CNC machining has revolutionized the landscape of precision manufacturing, providing unparalleled accuracy and efficiency in the production of intricate parts and components. This advanced technology employs computer-controlled machines to precisely cut, shape, and fabricate materials, enabling manufacturers to achieve specifications that were once challenging or even impossible to meet. With its ability to minimize human error and maximize production rates, CNC machining is becoming the preferred solution for industries ranging from aerospace to medical devices.

The benefits of CNC machining extend beyond mere precision. This technology also offers significant advantages in terms of design flexibility, repeatability, and scalability. Manufacturers can easily adapt to changing production demands without compromising quality, making CNC machining an ideal choice for both low and high-volume production runs. Moreover, it enhances operational efficiency by reducing material waste and decreasing lead times, ultimately leading to cost savings that can be reinvested into innovation and growth. As businesses continue to seek competitive edges in a fast-paced market, CNC machining stands out as a pivotal component in the realm of modern manufacturing solutions.

CNC machining has revolutionized the realm of precision parts production, offering unparalleled accuracy and efficiency. One of the primary advantages of this technology lies in its ability to maintain tight tolerances, which is crucial in industries such as aerospace, automotive, and medical devices. Utilizing computer numerical control, CNC machines can execute complex designs with a high degree of repeatability, ensuring that each part produced meets the specified dimensions and quality standards. This automation minimizes human error and allows for greater consistency across large production runs.

Another significant benefit of CNC machining is its versatility in handling a variety of materials, including metals, plastics, and composites. This adaptability not only broadens the potential applications of CNC machined components but also facilitates rapid prototyping and customization to meet the unique demands of clients. As manufacturing trends shift towards more intricate designs and smaller production quantities, CNC machining provides an agile solution that can quickly adjust to new specifications without significant lead times. Overall, the advantages of CNC machining in precision parts production ensure enhanced quality, reduced waste, and improved time-to-market for manufacturers across various sectors.

CNC machining has revolutionized the landscape of precision manufacturing by providing enhanced accuracy and consistency in production processes. One of the primary advantages of CNC technology is its ability to produce intricate components with extremely tight tolerances. The computerized controls guarantee that each cut and movement is executed with exact precision, minimizing the variability often seen in manual machining. This level of accuracy ensures that parts fit together perfectly, which is crucial in sectors such as aerospace and automotive, where even the slightest deviation can lead to significant issues.

In addition to accuracy, CNC machining significantly improves the consistency of manufactured products. Once a design is programmed into the CNC machine, it can replicate the process endlessly without any decline in quality. This reproducibility allows manufacturers to scale up production without worrying about variations in output. Consistency is vital not only for maintaining quality but also for establishing a reliable supply chain that meets market demands.

**Tips for Maximizing CNC Machining Accuracy:**

- Always verify the initial setup of your CNC machine to ensure that all parameters are correctly configured.

- Utilize advanced tools such as probing systems that can detect discrepancies in real-time during the machining process.

- Regularly maintain and calibrate your CNC equipment to uphold its precision and performance over time.

CNC machining offers significant cost-effectiveness, especially when it comes to mass production. By utilizing computer-controlled machinery, manufacturers can produce high volumes of parts with consistent precision and reduced material waste. This eliminates the need for numerous manual adjustments, which can be time-consuming and prone to errors, ultimately streamlining the production process. With automated operations, labor costs can also be minimized, allowing companies to allocate their resources more efficiently.

Moreover, the ability to create complex designs without a significant increase in production costs is another advantage of CNC machining in mass production settings. Traditional manufacturing methods often require specialized tooling and setups for different designs, which can escalate expenses. In contrast, CNC machines can be quickly reprogrammed to produce various parts, enabling manufacturers to adapt to changing market demands without incurring excessive costs. This flexibility ensures that companies can remain competitive while maintaining high standards of quality and precision in their manufacturing processes.

