When it comes to selecting stainless steel woven wire mesh, many factors come into play. This type of material offers durability and versatility in various applications. From industrial uses to everyday items, understanding your specific needs is crucial.

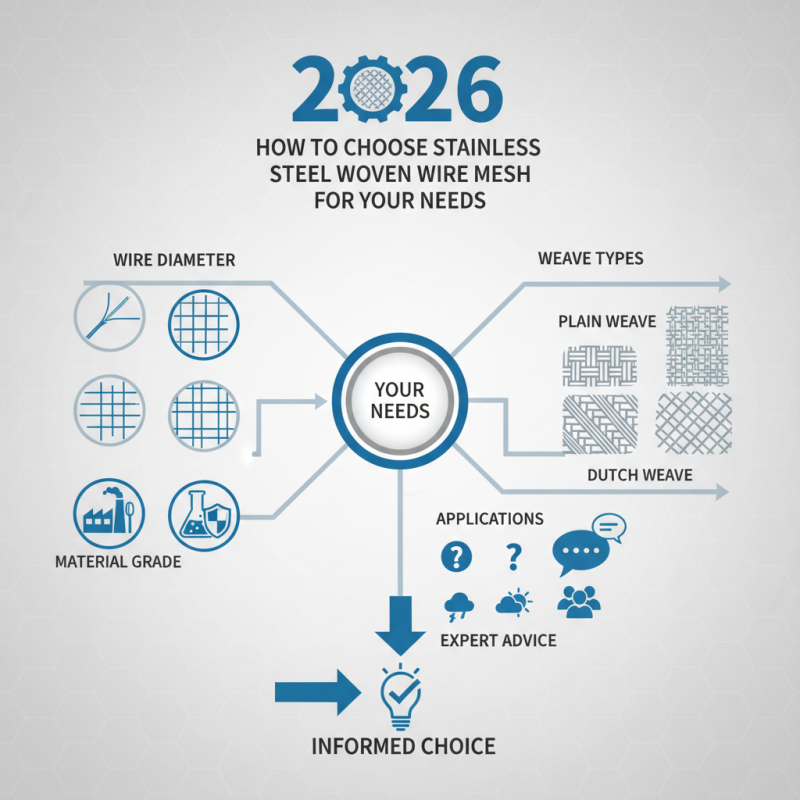

The quality of stainless steel woven wire mesh varies greatly. It is important to consider the wire diameter, mesh size, and material grade. Each detail affects strength and performance. Buyers often overlook the type of weaves available. Choosing the right weave can impact the mesh's functionality.

Make sure to ask the right questions. How will you use the mesh? Will it withstand harsh conditions? Seeking feedback from experienced users can help clarify your choices. Remember, the right decision starts with informed choices.

When selecting stainless steel woven wire mesh, understanding the types is crucial. There are various kinds available, each with unique characteristics. Woven wire mesh typically varies in terms of wire diameter, mesh opening, and weave pattern. Some options include plain weave, twill weave, and Dutch weave. Choosing the right option can affect the durability and functionality of the mesh.

Plain weave is simple and offers excellent strength. It's commonly used for filtration and separation tasks. Twill weave, on the other hand, provides flexibility and higher density. This type is often preferred for applications requiring more strength and rigidity. Dutch weave combines the properties of both plain and twill, making it suitable for fine filtration.

In practice, users often overlook the importance of mesh size. A mesh that is too coarse won’t effectively filter out small particles. Meanwhile, a mesh that is too fine can block flow. It's easy to make mistakes here. Assessing your specific needs is essential. Testing various options may lead to unexpected findings. Sometimes, trial and error reveals the best choice.

Choosing the right stainless steel woven wire mesh can be daunting. Key specifications, such as mesh size, wire diameter, and material grades, play vital roles in this decision. Mesh size determines the number of openings per unit length. A larger mesh size typically means smaller openings. Think about what you need the mesh for. Some tasks require tighter meshes, while others allow for larger openings.

Wire diameter impacts the strength and durability of the mesh. Thicker wires offer greater load-bearing capabilities. However, they may limit flexibility. A balance must be struck. Material grades, such as 304 or 316 stainless steel, affect corrosion resistance and longevity. Grade 316 is often preferred for marine environments. Pick the right grade based on your setting. Reflect on your specific needs, challenges, and the potential for wear over time. Each specification shapes your mesh choice. Make sure to evaluate carefully.

When selecting stainless steel woven wire mesh, consider how it interacts with environmental conditions. Corrosion resistance is a critical factor. Not all stainless steels are equal. Some grades withstand harsh environments, while others falter. For instance, marine areas with saltwater exposure demand higher resistance levels. A lower grade may rust and degrade quickly.

Environmental factors play a significant role. Pollution and humidity can also affect the durability of wire mesh. High humidity can promote rust, even in stainless steel. It’s essential to evaluate the location of installation. Industrial settings may have oil, chemicals, or other agents that compromise materials. Cleaning and maintenance are often overlooked. Regular upkeep can extend a mesh’s life, but it requires commitment.

Reflecting on your specific needs is vital. What will you use the mesh for? The right choice is hardly straightforward. Focusing on corrosion resistance may lead you to ignore other essential attributes. Different applications demand different properties. Balancing these aspects can be tricky. Take your time. Make informed decisions for a lasting solution.

Stainless steel woven wire mesh is versatile. It's used in various industries. In food processing, it ensures hygiene. Mesh panels filter out impurities. This is vital for product quality.

In the construction sector, stainless steel mesh serves as reinforcement. It's strong yet lightweight. Many architects choose it for durability. However, some projects may overlook its potential use.

Tips: Always consider mesh size. A finer mesh might be necessary for certain applications. Additionally, the weave pattern affects strength and flexibility.

In the mining industry, stainless steel mesh is crucial. It separates materials efficiently. Yet, not all companies use the right type for their needs. This can lead to operational setbacks.

Tips: Regular maintenance is essential. Even durable materials can wear down. Check for signs of rust or damage. Take preventive measures early. This will extend the mesh's lifespan.

| Application Area | Mesh Size (mm) | Wire Diameter (mm) | Material Grade | Typical Use Case |

|---|---|---|---|---|

| Food Processing | 2.0 | 0.8 | 304 | Filtering liquids and solids |

| Construction | 5.0 | 1.2 | 316 | Reinforcement and safety barriers |

| Mining | 3.0 | 1.0 | 304 | Sorting and sifting materials |

| Pharmaceutical | 1.0 | 0.5 | 316L | Sterilizing and filtering |

| Oil and Gas | 4.0 | 1.5 | 304 | Separation processes |

When considering stainless steel woven wire mesh, cost analysis is vital. Prices can vary widely based on material, weave type, and application. It's essential to evaluate the price per square foot. A lower upfront cost may seem attractive but could lead to issues later. Cheaper materials might wear out faster, incurring replacement costs.

Long-term value should also be part of your decision-making process. High-quality woven wire mesh often lasts significantly longer. This durability can translate into savings over time. Think about how often you'll need to replace cheaper options. Sometimes, investing in a more robust product initially pays off. It might feel like a larger expense now, but it can prevent future headaches.

However, not all high-priced materials guarantee quality. Research is essential here. Seek feedback from users who have made similar purchases. Listen to both the positives and negatives. Real experiences can unveil hidden costs or maintenance needs. Always weigh these factors against your specific needs for the project.