In the fast-evolving landscape of manufacturing, "blow molding" stands out as a transformative process. John Smith, a leading expert in the blow molding industry, once said, “Blow molding revolutionizes how we think about producing plastic products.” This technique offers numerous benefits that shape various industries today.

Blow molding enables the efficient production of lightweight, durable products. It is particularly advantageous for creating hollow parts, such as containers and bottles. The process minimizes waste, a crucial consideration in sustainable manufacturing. However, some may overlook the challenges associated with blow molding. Precision in shaping and control is essential to avoid defects.

As the industry continues to innovate, the advantages of blow molding become increasingly clear. Its role in enhancing productivity and reducing costs cannot be ignored. Yet, companies must also reflect on the implications of adopting this technology. Balancing efficiency with quality remains a critical task for manufacturers embracing blow molding.

Blow molding is a pivotal technique in high-volume production. It efficiently creates complex plastic shapes by inflating molten plastic into molds. According to recent industry reports, the blow molding market is projected to reach $6 billion by 2026. This growth is attributed to the increasing demand for lightweight packaging solutions.

One remarkable aspect of blow molding is material utilization. It offers a production efficiency of up to 90%, which means less waste compared to traditional methods. Industries can save costs while meeting high output demands. However, not all materials are suitable for blow molding. Some plastics may deform under heat and pressure, and choices must be made carefully.

Automotive and consumer goods sectors greatly benefit from blow molding. They leverage this method for producing sturdy parts like fuel tanks and bottles. The speed of production is another advantage. Certain machines can manufacture thousands of units per hour, reducing time in the manufacturing cycle. Yet, companies must also consider potential quality inconsistencies in mass production, as defects can occur. Balancing efficiency with quality remains a challenge that needs addressing.

Blow molding is a popular manufacturing process known for its cost-effectiveness. It allows companies to create complex shapes without excessive material waste. This efficiency considerably lowers production costs, making it attractive for businesses. The method is particularly advantageous for large-scale production runs. It helps businesses save on raw materials and labor.

Moreover, blow molding offers rapid production cycles. This speed can translate to shorter lead times, improving market responsiveness. Manufacturers appreciate the ability to produce high volumes quickly. However, there are challenges to consider. Designing molds can be expensive, leading to a high initial investment. Not every project may justify this upfront cost.

The versatility of blow molding also presents mixed outcomes. It allows for various materials, but some choices may not be suitable for all applications. Companies must evaluate material compatibility carefully. Choosing the wrong type can lead to product failure. Manufacturers sometimes overlook these details, leading to unexpected setbacks. Balancing cost and quality is a delicate dance that requires continuous reflection and adjustment.

Blow molding is crucial in modern manufacturing. It allows industries to create versatile shapes and sizes for various products. According to a report by the Global Market Insights, the blow molding market is expected to reach $34 billion by 2025. This highlights its growing importance in producing everything from containers to automotive parts.

One of the biggest advantages of blow molding is its efficiency. The process can create large volumes quickly, making it ideal for mass production. Manufacturers can produce complex shapes, which are often lightweight yet durable. However, not all designs work well with blow molding techniques. Certain intricate shapes may require additional considerations during the design phase. A failure to account for this can lead to costly revisions.

Material choice also plays a significant role. While polyethylene is commonly used, other materials can introduce challenges. For instance, different polymers might respond differently to heat and pressure. This can affect the final product's quality. It's essential for manufacturers to test and innovate continually. Balancing material properties with design complexity can lead to significant improvements. Emphasizing flexibility will drive future advancements in blow molding techniques.

Blow molding techniques offer impressive design flexibility for manufacturers. This process allows for the creation of complex shapes and intricate details. Industry reports indicate that up to 67% of manufacturers prefer blow molding for customized designs. It can produce lightweight products while maintaining structural integrity. This is crucial in industries like packaging and automotive.

However, challenges still exist. The initial setup and tooling costs can be high. Some manufacturers may hesitate due to these expenses. Yet, the long-term benefits often outweigh these upfront costs. Blow molding can significantly reduce waste and energy consumption. For instance, using the right materials can lower carbon footprints by up to 30%.

Additionally, blow molding accommodates various materials, including plastics and composites. The flexibility in material choice expands design possibilities. It empowers engineers to innovate while optimizing performance. Some companies are still conservative and resist change, missing out on potential advancements. Embracing blow molding techniques could lead to both economic and environmental benefits in manufacturing.

Blow molding stands out in manufacturing for its ability to reduce material waste significantly. Traditional manufacturing methods often lead to excessive scrap. In contrast, blow molding optimizes material usage. A report by the Society of Plastics Engineers noted that blow molding can utilize up to 90% of resin, minimizing waste. This efficiency not only saves materials but also lowers costs.

One key factor is the ability to produce hollow shapes with uniform walls. Blowing air into molten plastic creates a precise product with minimal excess. This precision cuts down on wastage and maximizes resource use. Industry studies show that manufacturers using blow molding reduce waste by up to 35% compared to other methods.

Tip: Regularly assess your production process. Look for areas where excess material is generated. Small changes can lead to significant waste reduction.

Despite these advantages, challenges remain. Some manufacturers may find it difficult to achieve consistent quality in their products. Inconsistent wall thickness can lead to defects, which then generates more waste. Continuous training for operators can help address this issue.

Tip: Invest in employee training. Well-trained staff are more adept at managing production and cutting waste. They are crucial for success in any manufacturing process.

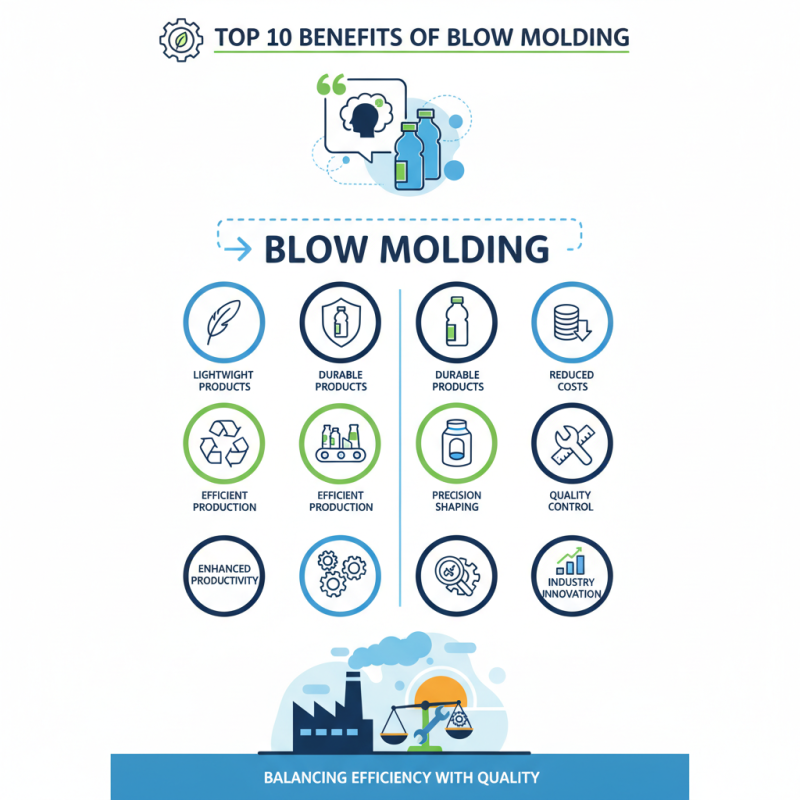

This chart illustrates the key benefits of blow molding in manufacturing, highlighting the reduction of material waste and other advantages.