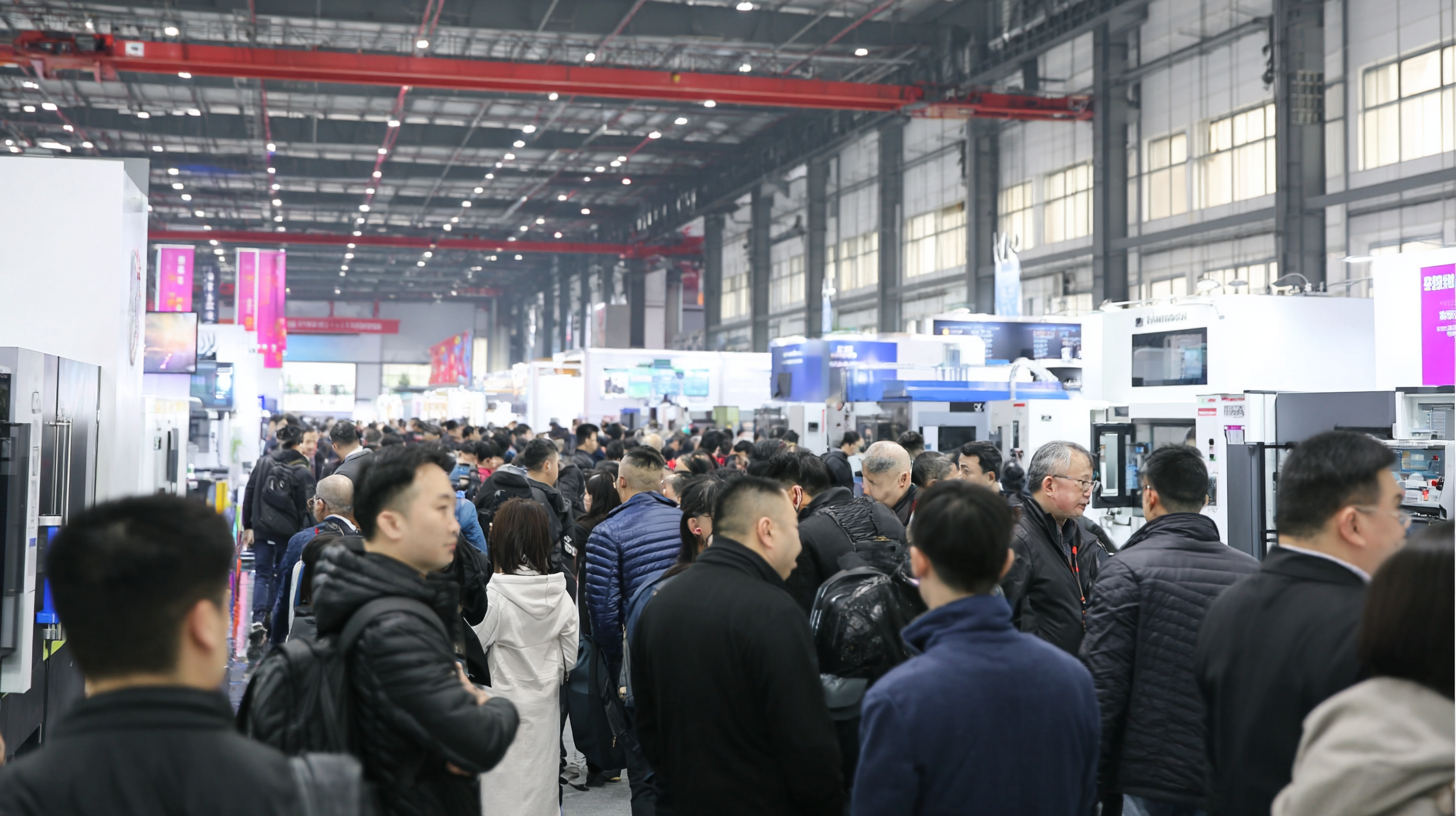

As the 138th China Import and Export Fair approaches in 2025, the spotlight will be on innovative manufacturing processes like rotational molding, a technique that continues to revolutionize the plastics industry. According to recent industry reports, the global rotational molding market is projected to grow at a CAGR of 5.3% from 2023 to 2030, driven by increased demand for cost-effective and lightweight molded products across various sectors, including automotive, consumer goods, and industrial applications. This molding process offers unparalleled design flexibility, minimal waste, and the ability to produce complex hollow items, making it an attractive choice for manufacturers seeking to enhance their product offerings. The upcoming fair will provide an essential platform for industry leaders to explore advancements in rotational molding technology, share insights, and forge valuable collaborations that could shape the future of the industry.

