In today's rapidly evolving industrial landscape, the demand for effective and efficient storage solutions is more critical than ever, particularly when it comes to liquid materials. According to a recent report by Grand View Research, the global market for plastic storage tanks is projected to reach USD 1.17 billion by 2025, driven by their lightweight, corrosion-resistant properties and versatility across various sectors, including agriculture, chemicals, and water treatment. As businesses strive to optimize their operations and ensure regulatory compliance, selecting the right plastic storage tanks becomes essential. This guide aims to provide you with seven essential tips to navigate the complexities of choosing the ideal plastic storage tanks for your specific needs, ensuring safety, durability, and cost-effectiveness in your storage solutions.

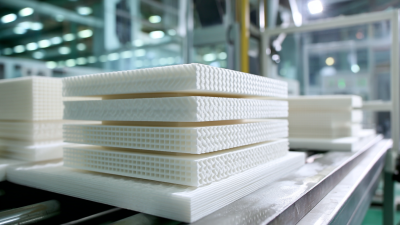

When it comes to selecting the right plastic storage tanks, understanding the various types available can significantly impact your decision-making process. Today’s market offers an array of options, including polyethylene, polypropylene, and PVC tanks, each with unique properties suited for specific applications. According to a recent market report by Global Industry Analysts, the global plastic tank market is projected to reach USD 2.5 billion by 2025, highlighting the material's growing relevance across industries.

Tip one: Consider the chemical compatibility of the materials. For example, while polyethylene tanks are ideal for storing water and some chemicals, polypropylene tanks are better suited for more aggressive substances due to their superior temperature and chemical resistance.

Tip two: Evaluate the tank's size and capacity requirements based on your projected usage. The right tank should not only meet current needs but also accommodate potential future growth; choosing a tank with a capacity that aligns with your operational demands will help avoid costly overflows or insufficient storage during peak times.

| Type of Tank | Material | Capacity (gallons) | Application | Cost Range ($) |

|---|---|---|---|---|

| Vertical Storage Tank | Polyethylene | 250 | Water, Chemicals | 300 - 600 |

| Horizontal Storage Tank | Polypropylene | 500 | Industrial Waste, Fuel | 500 - 1000 |

| Double-Walled Tank | High-Density Polyethylene | 1000 | Hazardous Materials | 1200 - 2500 |

| Food-Grade Tank | FDA Approved Polyethylene | 300 | Food & Beverage | 400 - 800 |

| Rainwater Harvesting Tank | Recycled Polyethylene | 1500 | Sustainable Water Supply | 700 - 1500 |

When selecting the right plastic storage tank, understanding the sizing is crucial to ensure efficiency and safety. According to the "Plastic Tank Market Report" by Grand View Research, the plastic tank industry is projected to reach $3.2 billion by 2025, highlighting the growing demand for customized solutions. One key factor to consider when sizing your tank is the intended application—whether for water storage, chemicals, or food products. Each application has specific requirements that determine the tank's size, shape, and material compatibility.

Another important aspect is the projected usage rate. For instance, if the tank is intended for seasonal use in agricultural applications, it should accommodate peak demand periods. The American Chemistry Council reports that more than 60% of plastic storage tanks are utilized in industrial settings, emphasizing the importance of planning for capacity based on not only current but future usage. Additionally, organizations should account for regulations and industry standards, ensuring that the tank size adheres to local environmental guidelines and safety protocols. By focusing on these factors, businesses can make informed decisions that align their storage needs with operational demands.

When selecting plastic storage tanks, the material and durability are paramount to ensuring they meet your specific needs. Various types of plastics offer different properties, making it crucial to understand the advantages and limitations of each. Polyethylene is a popular choice due to its excellent chemical resistance and affordability. It’s particularly effective for storing water and other non-volatile liquids. For more demanding applications, consider high-density polyethylene (HDPE), which provides enhanced strength and can withstand harsher environments.

While the type of plastic is critical, the durability of the tank under various conditions is equally important. Factors such as UV exposure, temperature variations, and chemical compatibility must be considered. For outdoor use, opt for tanks that are treated to resist UV rays and can handle fluctuating temperatures without degrading. Additionally, if the tank will be storing chemicals, ensure it’s made from materials specifically designed to prevent leaching and maintain structural integrity. By prioritizing these aspects, you can choose a storage tank that not only meets regulatory requirements but also stands the test of time.

When selecting plastic storage tanks, assessing environmental conditions is crucial, particularly when deciding between indoor and outdoor use. Outdoor tanks face harsher elements such as UV exposure, temperature fluctuations, and potential physical damage from environmental factors like wind or snowfall. According to the Plastics Industry Association, durable polyethylene tanks can withstand temperatures between -40°F and 120°F, making them suitable for various outdoor applications, but protective measures like UV stabilizers are essential to prolong longevity.

Conversely, indoor storage tanks can benefit from a more controlled environment, which can enhance the tank's performance and reduce maintenance needs. For instance, studies from the American Society for Testing and Materials show that indoor tanks tend to have a longer service life due to consistent temperatures and reduced exposure to the elements. Furthermore, the risk of contamination or degradation is lower indoors, making it an ideal choice for sensitive materials or chemicals. Ultimately, understanding your specific environmental conditions will guide you to the right plastic storage tank for your needs.

When selecting plastic storage tanks, regulatory compliance is a critical consideration. Industry standards, such as those set by the American Society for Testing and Materials (ASTM), provide guidelines that ensure the safety and effectiveness of storage solutions. For example, ASTM D1998 outlines the performance requirements for polyethylene tanks, ensuring they can withstand environmental stress and chemical exposure. Integrating compliance checks can help businesses avoid costly penalties and ensure safe operations.

A key tip when choosing plastic storage tanks is to thoroughly assess the tank's material and its compatibility with the substances you intend to store. For instance, certain chemicals can degrade plastic materials, leading to leaks or failures. According to a report from the National Association of Corrosion Engineers (NACE), improper material selection contributes to approximately 20% of storage tank failures. Ensure that the tank is designed to meet the specific chemical characteristics of its intended contents.

Furthermore, consider the certification and testing documentation of your potential storage tanks. Tanks that come with certifications from recognized bodies such as the Underwriters Laboratories (UL) or the National Fire Protection Association (NFPA) attest to their compliance with safety standards. This not only enhances operational reliability but also provides peace of mind that your storage solution adheres to the highest industry practices. By prioritizing regulatory compliance, you safeguard both your business and the environment.