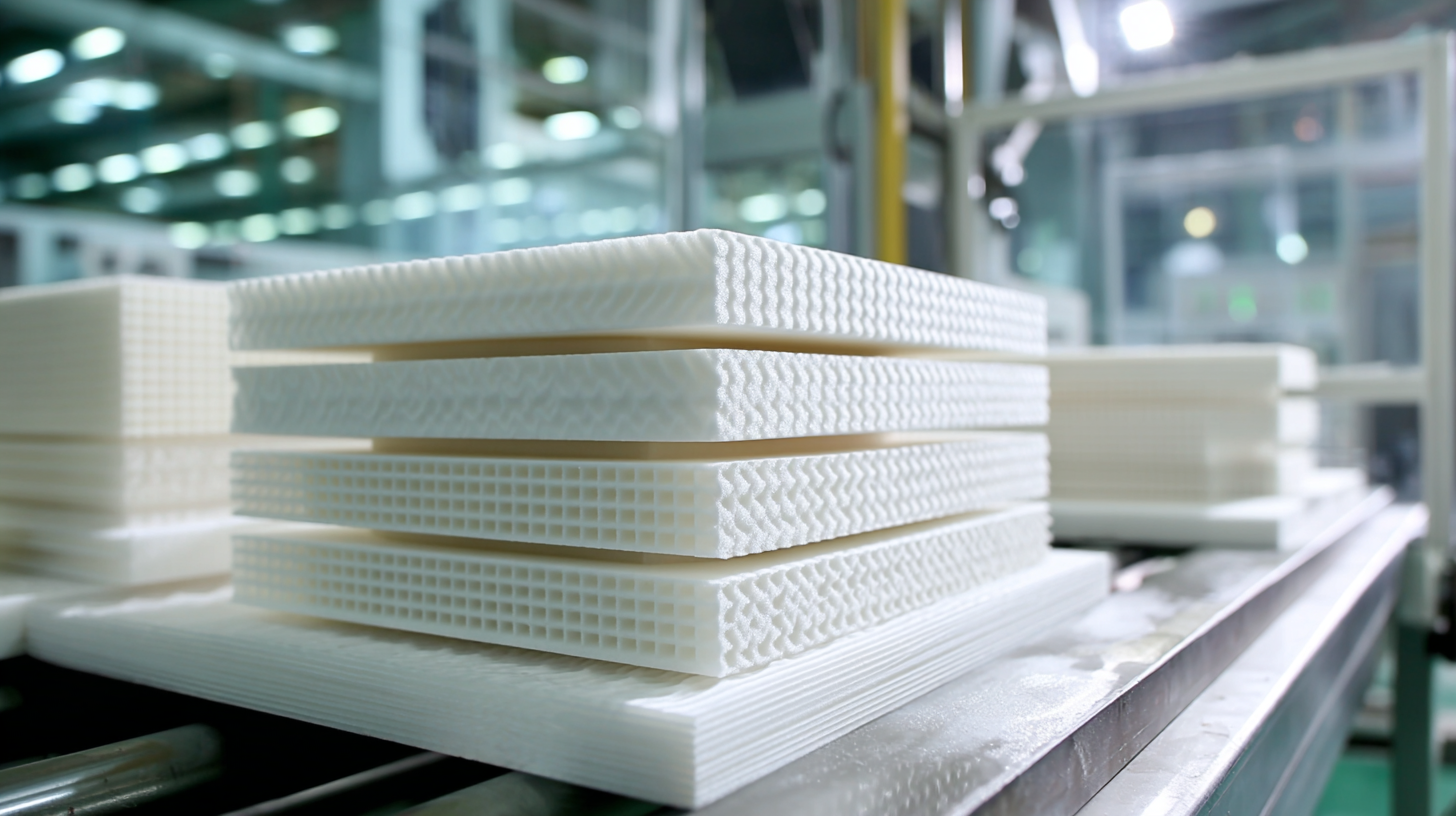

Choosing the right structural foam for your manufacturing needs can significantly impact the quality, durability, and cost-effectiveness of your products. Structural foam is increasingly becoming a preferred material across various industries due to its lightweight properties, excellent strength-to-weight ratio, and exceptional insulation capabilities. However, with the plethora of options available, selecting the appropriate type of structural foam can be overwhelming. Factors such as application requirements, environmental conditions, and budget constraints all play a critical role in this decision-making process. In this blog, we will guide you through the essential considerations and key factors to help you make an informed choice when it comes to structural foam, ensuring that you align material properties with your specific manufacturing objectives.

