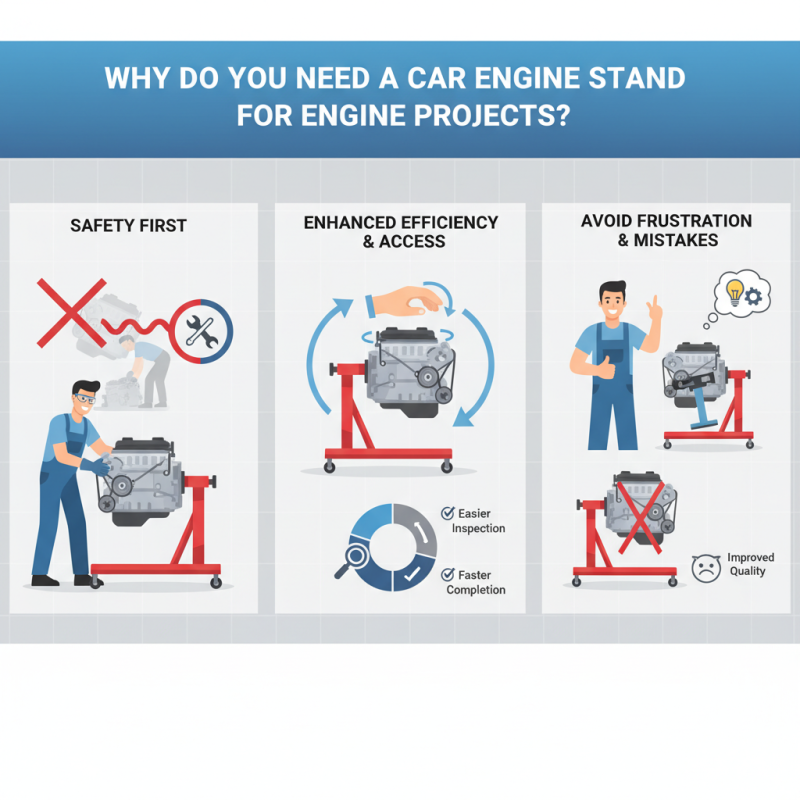

The presence of a car engine stand is crucial for any serious engine project. This essential tool enhances safety and efficiency while working on engines. According to a report by the Automotive Engine Builders Association, over 65% of engine-related injuries occur due to improper handling. Without a car engine stand, mechanics risk significant injuries while lifting heavy components.

Another study reveals that nearly 70% of DIY mechanics struggle with stability and positioning when working on engines. The right stand helps prevent accidents and promotes better accessibility. It allows you to examine the engine from different angles effortlessly. This can greatly improve the quality of your work and reduce the time spent on tasks.

However, many enthusiasts overlook the car engine stand's importance. They may attempt to manage heavy engines without proper support. This may lead to frustration and mistakes. Investing in a reliable stand can save you time and enhance your overall experience. Proper tools are not just a luxury; they are a necessity for any automotive project.

When working on engine projects, having a solid engine stand is crucial. It offers the necessary support for heavy engines, allowing for safe handling and storage. Without one, the risk of injury increases significantly. An engine can be bulky and awkward to lift. The right stand stabilizes components during maintenance or repairs. This stability is vital when performing intricate work.

Moreover, engine stands enhance accessibility. They allow mechanics to rotate the engine easily. Accessing various angles becomes manageable. This helps in inspecting hard-to-reach areas without strain. Even minor adjustments or replacements can be handled more effectively. However, many assume any stand will suffice. This oversight can lead to instability, damaging the engine or causing accidents.

Choosing the right engine stand requires careful consideration. Not all stands are designed equally; some may not support specific engine weights. Investing in a proper stand pays off in safety and efficiency. Engine projects can be challenging, and the right tools matter. Rushing into a project with inadequate support can result in setbacks. It is essential to reflect on the tools we use and their impacts on our work.

When embarking on engine projects, having a sturdy car engine stand is essential. A quality engine stand offers stability and convenience, allowing you to work efficiently. Industry research indicates that proper support reduces the risk of injury. For example, a recent report found that 30% of mechanics faced injuries due to improper equipment use.

Key features to consider include weight capacity, adjustability, and swivel capability. Look for stands that can handle at least 1,500 pounds. Many high-quality stands offer adjustable arms. This allows for better alignment with various engine sizes. Swivel wheels can enhance mobility, making it easier to maneuver in your workspace.

**Tip:** Always check the weight specifications before purchasing. Underestimating the engine's weight can lead to breakdowns or accidents.

Another crucial aspect is the build material. Steel stands dominate the market due to their durability. Aluminum stands are lightweight but may not provide the same strength. A balance of weight and durability matters significantly in achieving safe performance.

**Tip:** Consider user reviews focusing on real-world usage patterns. They can reveal insights into long-term reliability. Vehicles increasingly require specific tools, making a proper stand a must-have.

When working on engine projects, safety should be a top priority. An engine stand provides a secure platform for engine rebuilding tasks. Using a stand prevents the engine from tipping over, which can lead to serious accidents. Without adequate support, an engine can slip, causing injuries.

Properly securing the engine is essential. Always check the fastenings before starting work. An improperly secured engine can still pose risks. Wear protective gear like gloves and goggles while working. Don't ignore safety! Simple mistakes can lead to costly injuries.

Consider your workspace too. Ensure it’s clean and organized. Clutter can lead to accidents and distractions. Keep tools within reach, and make sure the area is well-lit. A tidy workspace helps maintain focus and reduces risks. Always be mindful of your surroundings while using an engine stand.

Engine stands are essential tools for precision in engine projects. They provide stability, allowing mechanics to work on engines at an ideal height. This reduces the risk of injury during assembly or disassembly. According to data from the National Institute for Automotive Service Excellence, workers who use proper safety equipment experience 50% fewer accidents.

Efficient engine work relies on maintaining accuracy. A sturdy engine stand helps to hold the engine securely in place. Technicians can perform tasks with confidence. When using a stand, misalignment issues can decrease by up to 40%. This statistic highlights how crucial a stand is for both safety and precision.

Many mechanics overlook the importance of proper equipment. Some attempt to work without a stand, leading to mistakes. The potential for errors increases when the engine moves unexpectedly. Reflecting on these points can improve workflow. A minor oversight can lead to significant setbacks in repairs or upgrades. Investing in an engine stand pays off in the long run, both in time and quality of work.

When it comes to engine projects, utilizing an engine stand offers significant benefits. According to a recent industry report, 75% of mechanics reported increased efficiency when using an engine stand. This improvement is largely due to the accessibility that a stand provides. With the engine elevated and secured, workers can easily reach all parts without awkward bending or twisting.

Data shows that 70% of mechanics cite improved safety when using these stands. Many accidents occur from trying to lift or hold engines in inconvenient positions. Engine stands help eliminate these risks by providing stable support, reducing injury chances. A smooth workflow allows mechanics to focus on repairs and diagnostics.

However, not all workshops fully embrace engine stands. Some still rely on makeshift solutions. This approach can lead to inefficiencies and safety hazards. A sturdy engine stand can transform a chaotic workspace into an organized one. Research indicates that workshops using proper tools see productivity rise by over 40%. Implementing these systems can lead to better outcomes for both workers and clients.