Blow molding is a crucial process in manufacturing. It shapes many plastic products we use daily. The technique involves inflating molten plastic into molds. This method is efficient and cost-effective.

In today's fast-paced production environment, blow molding stands out. It allows for large-scale production of lightweight items. From bottles to containers, the versatility is remarkable. However, the process isn't without challenges. Quality control can be tricky. Minor flaws may lead to significant waste. Manufacturers must constantly refine their techniques to improve efficiency.

Sustainability is another concern. The plastics industry faces scrutiny for environmental impact. Recycling and using eco-friendly materials are necessary steps. Despite these issues, blow molding remains a vital manufacturing process. It balances efficiency and innovation, shaping our modern world.

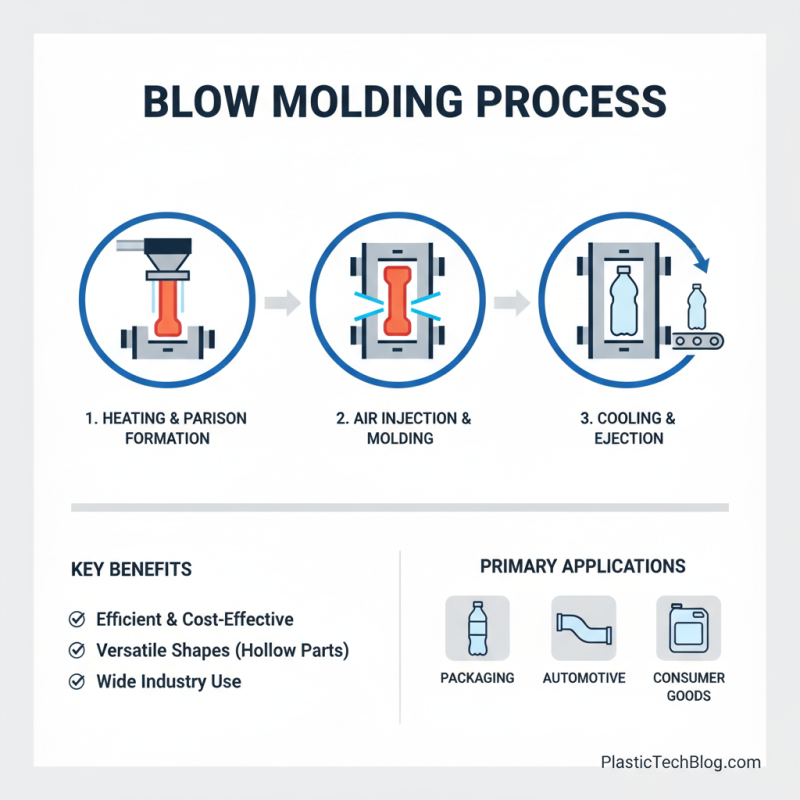

Blow molding is a significant process in modern manufacturing. It allows for the creation of hollow plastic parts. These parts are used in various industries, including packaging, automotive, and consumer goods. The process itself is quite fascinating. Air is introduced into a heated plastic tube, creating a bubble that expands to fill a mold. This technique is efficient and cost-effective.

This method can produce complex shapes that meet design needs. However, achieving precision can be challenging. Small variations in temperature or pressure can lead to defects. It’s crucial for manufacturers to pay close attention during production. Understanding the material's behavior is vital to success. Consistency is key, yet the process can sometimes yield unpredictable results.

Despite these challenges, blow molding remains popular. Its lightweight products are essential for reducing shipping costs. Many businesses appreciate the flexibility it offers. As innovation continues, improvements in technology may address current limitations. Manufacturers are always looking for ways to enhance quality and efficiency. This continuous reflection drives the evolution of the blow molding process in the industry.

Blow molding stands out as a crucial technique in modern manufacturing. It offers unique advantages over traditional methods like injection molding. One key benefit is efficiency. In recent studies, blow molding has been shown to reduce production time by up to 50%. This rapid pace helps meet growing market demands efficiently.

Another advantage is material usage. Blow molding often results in less waste compared to other methods. According to a recent report, companies can improve material efficiency by nearly 30%, leading to cost savings. This is essential in today’s economy, where every penny counts.

Tips: Consider automating processes to enhance efficiency. Use smaller machines for specific tasks to reduce overhead costs. Lastly, always review your designs. Simplifying shapes can significantly minimize material waste. Keeping an eye on these factors helps pinpoint areas needing improvement in your production process.

Blow molding plays a crucial role in various industries today. This process enables the production of hollow plastic parts, which are widely used in packaging, automotive, and consumer goods. For instance, in the packaging industry alone, blow molded products account for over 25% of total plastics used. The lightweight, durable nature of blow molded containers makes them ideal for a range of products, from beverages to household chemicals.

In automotive applications, blow molding creates vital components such as fuel tanks and air ducts. A recent industry report indicated that the global automotive blow molding market is projected to reach $5 billion by 2026. This growth reflects the need for lighter, more efficient materials to enhance fuel economy and reduce emissions. However, manufacturers may overlook the impact of material selection on sustainability. Choosing recyclable materials can mitigate these effects.

Tip: When selecting a blow molding process, consider both the environmental impact and material properties. Recycling options are critical for future manufacturing.