When considering structural foam for manufacturing needs, it's crucial to begin by clearly identifying your specific requirements. The intended application plays a significant role in the selection process. For example, if you require lightweight components with high impact resistance, you may lean towards polyurethane or polystyrene foams. On the other hand, if thermal insulation or chemical resistance is essential, materials like PVC or polyethylene could be more suitable. Understanding the mechanical properties, such as tensile strength, compressive strength, and flexibility, will also help you to narrow down your options.

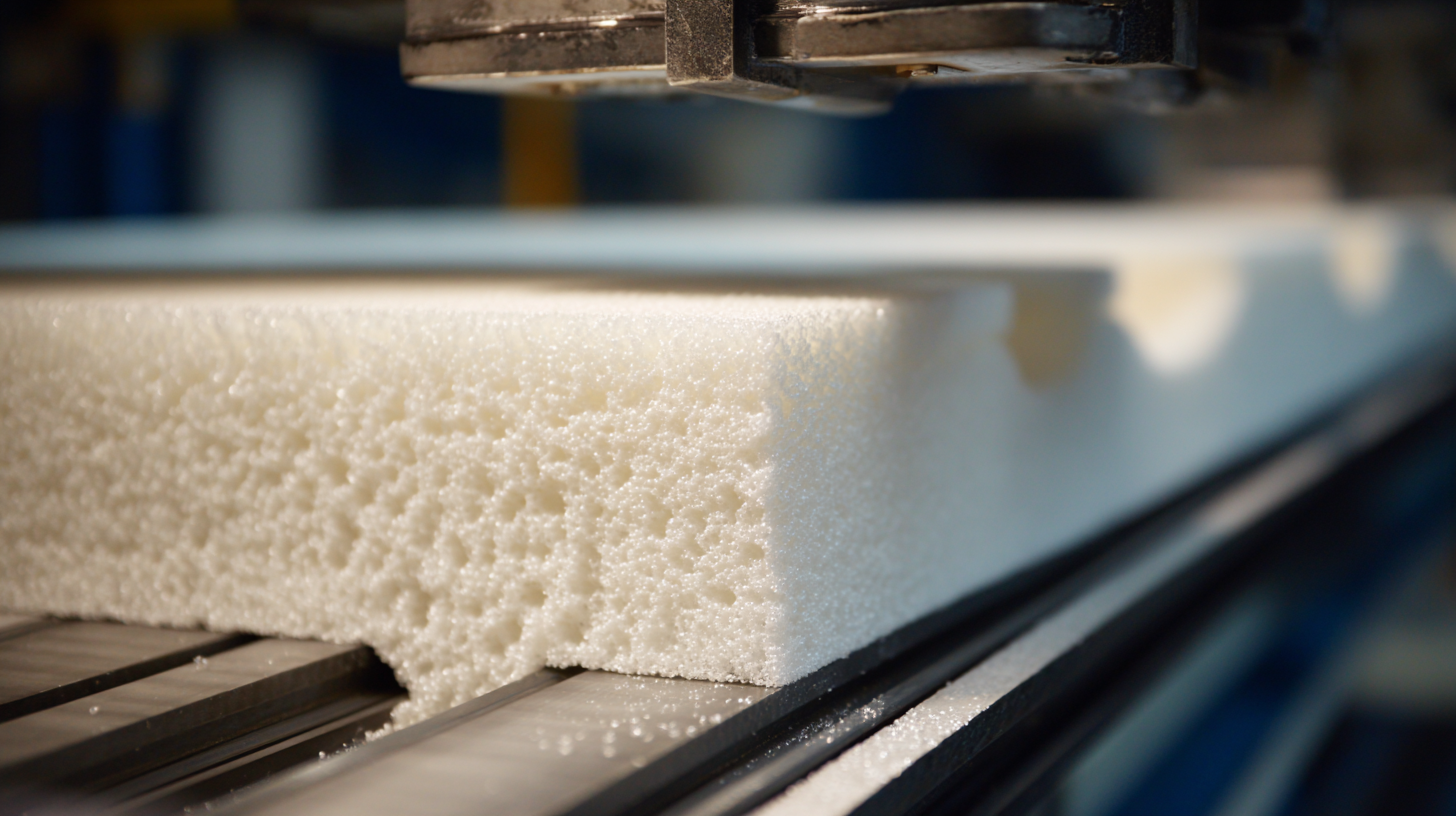

In addition to performance characteristics, evaluating the manufacturing process itself is imperative. Consider the methods of fabrication you will use—whether it’s injection molding, machining, or another technique. Each foam type behaves differently under various processing conditions, influencing the overall efficiency and cost-effectiveness of your production. Furthermore, availability and lead times should not be overlooked; sourcing materials from reliable suppliers is key to maintaining your production schedule. By taking these factors into account, you can make a well-informed decision that aligns with both your manufacturing capabilities and product requirements.

