familiarize themselves with various types of thermoplastics, as each material has unique properties that affect the final product's strength, flexibility, and durability. Moreover, the design of the mold itself requires careful consideration of factors such as wall thickness, draft angles, and gate placement to ensure optimal flow and cooling. By grasping these basics, novices can effectively enter the world of plastic injection molding and begin to design superior products that meet market demands.

Mastering the art of plastic injection molding requires a keen understanding of design optimization techniques that enhance efficiency and product quality. The injection molding process is intricate, comprising various stages, including material selection, mold design, and processing parameters. To achieve superior product design, it is essential to consider these elements early in the design phase.

**Tips:** Always prioritize the selection of appropriate materials based on the specific application and desired properties. For instance, LSR (Liquid Silicone Rubber) and LIM (Liquid Injection Molding) offer unique advantages, particularly in producing intricate designs that require flexibility and durability. Additionally, simulating the injection process using specialized software can help identify potential design flaws before physical production begins.

Another key technique involves simplifying part geometry to enhance manufacturability. Complex shapes can lead to challenges in mold creation and may increase production costs. By adopting a design-for-manufacture approach, designers can facilitate easier mold construction and avoid potential defects during the injection molding process. This proactive strategy not only boosts efficiency but also significantly shortens production timelines, ultimately leading to higher profitability.

Choosing the right materials is crucial for achieving superior outcomes in plastic injection molding. The type of material selected directly affects not only the performance and durability of the final product but also the efficiency of the manufacturing process. Common materials used in injection molding include thermoplastics such as ABS, polycarbonate, and polypropylene, each offering unique properties suited for different applications. For instance, ABS is known for its strength and impact resistance, while polycarbonate is favored for its excellent clarity and thermal resistance. Understanding the specific requirements of your product is essential in making an informed material choice.

Moreover, the selection process should also consider factors such as ease of moldability, cost-effectiveness, and environmental impact. Engineers and designers must work collaboratively to evaluate how each material behaves during the injection molding process, including its melt flow characteristics and cooling rates. By carefully selecting materials that align with the design objectives and production capabilities, manufacturers can achieve optimal results, minimizing defects and maximizing overall quality. Ultimately, a well-thought-out material choice lays the foundation for successful plastic injection molding and superior product design.

Designing for injection molding is a complex process that requires careful consideration to avoid common pitfalls that can lead to costly mistakes. One major error is insufficient draft angles on parts. According to a 2021 report by the Injection Molding Association, insufficient draft can increase the ejection forces required during production, which can compromise the integrity of the part and lead to increased wear on the mold. Ensuring proper draft angles, typically ranging from 1 to 5 degrees, helps facilitate easier ejection and prolongs the lifespan of the tooling.

Another prevalent issue is overlooking material selection. A study conducted by Plastics Technology highlights that inappropriate material choices account for up to 30% of injection molding defects. Designers must match the properties of the plastic with the functional requirements of the end product. For example, using a material with low impact resistance in an application where durability is essential can lead to product failure. It is crucial to balance aesthetic, mechanical, and thermal properties, as well as to consider the processing characteristics of different materials to optimize the design.

| Dimension | Description |

|---|---|

| Material Selection | Choosing the right plastic type for specific applications. |

| Design Complexity | Balancing intricate designs with manufacturability. |

| Wall Thickness | Maintaining consistent wall thickness to avoid warping. |

| Draft Angles | Incorporating appropriate draft angles for easier mold release. |

| Radii and Fillets | Using rounded corners to enhance strength and reduce stress concentration. |

| Shrinkage Considerations | Accounting for material shrinkage during cooling to ensure dimensional accuracy. |

| Gate Placement | Strategically placing gates to optimize flow and minimize defects. |

| Ventilation | Incorporating vents to prevent trapped air in molds. |

| Cooling System | Designing an efficient cooling system for uniform temperature control. |

The realm of plastic injection molding is witnessing significant innovations that are shaping the future of product design. As the market trends indicate substantial growth—projected to expand from USD 365.22 billion in 2024 to USD 580.44 billion by 2033—designers are increasingly leveraging advanced technologies to create more complex and efficient products. Key advancements include the integration of sophisticated material handling and temperature control equipment, which enhance processing efficiency and product quality.

Moreover, industry events are emphasizing the importance of innovation and networking, allowing professionals to explore cutting-edge technologies and trends. The focus is also on specialized sectors, such as micro injection molded plastics, which are experiencing remarkable growth, with projections estimating a CAGR exceeding 11% in the coming years. These trends indicate a vibrant landscape for future product design, underpinned by the continuous evolution of techniques and materials in the plastic injection molding industry.