In the ever-evolving world of manufacturing, plastic injection molding stands out as a critical process that has shaped industries ranging from automotive to consumer goods. As we delve into the future of this innovative technique, it becomes essential to explore the latest advancements and trends that are set to redefine the landscape of plastic injection. New technologies, such as the integration of automation, artificial intelligence, and sustainable materials, are paving the way for faster production cycles, reduced waste, and improved product quality.

Moreover, the growing emphasis on eco-friendly practices and circular economy principles is prompting companies to rethink their approaches to plastic injection molding. This article aims to highlight the key innovations and trends on the horizon that could significantly impact the way manufacturers operate and adapt to the challenges of tomorrow, ensuring that plastic injection remains a pivotal element in modern manufacturing.

The landscape of plastic injection molding is on the brink of transformation, largely influenced by the introduction of biodegradable plastics. As industries increasingly recognize the environmental implications of traditional plastics, the shift towards more sustainable materials is gaining momentum. According to a market research report by Smithers Pira, the biodegradable plastic market is projected to grow at a CAGR of 20.9% from 2020 to 2025, indicating a robust shift in manufacturing practices.

Biodegradable plastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are being tailored for injection molding applications. These materials not only decompose under natural conditions but also offer comparable mechanical properties to conventional plastics. For instance, research from the European Bioplastics Association shows that production capacities for bioplastics will reach 2.5 million tons by 2024, paving the way for diverse applications across various sectors, from automotive to packaging.

Biodegradable plastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are being tailored for injection molding applications. These materials not only decompose under natural conditions but also offer comparable mechanical properties to conventional plastics. For instance, research from the European Bioplastics Association shows that production capacities for bioplastics will reach 2.5 million tons by 2024, paving the way for diverse applications across various sectors, from automotive to packaging.

Furthermore, advances in technology are enhancing the feasibility of integrating biodegradable materials into existing injection molding processes. Companies are investing in specialized equipment that can efficiently process renewable resources without compromising manufacturing efficiency. As this trend towards sustainability intensifies, businesses adopting biodegradable plastics will not only meet regulatory requirements but also align with consumer preferences for eco-friendly products.

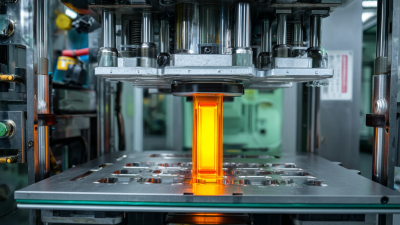

The integration of smart technologies like artificial intelligence (AI) and automation is revolutionizing the field of plastic injection molding. Advanced AI-driven systems enhance the molding process by automating repetitive tasks, optimizing production workflows, and reducing human error. These technologies leverage data analytics and machine learning algorithms to predict outcomes and improve efficiency. For instance, the latest developments in intelligent data-enabled design systems utilize deep semantic understanding to support complex mold design processes, thereby significantly boosting productivity.

Moreover, innovations such as simulation software enhance the accuracy of molding processes, allowing manufacturers to conduct detailed virtual testing before actual production. The adoption of robotics within the injection molding landscape points to a shift towards more sustainable and efficient manufacturing practices. Collaborating with collaborative robots (cobots) and digital twin technologies enables molders to respond rapidly to market demands while mitigating challenges related to labor shortages and increasing sustainability requirements. The ongoing fusion of AI and automation is not just transforming the production floor; it is setting the stage for the future of manufacturing in the injection molding sector.

| Dimension | Current Status | Future Trends | Impact of AI and Automation |

|---|---|---|---|

| Material Innovation | Mostly conventional plastics | Increase in bio-based and recycled materials | AI to optimize material selection and reduction in waste |

| Process Efficiency | Manual adjustments and monitoring | Fully automated processes with real-time adjustments | Automation systems to predict and correct process anomalies |

| Production Speed | Standard cycle times | Higher cycles through optimized molds | AI analytics improving cycle time predictions |

| Quality Control | Visual inspections and sampling | Automated inspection using machine learning | AI-driven analytics for defect prediction and prevention |

| Customization | Limited to predefined molds | Increased use of 3D printed molds | AI-assisted design tools for rapid prototyping |

As the plastic injection molding industry continues to evolve, sustainability has emerged as a critical focus area, prompting manufacturers to rethink their waste reduction practices. One of the key innovations is the adoption of bio-based materials that not only meet performance criteria but also minimize environmental impact. These alternative materials can significantly reduce the reliance on traditional petrol-based plastics and have been gaining traction due to their renewable sources and biodegradability.

Additionally, companies are increasingly implementing advanced recycling techniques to reclaim scrap materials generated during the injection molding process. Closed-loop systems, where waste is collected and reprocessed into new products, are becoming prevalent. Such practices not only lower costs by reducing the need for virgin materials but also contribute to a circular economy, enhancing brand reputation in an environmentally-conscious market. As technology continues to advance, the potential for real-time monitoring and process optimization will further empower manufacturers to minimize waste and improve overall efficiency in plastic injection molding.