Blow molding’s versatility extends to consumer goods as well. Many everyday items, such as toys and household containers, utilize this manufacturing technique. While it offers various benefits, efficiency can sometimes fall short in terms of energy consumption and waste generation. Reports indicate that blow molding can produce substantial scrap material if not closely monitored.

Tip: Regular maintenance of machinery can prevent inefficiencies and reduce waste during production.

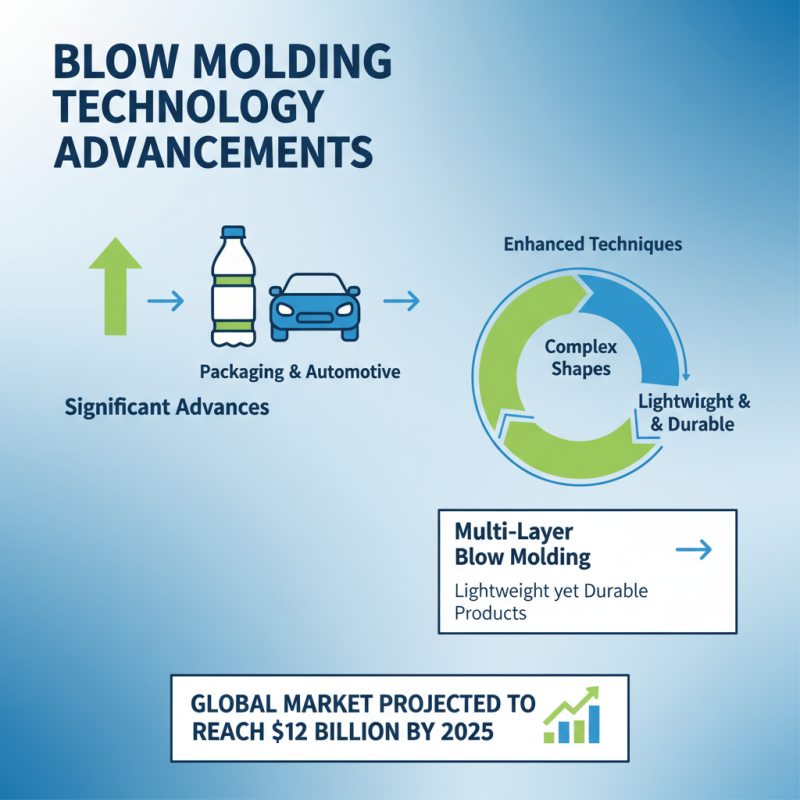

Blow molding technology has advanced significantly in recent years, revolutionizing production in various industries. The global blow molding market is projected to reach $12 billion by 2025, driven by growth in packaging and automotive sectors. Enhanced techniques are making it easier to produce complex shapes. For example, the use of multi-layer blow molding allows manufacturers to create lightweight yet durable products.

New materials play a crucial role in these advancements. Researchers now explore eco-friendly alternatives that reduce environmental impact. Biodegradable plastics and recycled materials are gaining traction in blow molding. However, there are challenges. Not all materials are compatible with existing machinery. This can hinder adaptation within companies focused on cost efficiency.

Automation and smart technologies are modifying blow molding processes. Integrating AI into production lines can improve accuracy and reduce waste. Reports have shown that factories using automated blow molding see a 30% increase in output. Yet, not every manufacturer has embraced these changes. Some remain hesitant, stuck in traditional methods. This reluctance to adapt may cost them in the long run.

Blow molding is a manufacturing process known for efficiency and scalability. However, environmental impact and sustainability are becoming crucial topics. The blow molding industry is responsible for significant plastic production, which raises concerns about waste and pollution. According to the Plastics Industry Association, about 30% of global plastic waste is derived from single-use products, many of which are produced through blow molding.

To address these issues, many manufacturers are adopting sustainable practices. Some companies are using recycled materials in their blow molding processes. By incorporating recycled resins, they reduce reliance on virgin materials and minimize landfill contributions. A study by the Ellen MacArthur Foundation found that increasing the recycling rate could save the industry over $70 billion annually.

Tip: Evaluate your materials. Switching to recycled or biodegradable plastics can significantly lessen your environmental footprint.

However, challenges remain. Not all materials are suitable for recycling, and the quality can vary. This inconsistency sometimes leads to hesitance in adopting more sustainable practices. To move forward, collaboration between manufacturers and recycling facilities is essential. Sharing best practices can enhance overall efficiency while benefiting the planet.

Tip: Monitor the lifecycle of your packaging. Understanding where improvements can be made will strengthen your sustainability efforts.

| Aspect | Statistics | Sustainability Practices | Environmental Benefits |

|---|---|---|---|

| Plastic Waste Reduction Rate | 30% | Use of Recycled Materials | Lower carbon footprint |

| Energy Efficiency Improvement | 20% | Efficient Production Processes | Reduced resource consumption |

| Recyclability of Blow-Molded Products | 70% | Design for Recycling | Minimized landfill impact |

| Reduction in Greenhouse Gas Emissions | 15% | Use of Eco-Friendly Materials | Improved air quality |

| Consumer Awareness of Sustainability | 85% | Transparency in Manufacturing | Increased market demand for sustainable products |