In the dynamic landscape of modern manufacturing, the utilization of injection molded parts has emerged as a pivotal strategy for enhancing efficiency and product quality. According to a report by Grand View Research, the global injection molding market is projected to reach $469.6 billion by 2027, driven by the increasing demand for precision-engineered components across industries such as automotive, consumer goods, and electronics. Injection molded parts offer significant advantages, including reduced lead times, lower production costs, and the ability to create complex geometries with high repeatability.

Moreover, the versatility of materials used in injection molding—ranging from thermoplastics to advanced composites—enables manufacturers to cater to specific application requirements, further solidifying the role of injection molded parts in driving innovation and sustainability in manufacturing processes.

Moreover, the versatility of materials used in injection molding—ranging from thermoplastics to advanced composites—enables manufacturers to cater to specific application requirements, further solidifying the role of injection molded parts in driving innovation and sustainability in manufacturing processes.

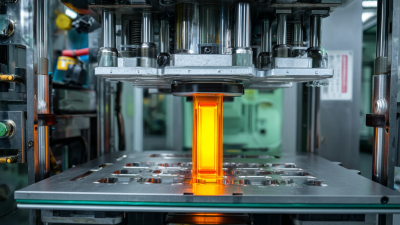

Injection molding is a pivotal manufacturing process that allows for the efficient production of complex parts. The process begins with the melting of plastic pellets, which are then injected into a mold under high pressure. This allows for the creation of intricate designs that would be difficult or impossible to achieve with other manufacturing methods. According to a report by Grand View Research, the global injection molding market was valued at approximately $200 billion in 2022 and is projected to expand at a CAGR of around 4.9% from 2023 to 2030. This growth underscores the widespread adoption of injection molding in various industries, including automotive, consumer goods, and healthcare.