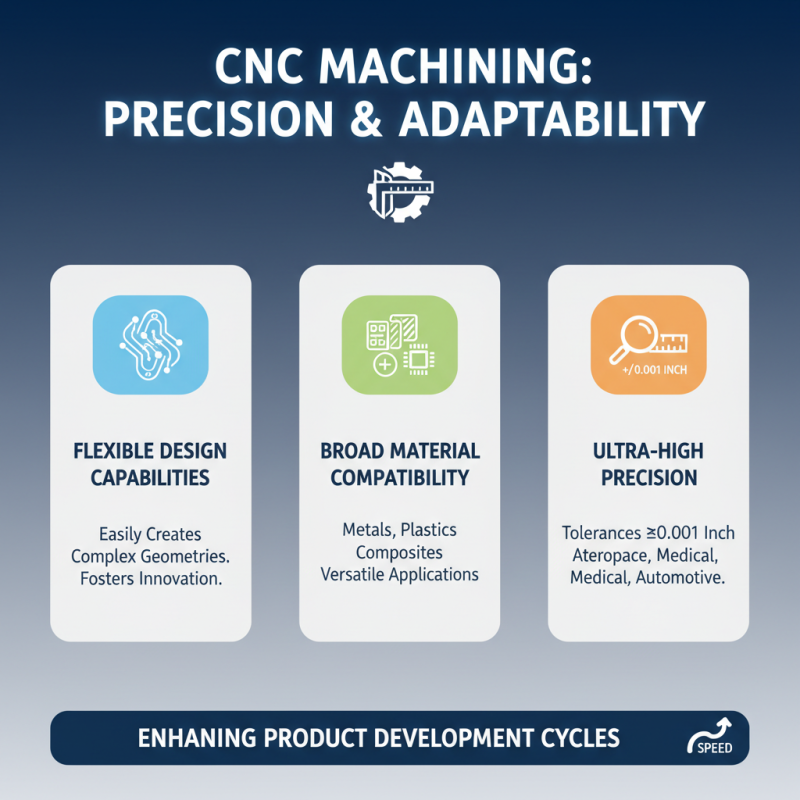

CNC machining stands out in precision manufacturing due to its flexible design capabilities and material compatibility. The technology allows engineers to create complex geometries with ease, providing the freedom to bring innovative ideas to life. According to a report by the International Journal of Advanced Manufacturing Technology, CNC machining can accommodate tolerances as tight as ±0.001 inches, making it ideal for industries that require high precision. This adaptability in design allows companies to manufacture intricate parts for aerospace, automotive, and medical sectors, significantly enhancing product development cycles.

Moreover, CNC machining is compatible with a wide range of materials, including metals, plastics, and composites. A study by Deloitte highlights that over 70% of manufacturers utilize CNC machining because of its versatility in working with multiple materials, from aluminum to titanium alloys. This material diversity not only meets various industry standards but also allows for better performance and longevity of the manufactured components. As industries increasingly demand tailored solutions, the flexibility of CNC machining presents a compelling advantage, enabling manufacturers to respond swiftly to changing market needs while maintaining high-quality output.

CNC machining offers significant advantages in reducing lead time and enhancing efficiency in production cycles, making it a preferred choice for precision manufacturing. By automating the machining process, CNC technology minimizes the duration from concept to completion. Traditional manufacturing methods often involve lengthy manual setups that can lead to delays. In contrast, CNC machines can swiftly switch between tasks with minimal downtime and easily adapt to varying production volumes. This capability allows for faster turnaround times, meeting tight deadlines while maintaining high-quality standards.

Moreover, the precision inherent in CNC machining contributes directly to improved production efficiency. Automated systems ensure consistent accuracy in each machined part, reducing the likelihood of errors that can lead to rework or wasted materials. This level of precision means that parts fit together seamlessly, enhancing the overall assembly process. As a result, manufacturers can optimize production cycles, reduce waste, and maximize resource utilization, all while delivering products that meet or exceed customer expectations. The combination of reduced lead time and improved efficiency makes CNC machining an indispensable tool in modern precision manufacturing.

| Benefit | Description | Impact on Production |

|---|---|---|

| Reduced Lead Time | CNC machining allows for faster production processes compared to traditional manufacturing. | Significantly decreases overall production timeline. |

| Improved Precision | High-level accuracy in producing complex geometries. | Reduces waste and the need for rework, ensuring higher quality products. |

| Operational Efficiency | Streamlined processes and automation lead to reduced human error. | Increases throughput and resource allocation. |

| Material Versatility | Compatible with a wide range of materials including metals, plastics, and composites. | Enables the creation of diverse products meeting various market needs. |

| Cost-Effectiveness | Initial investments offset by reduced material waste and labor costs. | Enhances overall profitability in manufacturing operations. |