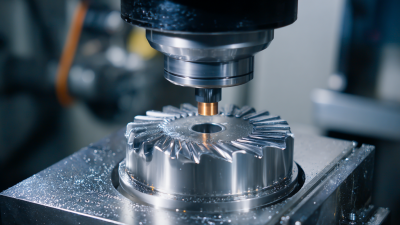

Rotational molding has emerged as a transformative technique in modern manufacturing, providing unique advantages in producing complex shapes with minimal material waste. According to a report by MarketsandMarkets, the global rotational molding market is projected to reach USD 6.54 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth reflects the increasing demand for custom-designed plastic products, which rotational molding readily accommodates. With its ability to create hollow parts with consistent wall thickness, this method is particularly valuable in industries such as automotive, consumer goods, and industrial applications.

The significance of rotational molding in contemporary manufacturing practices lies not only in its efficiency but also in its sustainability. The process generates significantly less scrap compared to traditional molding techniques, making it a more environmentally friendly choice. Furthermore, advancements in technology and materials have led to enhanced performance characteristics of the molded products, such as improved durability and resistance to UV degradation. As noted in the 2021 Plastics Industry Association report, innovative materials specifically designed for rotational molding are contributing to the method’s growing popularity, emphasizing its relevance in a modern, eco-conscious marketplace.

Rotational molding is gaining traction across various industries due to its versatility and cost-effectiveness. At the 138th China Import and Export Fair in 2025, manufacturers and innovators will showcase the latest advancements in this manufacturing technique, which allows for the creation of complex shapes and large hollow components. This method is particularly beneficial in sectors such as automotive, consumer goods, and packaging, where durability and design flexibility are paramount.

The use of C6-LLDPE (copolymer linear low-density polyethylene) is anticipated to play a significant role in the growth of rotational molding applications. The market size for C6-LLDPE is projected to increase from 18,835.01 million units in 2025 to 25,094.28 million units by 2033, reflecting an annual growth rate of 3.7%. As industries continue to seek materials that combine strength and lightweight characteristics, C6-LLDPE emerges as a preferred choice for rotationally molded products. The expansion of this material's market underscores the innovative applications of rotational molding, positioning it as a key player in the future of manufacturing.

The rotational molding industry is experiencing noteworthy innovations, particularly in the lead-up to the 138th China Import and Export Fair in 2025. As highlighted in a recent report by Smithers Pira, the global rotational molding market is projected to reach USD 6.1 billion by 2026, growing at a CAGR of 4.5%. This growth is driven by advancements in materials technology and process efficiencies, allowing for the production of lightweight and durable products across diverse applications.

