Choosing the right CNC machining service can feel overwhelming. With numerous options available, it’s essential to select a provider that aligns with your project needs. CNC machining offers precision and efficiency for various industries. However, not all services are created equal.

When evaluating CNC machining providers, consider their expertise and equipment. Some may specialize in certain materials or complex geometries. Gather samples of their work to assess quality. It’s crucial to ask about turnaround times and pricing too. Unexpected delays can derail your project plans.

Maintain a checklist of your requirements. Highlight key aspects like tolerance levels and surface finish. Don’t hesitate to ask questions. Reflect on your priorities and what compromises you can make. This process can be tedious, but a good CNC machining service will enhance your project’s success.

CNC machining services play a pivotal role in modern manufacturing. They offer precision and efficiency that traditional methods might lack. Understanding the basics of CNC machining is essential for anyone considering these services.

CNC stands for Computer Numerical Control. This technology uses computer systems to control machine tools. It can create intricate parts from various materials, like metal or plastic. The process begins with a digital design, which is translated into machine instructions. This ensures exact dimensions and shapes with minimal waste.

However, not all CNC services are the same. Some may have advanced machines, while others might rely on outdated technology. It's crucial to evaluate their capabilities. Look for a service that provides examples of previous work. Understanding their strengths and weaknesses can help you make an informed choice. Being open to discussing your project's needs can lead to better outcomes. Consider your timeline and budget as well, as these can significantly impact your decision.

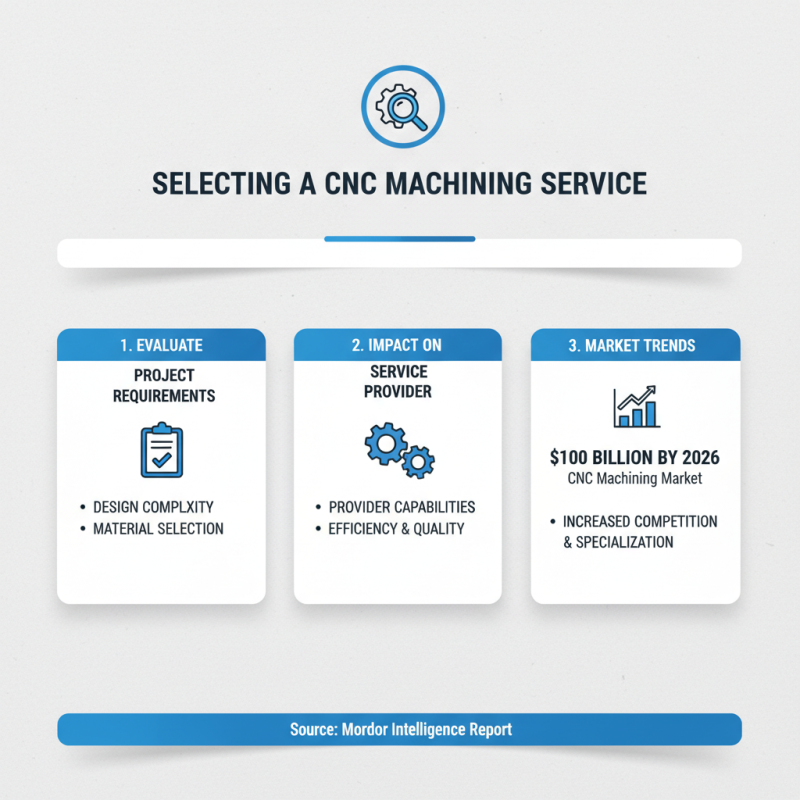

Evaluating project requirements is crucial when selecting a CNC machining service. The complexity of your design significantly impacts the choice of service provider. For instance, a report by Mordor Intelligence reveals that the CNC machining market is expected to reach $100 billion by 2026. This growth suggests increased competition and specialization among providers. Tailoring your choice to their capabilities can enhance efficiency and quality.

Consider the materials you need. Different CNC services specialize in various materials. Aluminum, for instance, is lighter but can be costly. Steel is durable but heavier. A study by Technavio indicates that 36% of industries prefer aluminum for prototypes due to its machinability. Understanding material properties is vital for making an informed decision.

Moreover, assessing deadlines is critical. Some services can handle quick turnaround times, while others may not. Choosing the wrong service could lead to delays, which can be detrimental. You might also overlook post-processing needs. Neglecting these aspects can lead to unexpected costs or quality issues. It's worth reflecting on whether you have adequately considered all these elements before making your choice.

Choosing the right CNC machining service involves various factors. One key factor is the provider's experience. Look for those with a proven track record in your specific industry. Their expertise can influence the quality of your project. A skilled provider understands material properties and production challenges, leading to better outcomes.

