In the fast-paced world of manufacturing, the blow molding machine plays a crucial role. These machines create hollow plastic parts used in various industries. The innovation in blow molding technology continuously shapes the market.

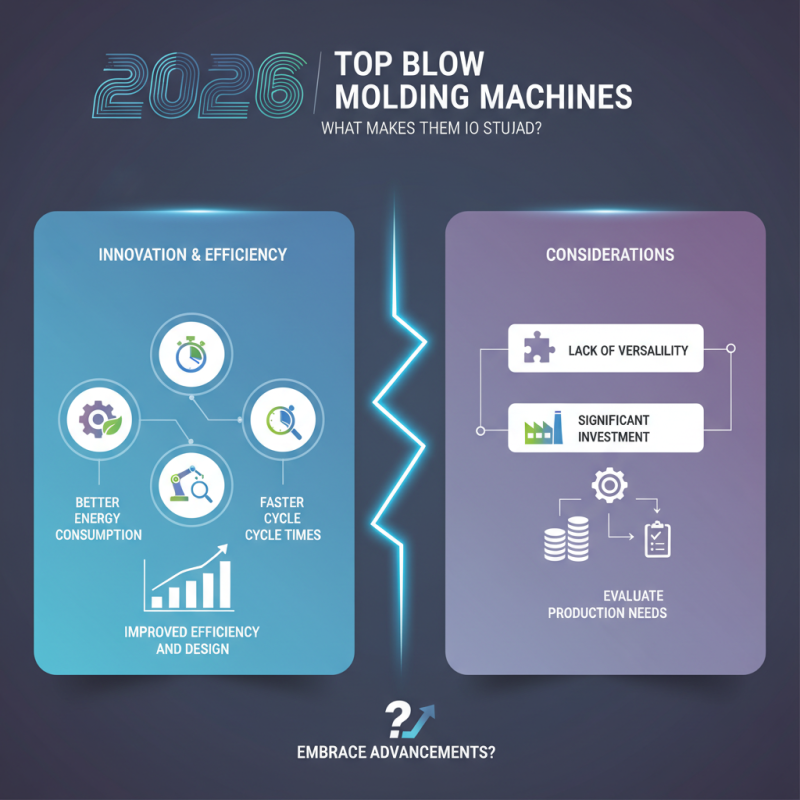

The 2026 models stand out with improved efficiency and design. They offer better energy consumption and faster cycle times. Users should pay attention to features like automation and precision. However, not every machine meets the specific needs of every business. Some might find a lack of versatility in certain models.

A blow molding machine can be a significant investment. Businesses must evaluate their production requirements carefully. Understanding the features that distinguish these machines will help manufacturers make informed decisions. Are they ready to embrace the advancements of 2026?

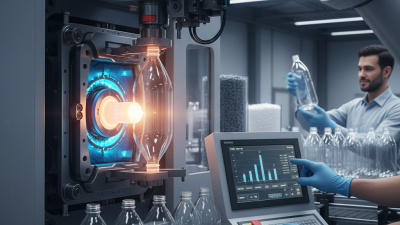

In 2026, the blow molding industry is showcasing advanced machines that are set to transform production. The latest models offer more efficiency and sustainability. They utilize advanced technology to create complex shapes with precision. Manufacturers are looking for ways to minimize waste. This is crucial in today’s eco-conscious market.

Tips: Regular maintenance is essential for optimal performance. Check for wear and tear frequently. Streamlining your production process can help increase overall productivity. Invest in training for your operators. Knowledgeable staff can significantly improve machine performance.

Many machines now come with features like automation and smart technology. These innovations not only save time but also reduce errors. However, adapting to these modern tools can be challenging. Some companies struggle with integration and staff training. It's a vital area that needs attention to avoid setbacks. Continuous learning and adaptation are key in this fast-paced environment.

| Machine Model | Production Capacity (Units/hour) | Type (Extrusion/Injection) | Key Features | Energy Efficiency Rating |

|---|---|---|---|---|

| Model A | 800 | Extrusion | Advanced automation, quick changeover | A+ |

| Model B | 600 | Injection | High precision, low waste | A |

| Model C | 1000 | Extrusion | Compact design, user-friendly interface | A++ |

| Model D | 750 | Injection | Enhanced thermal management, robust construction | B+ |

