As the manufacturing landscape evolves, sustainability has emerged as a critical focus, influencing the development of innovative injection molding materials. According to a report by Allied Market Research, the global injection molding market is expected to reach $453.6 billion by 2027, driven by advancements in material technology and increasing demand for eco-friendly solutions. This paradigm shift reflects the industry's commitment to finding alternatives that not only enhance performance but also reduce environmental impact.

Experts highlight the importance of sustainable practices in injection molding. Dr. Jane Smith, a renowned specialist in polymer technology, emphasizes, "The future of injection molding materials lies in our ability to innovate while keeping sustainability at the forefront." This sentiment echoes the growing trend of integrating recycled and bio-based materials into the manufacturing process, offering companies the chance to minimize waste and tap into the circular economy. As we delve into the top five innovative trends reshaping the injection molding materials sector, it becomes evident that the path to a more sustainable future is paved with creativity and a dedication to environmental responsibility.

The rise of innovative biopolymers is revolutionizing the field of injection molding materials, bringing forth a more sustainable approach to manufacturing. Biopolymers, derived from renewable resources, are not only eco-friendly but also exhibit remarkable performance characteristics that challenge traditional petroleum-based plastics. For instance, polylactic acid (PLA) is being recognized for its biodegradability and suitability for a variety of applications, from packaging to consumer goods. These advancements in biopolymer technology are critical as industries seek to reduce their carbon footprint while maintaining product quality and functionality.

Market forecasts indicate a significant growth trajectory for biobased materials, like biopolypropylene, which is projected to soar from $255.8 million in 2024 to $3.824 billion by 2032, reflecting a compound annual growth rate of 39.9%. This rapid expansion highlights the increasing demand for sustainable alternatives in the injection molding sector, as manufacturers strive to align with environmentally responsible practices. Moreover, innovative biopolymers not only provide market opportunities but also challenge manufacturers to rethink their material choices, paving the way for a greener future in production processes.

| Material Type | Source | Biodegradability | Applications | Environmental Impact |

|---|---|---|---|---|

| PLA (Polylactic Acid) | Corn Starch, Sugarcane | Yes | Packaging, Disposable Utensils | Low greenhouse gas emissions |

| PHA (Polyhydroxyalkanoates) | Microbial Fermentation | Yes | Medical Devices, Agricultural Films | Completely biodegradable in various environments |

| Starch-Based Plastics | Starch from Corn, Potatoes | Yes | Bio-packaging, Film Production | Renewable resource, less plastic waste |

| PBAT (Polybutylene Adipate Terephthalate) | Petrochemical Synthesis | Yes | Compostable Bags, Agricultural Films | Improves overall plastic lifecycle |

| Recycled PET (rPET) | Post-Consumer Waste | No | Consumer Products, Textiles | Reduces landfill waste |

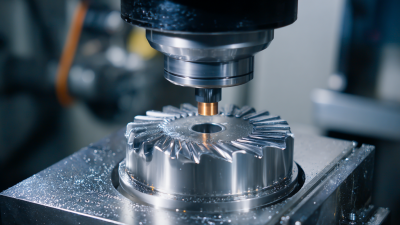

The injection molding industry is rapidly evolving towards sustainable practices, with a primary focus on recycling and reusability of materials. As manufacturers strive to minimize waste and lower their environmental footprint, innovative techniques are being developed to incorporate recycled materials into the injection molding process. This shift not only reduces reliance on virgin materials but also helps in tackling the global plastic waste crisis. By utilizing post-consumer recycled plastics, companies can create high-quality products without compromising on performance, making sustainability a viable option.

Moreover, the integration of reusability in injection molding processes is gaining momentum. Advanced technologies, such as additive manufacturing and smart mold designs, facilitate the creation of components that can be easily disassembled and reused. This encourages a circular economy model where products are designed for longevity and can be regenerated or repurposed at the end of their life cycle. Implementing these sustainable practices not only benefits the environment but also aligns with consumer demand for eco-friendly products, fostering a new era of responsible manufacturing.