Another important aspect is the range of services offered. Some companies focus on specific machining processes while others provide a broader portfolio. It's essential to select a provider that can meet all your project requirements, from prototyping to final production. The ability to handle complex designs is also crucial.

Lastly, consider customer support. A responsive team can make a difference, especially during critical phases. Good communication can clarify project specifications and timelines. It helps avoid misunderstandings that can derail a project. Reflect on these factors as you choose your CNC partner, and remember that every detail counts.

When selecting a CNC machining service, thorough research is paramount. Start by compiling a list of potential companies. Look for those with a solid reputation and relevant experience. According to a recent industry report, 70% of companies prioritize quality and precision. Collect customer reviews to gauge reliability and customer service quality.

Tip: Leverage online platforms to compare machining services. Check their websites for case studies and certifications. Look for companies that use advanced technology, as it often correlates to better results. However, beware of overly polished marketing. Sometimes, claims don't match reality.

Comparing quotes is essential too. A common mistake is focusing solely on cost. While affordability is important, quality should not be compromised. A study indicates that 30% of projects fail due to overlooked quality control. Prioritize companies that offer comprehensive support and communication. Often, the cheapest provider may lead to unexpected costs down the road.

Tip: Ask potential CNC machining services about their machining capabilities. Inquire about materials they work with and their industry experiences. Understanding their limitations can prevent missteps in your project.

| Criteria | Company A | Company B | Company C |

|---|---|---|---|

| Experience (Years) | 10 | 8 | 15 |

| Materials Supported | Aluminum, Steel | Plastic, Steel | Aluminum, Plastic, Brass |

| Max Part Size (mm) | 1000 | 800 | 1200 |

| Lead Time (Days) | 7 | 10 | 6 |

| Pricing (USD per hour) | 75 | 70 | 80 |

| Quality Certifications | ISO 9001 | ISO 9001 | ISO 9001, AS9100 |

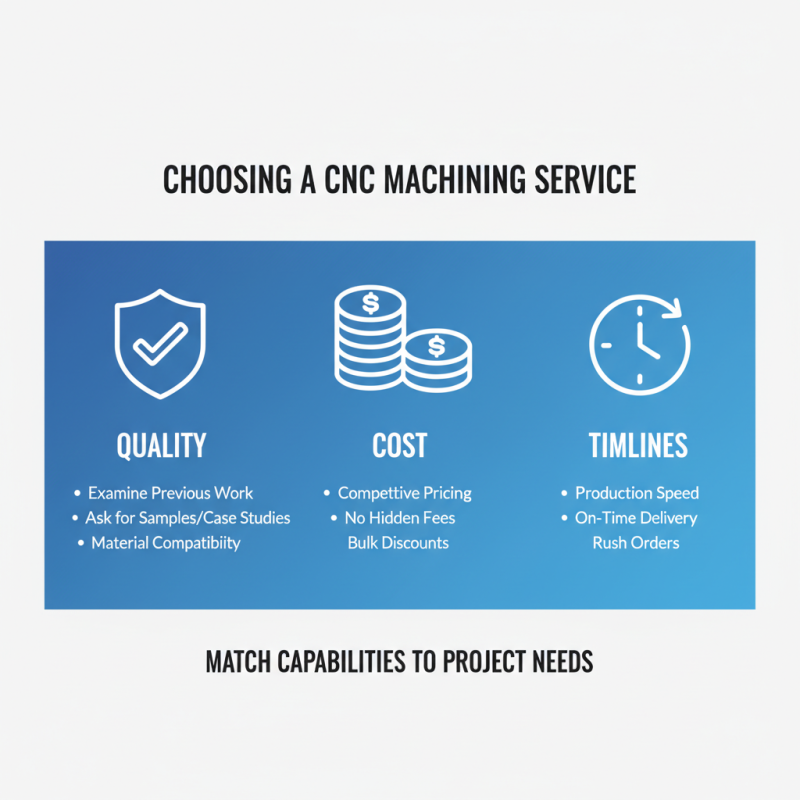

Choosing the right CNC machining service revolves around assessing quality, cost, and timelines. Quality is paramount. Examine their previous work. Ask for samples or case studies. Consider the materials they typically work with. It's essential to see if their capabilities match your project's requirements.

Cost is always a concern. Get quotes from multiple services. Don't just settle for the lowest price. Often, a lower cost might come at the expense of quality. Understand the pricing structure well. Does it include post-processing, or are there hidden fees? These details can greatly affect your budget.

Timelines can make or break your project. Ask potential providers about their lead times. Are they able to meet your deadlines? Sometimes, certain services might promise quick turnarounds. Yet, those promises might lead to rushed work and errors. It's crucial to find a balance between speed and quality. Take the time to communicate clearly with your chosen service. This can prevent misunderstandings down the line.