In the world of manufacturing, plastic injection molding stands out as a highly efficient and versatile process for producing intricate plastic parts and components. As industries increasingly rely on this technique for its cost-effectiveness and precision, mastering the nuances of plastic injection molding becomes essential for success. This article highlights ten essential tips that can guide professionals through the complexities of molding projects, ensuring quality results while minimizing waste and production time.

Understanding the intricacies of plastic injection molding is crucial for anyone looking to optimize their manufacturing processes. From material selection to mold design, each step plays a vital role in the overall outcome of the project. It is not just about getting the job done; it is about achieving excellence in every aspect of the process. By implementing these strategies, professionals can enhance their knowledge, improve efficiency, and ultimately produce superior products that meet or exceed industry standards. Whether you are new to the field or seeking to refine your existing practices, these tips will serve as a valuable resource for navigating your next plastic injection molding project with confidence.

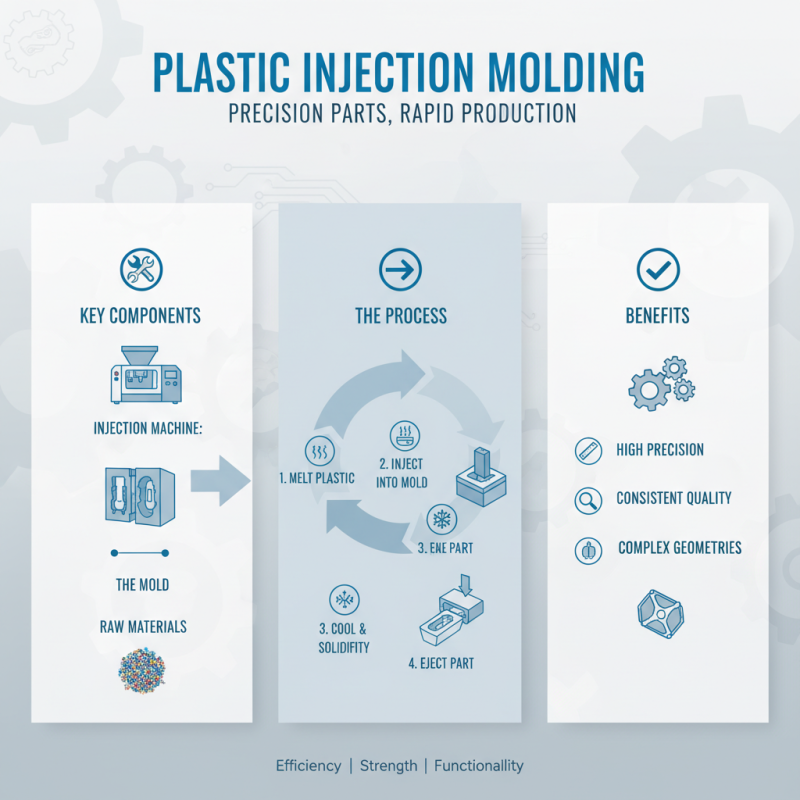

Plastic injection molding is a highly efficient manufacturing process used to produce complex parts with precision and consistency. At its core, this process involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired object. Understanding the basics of plastic injection molding is essential for ensuring the success of any project. Key components include the injection machine, the mold itself, and the raw materials. Each element plays a significant role in determining the final product's quality, strength, and overall functionality.

To embark on a successful plastic injection molding project, it is crucial to select the right type of plastic material based on the application's demands, as different plastics possess unique properties. Additionally, both the design of the mold and the operational parameters—such as temperature, pressure, and cooling time—must be meticulously planned and executed. By gaining a solid grasp of these foundational concepts, engineers and project managers can effectively troubleshoot issues, optimize production processes, and ultimately deliver high-quality molded parts that meet client specifications.

When embarking on a plastic injection molding project, understanding the key factors that influence success is crucial. First and foremost, material selection plays a pivotal role. The properties of the plastic chosen can significantly affect the moldability, strength, and durability of the final product. It is essential to select a material that not only meets the functional requirements of the product but also aligns with the manufacturing process. Working closely with suppliers and material specialists will help in making informed decisions that lead to better outcomes.

Another critical factor influencing the success of injection molding projects is the design of both the part and the mold. An effective design should consider aspects such as wall thickness, draft angles, and the inclusion of features that can facilitate the manufacturing process. Additionally, collaborating with experienced mold designers can mitigate common issues such as warping, sink marks, or material flow problems. Proper simulation and prototyping techniques can also identify potential challenges before the production phase begins, ensuring that projects remain on schedule and within budget.

When engaging in plastic injection molding projects, understanding the essential design considerations for both mold and part production is critical for achieving optimal results. A comprehensive study by the Society of Plastics Engineers highlights that nearly 70% of production issues can be traced back to inadequate mold design. This emphasizes the importance of careful attention to detail during the early stages. Key elements include ensuring proper venting, selecting the right materials, and maintaining dimensional accuracy, as even slight deviations can lead to significant production delays and increased costs.

Additionally, the design of the part itself plays a pivotal role in the success of injection molding projects. According to a report by Grand View Research, the plastic injection molding market size is expected to reach USD 344.78 billion by 2025, indicating the growing reliance on this manufacturing technique. Factors such as wall thickness, draft angles, and rib design must be considered to enhance the part’s functionality and manufacturability. For instance, maintaining consistent wall thickness helps avoid issues like warping or sink marks, while appropriate draft angles facilitate easier ejection from the mold, thereby improving cycle times and reducing wear on the tooling. By placing focus on these design considerations, teams can streamline their processes and enhance overall production efficiency.

Injection molding is a widely used manufacturing process, but it is not without its challenges. One common issue faced during plastic injection molding projects is achieving dimensional accuracy. Variations in temperature and pressure can lead to parts that do not meet specifications. To combat this, ensuring optimal mold design and conducting thorough testing can mitigate discrepancies. Regularly calibrating equipment and monitoring environmental conditions during production are vital steps to maintain precision.

Another significant challenge is material selection. The wrong choice can lead to problems such as poor surface finish, inadequate strength, or increased scrap rates. It’s essential to consider factors like the intended application, environmental exposure, and compatibility with the molding process. Engaging in early discussions with materials suppliers and utilizing simulation tools can aid in selecting the right polymer for the job. Additionally, proper drying and handling of materials prior to molding can further enhance the quality of the final product and ensure a smooth manufacturing process.

Quality assurance is a critical component of successful plastic injection molding operations. To ensure the production of high-quality parts, manufacturers must implement rigorous testing and monitoring protocols throughout the molding process. This begins with material selection, where using high-grade resins and additives can significantly influence the final product's durability and performance. Moreover, it’s essential to maintain precise temperature and pressure settings during injection, as even minor deviations can lead to defects like warping or incomplete fills.

In addition to process control, establishing a comprehensive inspection routine is paramount. Employing techniques such as visual inspections, dimensional checks, and advanced methods like ultrasonic testing can help identify potential issues early. Utilizing statistical process control can further enhance quality assurance efforts by providing data-driven insights into production consistency and variations. Regular training and skill enhancement for staff involved in quality assurance will also foster a culture of quality sensitivity, ensuring everyone understands their role in maintaining standards. Ultimately, these best practices will lead to improved reliability of the molding process and high customer satisfaction.