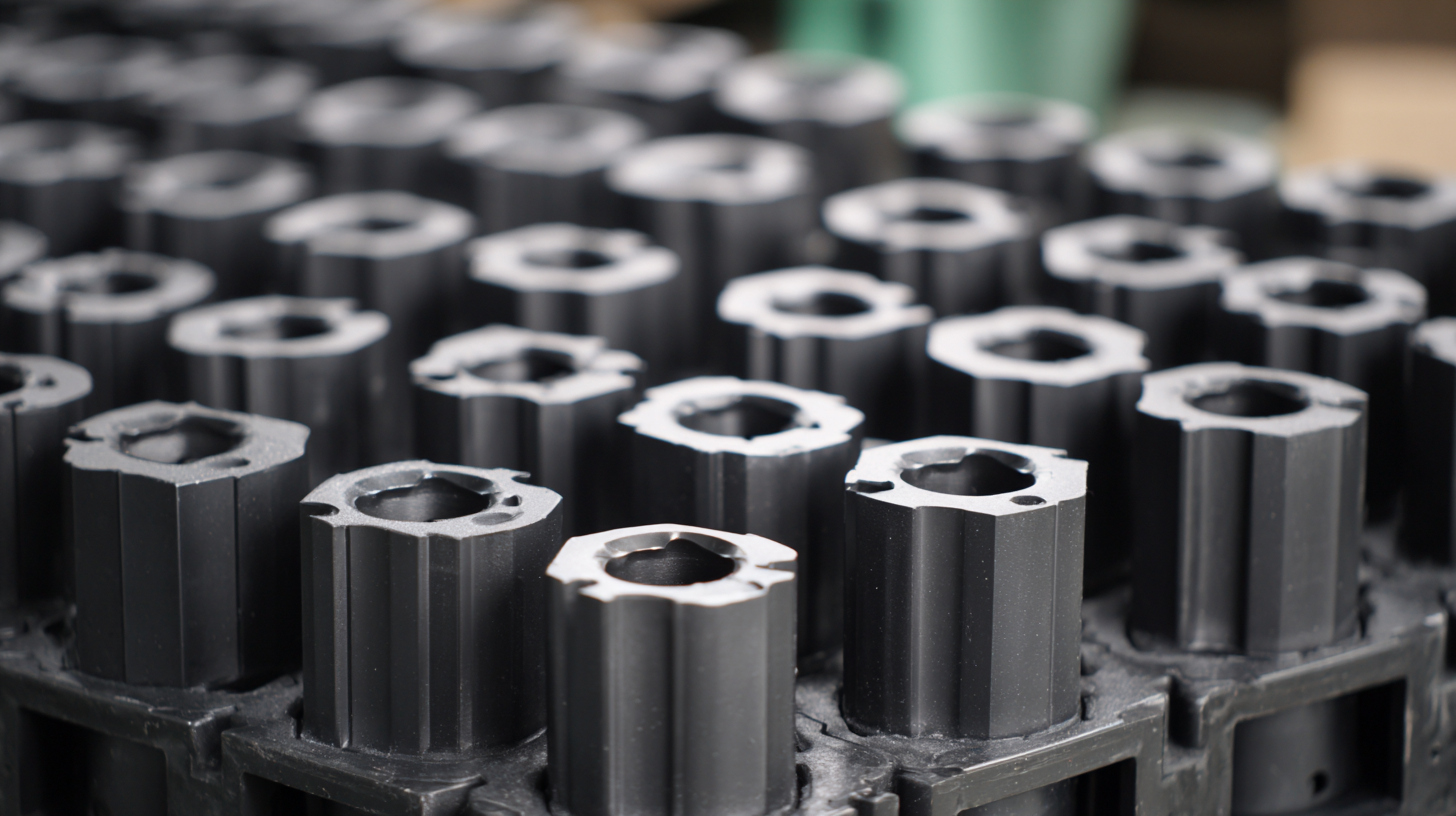

One of the significant advantages of injection molding is its ability to produce high volumes of parts with consistent quality. Once a mold is created, it can be used to produce thousands of identical parts, reducing per-unit costs dramatically. A 2021 study by Mordor Intelligence highlights that the accuracy and repeatability of injection molding can lead to a reduction in production waste by up to 25%, making it an environmentally friendly choice as well. Additionally, advancements in materials and technology, such as the use of biodegradable plastics and improved mold designs, are expanding the capabilities and applications of this manufacturing process, making it more viable for a range of industries looking to innovate and improve efficiency.

Injection molded parts play a crucial role in enhancing manufacturing efficiency across various industries. One of the key benefits of this method is its ability to produce complex shapes with high accuracy. This precision reduces the need for extensive machining or finishing processes, allowing manufacturers to save time and resources. Additionally, the repeatability of injection molding ensures that each part is consistent in quality, minimizing the risk of defects and contributing to smooth production workflows.

Another significant advantage is the scalability offered by injection molding. Once a mold is created, it can be used to produce a large volume of parts quickly and economically. This is particularly beneficial for industries facing high demand, as it enables rapid response to market needs. Furthermore, the material versatility inherent in injection molding allows for a wide range of polymers to be used, which can be selected based on specific performance characteristics required for different applications, from automotive components to consumer products. This adaptability not only enhances efficiency but also fosters innovation in product design and functionality.

Injection molding has emerged as a leading method in modern manufacturing, surpassing traditional production techniques in various aspects. In a comparative analysis, it is important to highlight that injection molding allows for higher precision and repeatability. According to a report by Grand View Research, the global injection molding market size was valued at $236.7 billion in 2021 and is expected to grow at a CAGR of 5.2% from 2022 to 2030. This growth is largely attributed to the increased efficiency and cost-effectiveness that injection molding provides over traditional methods such as machining and die casting.

One of the primary advantages of injection molding is the ability to produce complex geometries with minimal waste. Traditional manufacturing methods often require extensive machining processes that can generate significant material waste. For instance, a study from the American Society for Quality (ASQ) suggests that injection molding can reduce material waste by up to 70% compared to traditional methods. This not only decreases production costs but also aligns with sustainable manufacturing goals sought by many organizations today.

Tips: When considering the shift to injection molding, it’s essential to invest in proper tooling and design optimization. This upfront cost can lead to substantial savings in both time and resources in the long run. Additionally, ensure to partner with experienced manufacturers who can provide insights into best practices and material selection, aligning your production goals with industry standards.

When designing injection molded parts, several critical considerations can significantly affect the efficiency and quality of the final product. One primary factor is material selection, as different thermoplastics and thermosetting plastics offer varying mechanical properties, such as tensile strength and impact resistance. According to a report by the Plastics Industry Association, over 30% of manufacturers cite material properties as a significant determinant in ensuring longevity and functionality in their products. For example, using high-density polyethylene (HDPE) can enhance durability in products intended for heavy use.

Another crucial design consideration is the part geometry. Engineering design must consider aspects such as wall thickness, draft angles, and rib placement to facilitate the injection molding process. The Society of Plastics Engineers emphasizes that non-uniform wall thickness can lead to warping during cooling, while proper draft angles can simplify mold release, thereby reducing cycle times. A 2022 study published by Deloitte highlighted that optimized design can improve production efficiency by up to 20%, indicating that thoughtful design is not just an aesthetic choice but a pathway to maximizing performance and minimizing costs.