| Parameter | Requirement Type | Suggested Foam Type | Key Characteristics |

|---|---|---|---|

| Density | Lightweight Applications | Low-Density Foam | Improved handling and reduction in weight |

| Compression Strength | Impact Resistance | High-Density Foam | Excellent durability and resistance against deformation |

| Thermal Insulation | Temperature Control | Polyurethane Foam | Excellent thermal resistance and energy efficiency |

| Moisture Resistance | Outdoor Applications | Closed-Cell Foam | Prevents water absorption and mold growth |

| Fire Performance | Safety Regulations | Flame-Retardant Foam | Meets safety standards for flame resistance |

When it comes to selecting the right structural foam material for manufacturing needs, understanding the different types available is crucial. Structural foams can be categorized into various types based on their composition, density, and application. For instance, polyurethane foams are known for their excellent insulation properties and versatility, making them a popular choice for various industries. On the other hand, polystyrene foams offer lightweight and rigid solutions, often used in packaging and construction.

Tips for choosing structural foam include considering the specific requirements of your project, such as strength, thermal resistance, and weight. Think about the environment in which the foam will be used, as some materials may perform better in extreme conditions or high-stress applications. Additionally, evaluate the cost-effectiveness of the foam types, as investing in a higher-quality material can lead to savings over time through enhanced durability and performance.

Another essential aspect is understanding the manufacturing process of the foams. Different techniques, such as extrusion or injection molding, can affect the final product’s properties. Be sure to collaborate with suppliers who can provide insights on how different foams are produced and their implications for your projects, ensuring you make an informed decision tailored to your specific manufacturing needs.

When selecting the right structural foam for manufacturing, it's crucial to focus on key properties that will influence both the performance and sustainability of the final product. Among these properties, density, thermal stability, and mechanical strength stand out as vital considerations. Recent advancements in polyurethane foams, particularly those formulated with bio-polyol blends, highlight an eco-friendly alternative that offers enhanced comfort and performance for automotive seating applications. These innovations reflect the growing demand for materials that align with sustainability goals, potentially reducing environmental impact while maintaining high functional standards.

Additionally, an understanding of composite materials, particularly those integrating natural fibers, provides insights into their lightweight advantages and versatility in various applications. Natural fibers, with features such as low density and corrosion resistance, not only contribute to manufacturing efficiency but also offer an environmentally conscious choice. As industries push towards more sustainable practices, utilizing advancements in fiber-reinforced polymers could significantly contribute to reducing the carbon footprint of manufacturing processes. In the context of structural foams, these evolving technologies allow manufacturers to optimize material selection according to specific performance criteria while embracing a more sustainable future.

When selecting structural foam for manufacturing, cost-effectiveness is often a paramount consideration. According to a recent report by Grand View Research, the global structural foam market is projected to reach $40.24 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.3% from 2020. This highlights the increasing demand, but also the necessity for manufacturers to closely evaluate their options to avoid overspending.

One key factor in assessing cost-effectiveness is the material's performance-to-cost ratio. For instance, polyurethane foam is known for its durability and excellent insulation properties, often leading to lower long-term costs due to energy savings and minimal maintenance requirements. A study published in the Journal of Materials Science found that while initial costs of polyurethane may be higher than other materials, their lifespan and functionality can result in a reduced total cost of ownership. This makes it crucial for manufacturers to conduct a thorough cost-benefit analysis before making a decision, ensuring that the selected structural foam not only fits their budget but also meets performance expectations.

Additionally, evaluating supplier reliability and the potential for bulk purchasing discounts can further enhance cost-effectiveness. Research from MarketsandMarkets indicates that suppliers offering integrated solutions, including logistics and technical support, can help manufacturers reduce their overhead costs. By factoring in these elements, companies can strategically invest in structural foam that aligns well with both their budget and operational efficiency.

When selecting the right supplier for quality structural foam solutions, it’s crucial to consider several factors that can significantly impact your manufacturing processes. Start by evaluating the supplier’s reputation in the industry. Look for testimonials and case studies that showcase their previous work and the satisfaction of their clients. This insight can help you gauge whether they are a reliable partner for your specific needs.

Tip: Always request samples of the structural foam to assess its quality firsthand. Testing the material in real-world applications will allow you to ensure that it meets your performance criteria and is suitable for your manufacturing requirements.

Another important aspect to consider is the supplier's ability to provide customizable solutions. Every manufacturing operation has unique specifications and challenges. A capable supplier should be willing to work closely with you to develop tailored foam solutions that meet your operational demands.

Tip: Ask potential suppliers about their production capabilities and lead times. Understanding how quickly they can deliver custom solutions can give you a competitive edge in your manufacturing timeline.