As the global manufacturing landscape continues to evolve, innovations in aluminum casting technology are setting new industry standards and capabilities. The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing these advancements. According to recent industry reports, the global aluminum casting market is projected to grow at a compound annual growth rate (CAGR) of 4.8%, reaching approximately $80 billion by 2025. This growth is driven by the increasing demand for lightweight and durable materials in sectors such as automotive, aerospace, and construction. The fair not only highlights the latest trends but also facilitates networking among manufacturers, suppliers, and technology providers. By exploring cutting-edge techniques and sustainable practices in aluminum casting, participants can gain valuable insights that will shape the future of the industry, making this event an unmissable opportunity for stakeholders keen on staying ahead in the rapidly advancing market.

At the 138th China Import and Export Fair 2025, attendees were treated to a fascinating array of innovative trends in aluminum casting technologies. This year's event emphasized sustainability and efficiency, showcasing advancements that promise to streamline production processes and reduce waste. From cutting-edge mold designs to eco-friendly alloys, the fair highlighted how the aluminum casting industry is evolving to meet modern demands.

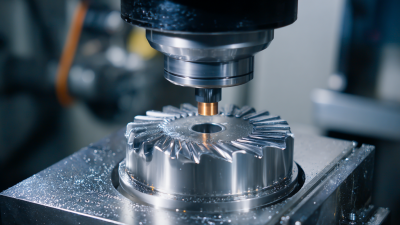

One noteworthy innovation was the introduction of smart casting systems that utilize AI for precision and quality control. These systems allow manufacturers to optimize their operations by predicting failures and minimizing defects, ultimately leading to stronger, lighter, and more durable products. Additionally, several exhibitors demonstrated new techniques that enhance the recyclability of aluminum, which is a crucial aspect given the global push toward sustainable materials.

Tips: When exploring the latest innovations, it's essential to keep an open mind and engage with industry experts. Don’t hesitate to ask questions about specific technologies or strategies that sparked your interest—networking can lead to valuable insights. Furthermore, consider the long-term implications of these advancements on your own business practices, as implementing cutting-edge technologies can significantly enhance your competitive edge.

| Innovation Type | Description | Advantages | Application Areas | Sustainability Impact |

|---|---|---|---|---|

| 3D Printing in Aluminum Casting | Utilization of 3D printing technology to produce complex aluminum parts. | Enhanced design flexibility and reduced material waste. | Automotive, aerospace, and custom tooling. | Lower carbon footprint due to minimized waste. |

| Automated Casting Processes | Implementation of robotics and AI in the casting process. | Increased production efficiency and consistency. | Mass production sectors, such as electronics and appliances. | Reduced energy consumption during production. |

| Lightweight Alloys | Development of new aluminum alloys with improved properties. | Enhanced strength-to-weight ratios and corrosion resistance. | Construction, automotive, and aerospace sectors. | Promotes longer life cycles for products. |

| Die Casting Innovations | Advancements in die materials and cooling techniques. | Higher precision and reduced cycle times. | Consumer goods, automotive parts, and industrial applications. | Less waste generation during the production process. |

The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing advancements within the aluminum casting industry, bringing together key players who are keen to exhibit innovative technologies and sustainable solutions. Notable companies, such as Alcoa and Rio Tinto, are expected to present their latest advancements, contributing to the industry's projected growth. According to a recent report by ResearchAndMarkets, the global aluminum casting market is anticipated to reach $25 billion by 2026, driven primarily by increasing demand from sectors such as automotive, aerospace, and consumer goods. During the fair, attendees will have the opportunity to witness how leading manufacturers are embracing automation and advanced manufacturing techniques, including 3D printing and real-time monitoring systems. These innovations not only enhance production efficiency but also align with the industry's ongoing commitment to sustainability. The demand for lightweight and durable aluminum components is elevating standards in casting processes, with a recent study indicating that the lightweight properties of aluminum can improve fuel efficiency in vehicles by up to 20%. This event promises to highlight the collaborative efforts of industry leaders to push the boundaries of what is possible in aluminum casting and to address the emerging market trends shaping the future of their businesses.

At the 138th China Import and Export Fair in 2025, the aluminum casting industry is poised to showcase a range of sustainable practices and eco-friendly innovations that reflect a growing commitment to environmental responsibility. With the increasing demand for lightweight and durable materials in various applications, aluminum casting has evolved not only in terms of efficiency but also in its environmental impact. The fair will highlight new techniques that significantly reduce waste and energy consumption during the casting process, demonstrating the industry's dedication to sustainability.

Innovators are exploring the use of recycled aluminum, which not only lowers the carbon footprint but also reduces the energy required for production. Additionally, advancements in technology, such as 3D printing and moldless casting, allow for more precise manufacturing processes that minimize material waste. As industry leaders come together to share insights and achievements, the focus on eco-friendly innovations promises to pave the way for a greener future in aluminum casting, encouraging businesses to adopt practices that benefit both the market and the planet.

In 2025, the global aluminum casting market is poised for significant transformation, driven by various market trends. According to a report by Market Research Future, the aluminum casting market is projected to reach approximately $29 billion by 2027, with a compound annual growth rate (CAGR) of around 5.6%. This growth is fueled by the increased demand for lightweight materials in the automotive and aerospace sectors, as manufacturers seek to enhance fuel efficiency and performance. Additionally, the rise in electric vehicle production necessitates innovative casting solutions that can meet stringent weight and strength requirements.

Tips: Manufacturers should invest in advanced casting technologies, such as 3D printing and automation, to streamline production processes and reduce waste. Embracing these innovations can lead to improved product quality and lower production costs.

Another significant trend influencing aluminum casting innovations is the growing emphasis on sustainability and eco-friendly practices. The aluminum industry is increasingly adopting recycling methods to reduce carbon footprints and conserve resources. According to the International Aluminum Institute, nearly 75% of aluminum ever produced is still in use today, highlighting the potential for recycled aluminum casting. Companies that prioritize sustainable practices will not only comply with regulatory requirements but may also gain a competitive edge in an eco-conscious market.

Tips: Collaborating with recycling firms and investing in green technologies can help businesses improve their sustainability profiles while enhancing their market appeal in 2025 and beyond.

The 138th China Import and Export Fair in 2025 is set to be a groundbreaking event for professionals in the aluminum casting industry. With advancements in technology and a growing emphasis on eco-friendly practices, attendees will have the chance to explore innovative products and solutions. However, beyond the exhibition of advancements, the fair offers invaluable networking opportunities for industry professionals. Connecting with peers, suppliers, and potential clients can spark collaborations that may lead to disruptive innovations.

**Tips for Networking:**

To maximize your networking experience, come prepared with a concise introduction about yourself and your organization. Bring plenty of business cards and be open to discussing your challenges and successes. Participate in workshops and panel discussions, as these settings often foster more intimate connections and provide a platform for meaningful dialogue.

As the fair unfolds, industry professionals should engage actively in discussions and exchange ideas. Utilize networking lounges and attend scheduled meet-ups to broaden your contacts. Remember, the relationships you build at events like this can pave the way for future partnerships and enhance your professional growth in the rapidly evolving aluminum casting sector.