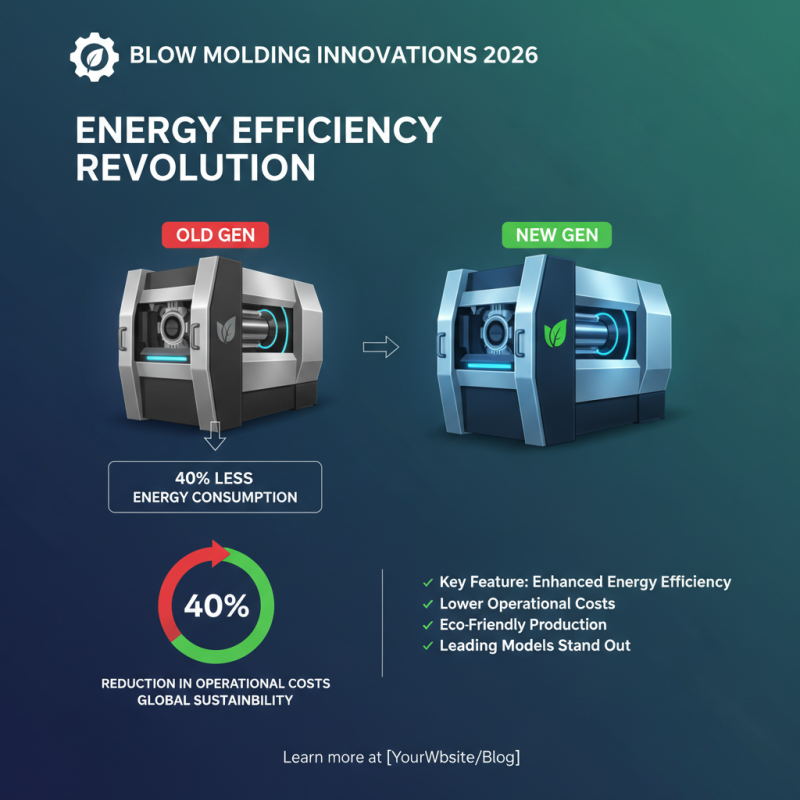

In 2026, the blow molding machine market showcases remarkable advancements. Key features distinguish the leading models among competitors. Enhanced energy efficiency is one standout aspect. Studies show that energy consumption in blow molding can be reduced by up to 40% compared to previous generations. This significant decrease not only lowers operational costs but also aligns with global sustainability initiatives.

Another critical aspect is automation. The latest blow molding machines now integrate advanced robotics for precise operations. This technology reduces human error and increases production speed. In fact, data indicates that manufacturers utilizing automation report a 30% rise in output. However, the transition to automation presents challenges. Training staff and maintaining machines require ongoing investment.

Moreover, the versatility of new blow molding machines cannot be ignored. They now support a wide range of materials. From PET to HDPE, manufacturers can tailor products to meet diverse needs. Still, adapting to multiple material types adds complexity to the production process. Balancing quality with flexibility demands careful consideration. Each choice impacts overall productivity and product integrity. These key features mark the 2026 blow molding machines, but they also invite reflection on the industry's future.

Blow molding machines are evolving rapidly. In 2026, technological innovations are at the forefront. These advancements are enhancing efficiency and reducing waste. New materials are being used. They allow for lighter, stronger products. This shift is crucial for sustainability.

Energy efficiency is another key benefit. Advanced machines consume less power. This cuts costs and reduces the carbon footprint. Automation is also improving cycle times. With less manual intervention, production becomes faster. The integration of IoT is significant, too. Machines can now monitor performance in real-time, identifying inefficiencies.

Tips: Regular maintenance is important. It keeps machines running optimally. Operators should be trained to spot issues early. Consider investing in training programs. It leads to better handling of technology, resulting in fewer errors. Embrace innovation, but don’t overlook the basics. Small mistakes can lead to bigger problems. Balancing tradition and technology is essential for success.

The blow molding industry is evolving rapidly. In 2026, the top machines not only prioritize efficiency but also cost-effectiveness. Performance parameters such as cycle time and energy consumption are crucial. Manufacturers must analyze these factors carefully. A machine may promise high output but could cost more in the long run due to energy waste.

Operational costs are often a hidden challenge. While a new machine may have a lower purchase price, maintenance expenses can add up quickly. Comparing long-term performance is essential. Factors like material compatibility and ease of maintenance should not be overlooked. Some machines may excel in speed but falter in overall durability.

Selecting the right machine requires thorough evaluation. It’s easy to be swayed by flashy features, yet these do not always lead to profitability. Real-world testing reveals that some machines fall short of their initial claims. Insights from current users can be invaluable. Businesses must weigh features against actual performance data to make informed decisions.

The blow molding industry is poised for transformation post-2026. As sustainability demands rise, companies are innovating to reduce waste. Reports indicate that eco-friendly materials will dominate over 30% of production processes by 2028. The integration of bio-based resins is gaining momentum. This shift allows manufacturers to lower their carbon footprints significantly.

Automation and smart technology are altering operational efficiency. Predictive maintenance tools can reduce downtime by up to 25%. Machinery equipped with AI will enhance error detection and boost productivity. These advancements are crucial as production costs skyrocket. However, some manufacturers might struggle to keep up with these rapid changes.

Tip: Stay informed about emerging technologies. Regularly evaluate your machinery. This ensures your operations remain competitive in a fast-changing landscape. Embracing ongoing training for staff is also essential. The workforce must adapt alongside technology.

While advancements are exciting, challenges remain. Integrating new technologies requires substantial investment. Not every facility may afford these upgrades. A careful assessment of return on investment is necessary. Many businesses may overlook this crucial analysis. Understanding both risks and rewards can guide better decisions.