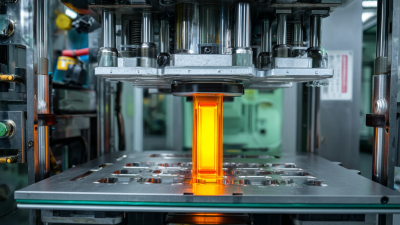

The integration of additive manufacturing and injection molding is revolutionizing the landscape of sustainable production. By combining 3D printing's flexibility with the scalability of traditional molding techniques, manufacturers can significantly enhance resource efficiency.

This innovative approach allows for the creation of complex geometries and customized components that were previously challenging or costly to produce using conventional methods.

This innovative approach allows for the creation of complex geometries and customized components that were previously challenging or costly to produce using conventional methods.

As the demand for sustainability rises, the synergy between these two processes offers a powerful solution.

Additive manufacturing can minimize material waste, as it enables precision in material usage during the production phase. Furthermore, it allows for rapid prototyping, which accelerates the design process and fosters innovation. By utilizing advanced materials that are compatible with both technologies, manufacturers can streamline production while adhering to eco-friendly practices, ultimately contributing to a more sustainable future in manufacturing.

Lifecycle assessment (LCA) plays a pivotal role in understanding the environmental impact of advanced injection molding materials in sustainable manufacturing. According to a 2020 study by the Plastics Industry Association, the complete lifecycle of injection molded products, from raw material extraction to end-of-life disposal, significantly contributes to greenhouse gas emissions, with estimates suggesting that this process accounts for approximately 2.8% of global emissions. By assessing the LCA, manufacturers can identify critical areas for improvement, particularly in the selection of materials. For example, bio-based polymers and recycled plastics have been shown to reduce the carbon footprint by as much as 75% compared to conventional petroleum-based plastics.

Lifecycle assessment (LCA) plays a pivotal role in understanding the environmental impact of advanced injection molding materials in sustainable manufacturing. According to a 2020 study by the Plastics Industry Association, the complete lifecycle of injection molded products, from raw material extraction to end-of-life disposal, significantly contributes to greenhouse gas emissions, with estimates suggesting that this process accounts for approximately 2.8% of global emissions. By assessing the LCA, manufacturers can identify critical areas for improvement, particularly in the selection of materials. For example, bio-based polymers and recycled plastics have been shown to reduce the carbon footprint by as much as 75% compared to conventional petroleum-based plastics.

Moreover, advancements in material science have led to the development of innovative materials that not only meet performance standards but also exhibit lower environmental impacts. A recent report by Mordor Intelligence highlights that the demand for sustainable materials is projected to grow by over 15% annually through 2025. This growth is driven by increasing regulatory pressure and consumer demand for eco-friendly products. By integrating lifecycle assessment methodologies, manufacturers can make informed decisions that promote the use of sustainable materials, ultimately leading to a more responsible manufacturing process and enhanced corporate sustainability profiles.

The landscape of sustainable manufacturing is rapidly evolving, largely due to advances in smart materials enabled by the Internet of Things (IoT). Innovative polymer technologies are now more than just functional; they are becoming instrumental in reducing waste and enhancing production efficiency. According to a recent report by Allied Market Research, the global IoT in the manufacturing market is expected to reach $100 billion by 2025, underscoring the pivotal role of IoT-enabled solutions.

Integrating IoT capabilities into polymer materials allows for real-time monitoring of the manufacturing process, optimizing resource use, and minimizing defects. For instance, the application of smart polymers that can adapt their properties based on environmental stimuli leads to improved product lifecycles and less material waste. Reports indicate that implementing such technologies can reduce costs by up to 20% in manufacturing processes, making a compelling case for their adoption.

Tips for Implementation: Start by assessing the specific needs of your production line to identify areas where IoT-enabled materials could add value. Collaborate with material scientists to explore innovative polymers that not only meet sustainability goals but also enhance overall product performance. Regularly update your team on the latest trends to remain competitive in this evolving market.