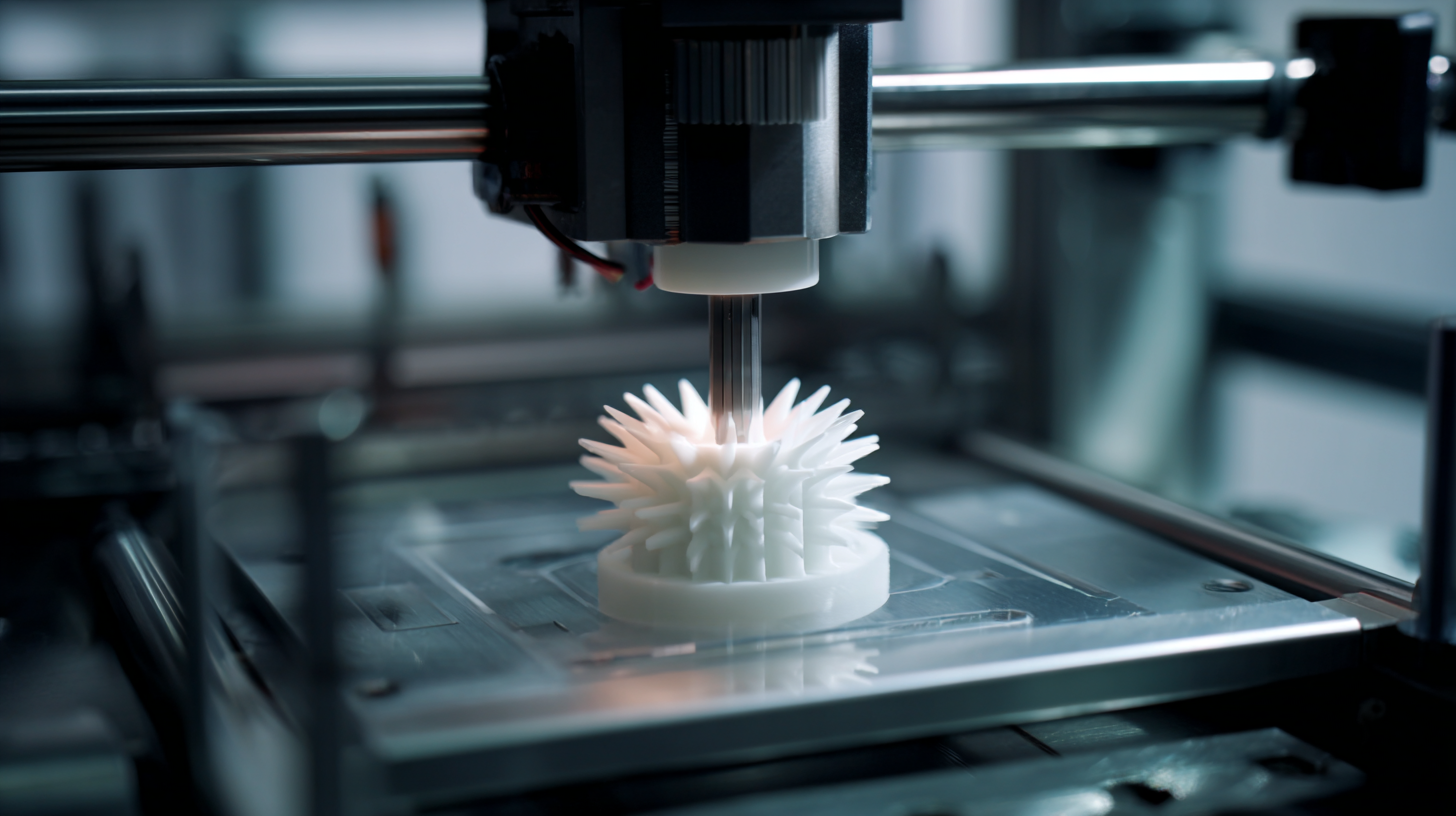

The landscape of injection molding is rapidly evolving with the advent of new technologies and methodologies. One of the most significant trends is the integration of automation and robotics in the manufacturing process. These innovations not only enhance precision and efficiency but also reduce labor costs and lead times. Advanced robotic systems can handle complex tasks such as part inspection and robotic assembly, enabling manufacturers to achieve higher levels of quality control and operational flexibility.

Another noteworthy advancement is the development of sustainable materials for injection molding. As industries face increasing pressure to minimize their environmental impact, the use of bio-based polymers and recycled materials is becoming more prevalent. These materials not only meet consumer demand for sustainability but also offer comparable performance characteristics to traditional plastics. Additionally, innovations in material science are leading to composites with superior strength and lightweight properties, which are particularly beneficial in sectors such as automotive and aerospace.

The future of injection molding also looks promising with the rise of smart manufacturing technologies, including the Internet of Things (IoT) and advanced data analytics. These technologies enable real-time monitoring and predictive maintenance, thereby improving production efficiency and minimizing downtime. As manufacturers continue to adopt these innovations, the potential for improved design capabilities and enhanced product performance will significantly reshape the injection molding industry, offering exciting opportunities for growth and development.

| Dimension | Advantages | Future Trends |

|---|---|---|

| Material Variety | Wide range of materials available, including plastics, metals, and composites. | Development of new bio-based materials for sustainability. |

| Production Speed | Fast cycle times leading to higher output and efficiency. | Integration of artificial intelligence to optimize production speed. |

| Design Flexibility | Ability to create complex shapes and designs with high precision. | Advancements in 3D printing technology for rapid prototyping of molds. |

| Cost Efficiency | Reduced labor costs and high volume production lower per-unit cost. | Emergence of on-demand manufacturing reducing waste and stock costs. |

| Quality Control | Consistent quality with low tolerance variations across production. | Use of smart sensors for real-time quality monitoring. |