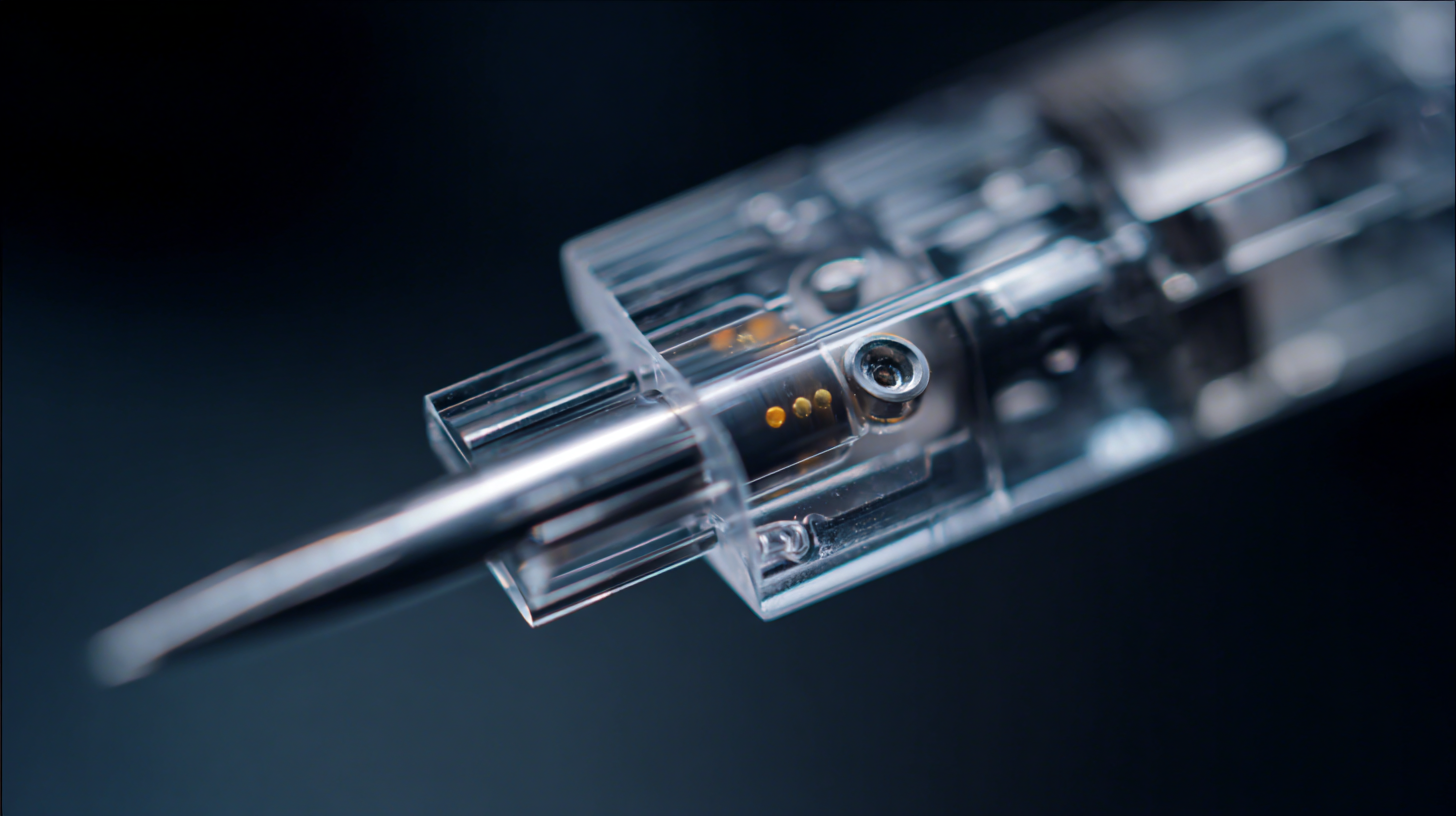

The landscape of plastic injection molding is evolving rapidly, propelled by innovations that prioritize customization and flexibility. Modern molding techniques now allow manufacturers to create highly specialized products tailored to consumer demands. This shift is largely driven by advances in computer-aided design (CAD) and simulation technologies, enabling designers to experiment with intricate shapes and functionalities before production. As a result, companies can produce smaller batch sizes without sacrificing quality, effectively catering to niche markets while minimizing waste.

In terms of design, modular molds are becoming increasingly popular. These molds can be easily adjusted or reconfigured, accommodating different products without the need for complete redesigns. Such flexibility not only reduces downtime during the transition between projects but also makes it feasible for manufacturers to stay agile in a competitive environment. Additionally, the integration of smart technologies and IoT in production lines facilitates real-time adjustments, ensuring that the final products meet the precise specifications that consumers are looking for. This trend toward customization and adaptability marks a significant shift in the way plastic injection molding operates, setting the stage for more responsive and innovative manufacturing practices.

The global plastic injection molding market is experiencing significant transformation, influenced by various challenges and opportunities. According to a report by Grand View Research, the market is projected to reach USD 463.6 billion by 2027, driven by the rising demand in industries such as automotive, consumer goods, and healthcare. However, the industry faces challenges, including fluctuating raw material prices and increasing environmental regulations. Companies must navigate these dynamics to maintain competitiveness and sustainability.

Innovations in injection molding technology are crucial for addressing these market dynamics. The adoption of advanced manufacturing techniques, such as additive manufacturing and automation, is expected to enhance production efficiency and reduce waste. A study by MarketsandMarkets highlights that the automation segment within injection molding is anticipated to grow at a CAGR of 7.4% from 2021 to 2026, reflecting the industry's shift toward smart manufacturing solutions. Furthermore, the integration of sustainable practices, such as the use of biodegradable plastics and energy-efficient machines, presents new opportunities for businesses aiming to meet both consumer and regulatory demands for greener products.