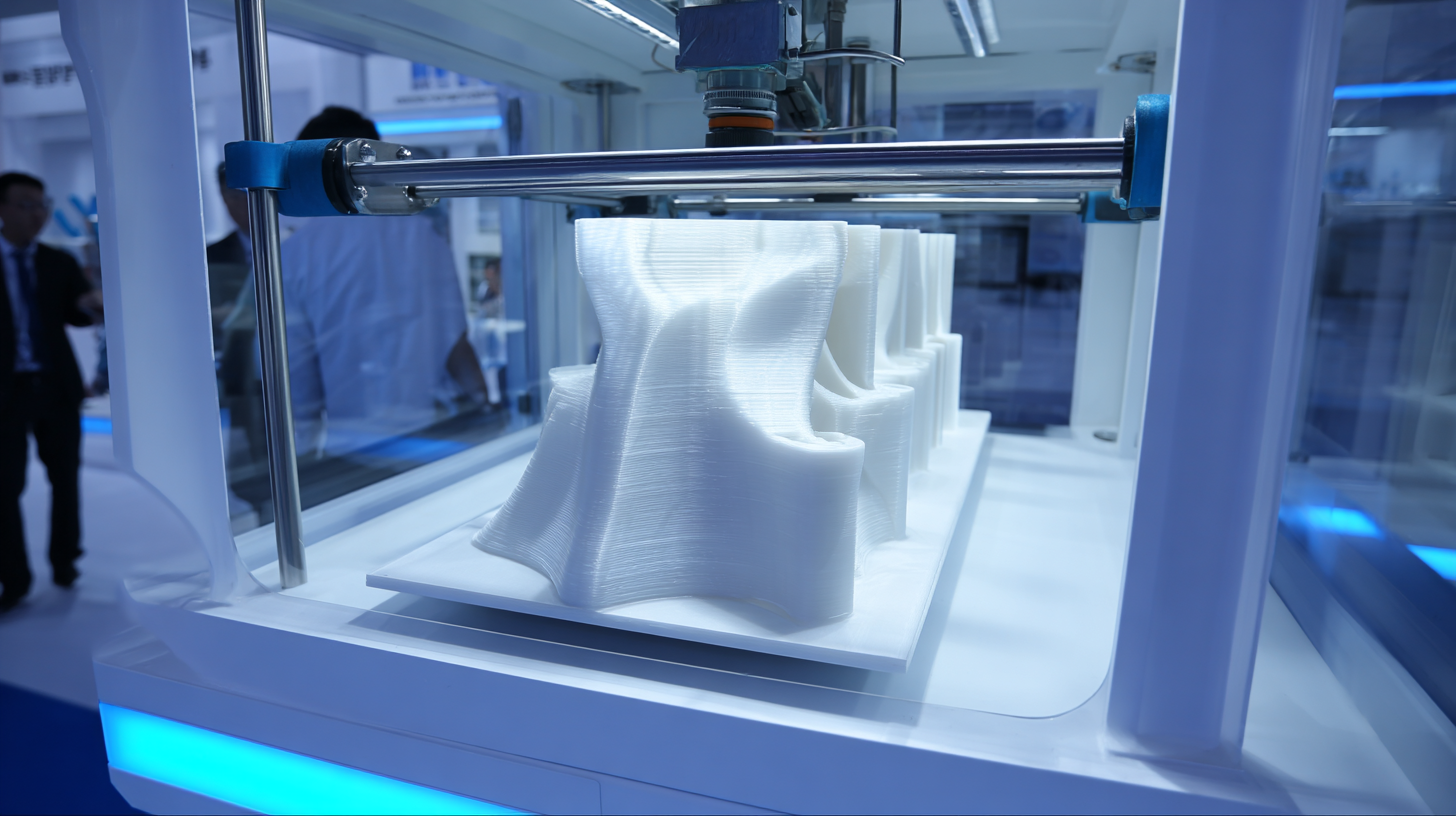

Key trends influencing the evolution of rotational molding technology include the adoption of more sustainable materials and the integration of smart technology into manufacturing processes. The rise of bioplastics, which are forecasted to capture 20% of the market by 2025, reflects a significant shift toward environmentally friendly production methods. Moreover, companies are increasingly utilizing automation and data analytics to optimize cycles and improve quality control, effectively reducing waste and energy consumption—factors critical in meeting stringent global sustainability standards.

These developments are set to showcase the future of rotational molding at the upcoming trade fair, where industry stakeholders will convene to explore collaborative opportunities and demonstrate cutting-edge techniques that promise to enhance efficiency and product versatility in the coming years.

| Trend/Development | Description | Impact on Industry | Future Outlook |

|---|---|---|---|

| Sustainable Materials | Use of eco-friendly resins and materials in the molding process. | Reduction in environmental impact and compliance with regulations. | Increased adoption of sustainable practices expected. |

| Automation in Processes | Integration of automation technology in molding processes. | Improved efficiency and reduction in labor costs. | Continued advancements in technology likely to enhance productivity. |

| Enhanced Design Flexibility | Ability to create complex and custom shapes. | Broader application across various industries. | Increased demand for customized solutions expected. |

| 3D Printing Integration | Combining 3D printing with rotational molding. | Faster prototyping and reduced time to market. | Growing trend towards digital manufacturing solutions. |

| Lightweight Materials | Development of lighter materials for reduced weight products. | Enhances fuel efficiency in transportation applications. | Will continue to gain traction in automotive and aerospace sectors. |

At the 138th China Import and Export Fair in 2025, rotational molding companies are showcasing a variety of innovative products that highlight their success stories. These companies have leveraged advanced techniques to create lightweight, durable, and customizable products, catering to a wide range of industries including automotive, consumer goods, and recreation. The fair serves as a vibrant platform for these businesses to demonstrate their capabilities and connect with potential clients from around the globe.

Among the success stories, several companies have made significant strides in sustainability by incorporating eco-friendly materials into their rotational molding processes. This commitment to sustainability not only enhances their marketability but also aligns with global trends towards responsible manufacturing. Attendees at the fair can explore a diverse range of applications, from ergonomic furniture to intricate industrial components, all made possible through the versatility of rotational molding. This event not only marks a milestone in showcasing technological advancements but also fosters networking opportunities that can lead to future collaborations and innovation within the industry.

Rotational molding is poised to redefine its role in global trade and commerce, especially highlighted by its presence at the 138th China Import and Export Fair in 2025. This innovative manufacturing process offers remarkable advantages, such as reduced waste and the ability to produce large, complex shapes that are often impossible with other molding techniques. According to a recent market analysis by Grand View Research, the rotational molding market is expected to reach $4.2 billion by 2027, growing at a CAGR of 4.5%. This growth is indicative of the increasing demand for lightweight and durable materials in various industries, including automotive, consumer goods, and industrial applications.

As businesses look to streamline production and reduce costs, rotational molding provides a sustainable solution that aligns with the ongoing global push for eco-friendly practices. For manufacturers, adopting this method can lead to lower material consumption and a reduced carbon footprint. A report from IBISWorld emphasizes that companies utilizing these practices may see a considerable competitive edge in international markets, as sustainability becomes a key purchasing factor for consumers.

**Tip 1:** Consider integrating rotational molding into your product line to capitalize on the growing trend towards lightweight and eco-friendly products.

**Tip 2:** Attend industry fairs, such as the China Import and Export Fair, to connect with key players and stay updated on the latest advancements in rotational molding technologies.

By embracing rotational molding, businesses not only enhance their operational efficiency but also position themselves favorably in the evolving landscape of global trade.